High Performance

The ProJet® MJP 3600 Series is a MultiJet Printing (MJP) plastic 3D printer series designed to create high fidelity and high-performance parts with:

- An affordable price

- An office-friendly footprint

- Easy part processing

The ProJet® MJP 3600 Series is a MultiJet Printing (MJP) plastic 3D printer series designed to create high fidelity and high-performance parts with:

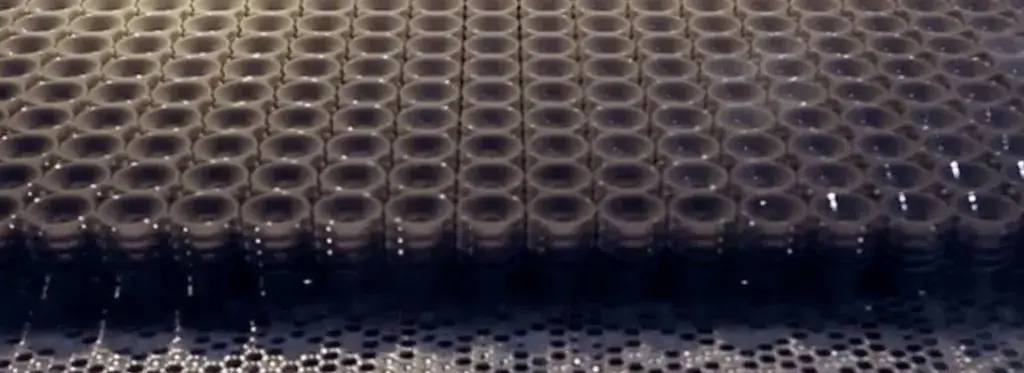

Multi-Jet Precision Parts

Get fine details and smooth finishes like no other 3D printer with the ProJet MJP 3600 series:

Part accuracy and material performances perfectly suit rapid tooling applications

Produce more parts quickly with print speeds up to 2x faster than similar class printers. And with high capacity build volume and automated batch processing, you can increase flexibility and accelerate design repetition and validation for better product quality.

Accelerate product development with rapid functional prototypes iterations

Choose from a variety of available VisiJet® MultiJet 3D printing materials to create high-performance plastic designs that are durable, watertight, heat resistant, bio-compatible, and much more.

MJP parts simulate the look and feel of many injection molded plastics to allow visual assessment and test functionality

Office compatible and easy to use, the ProJet MJP 3600 Series offers a mostly hands-off unattended process from file upload to finished part. With a streamlined and safe batch post-processing unlike other competing 3D MultiJet printers, you can create intricate finished parts up to 4x faster.

Effective support removal enables greater geometric freedom

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

Large format, multi-material composite parts in a single build

MultiJet printing quality, speed and ease of use made accessible