Integrated, Reliable and Proven

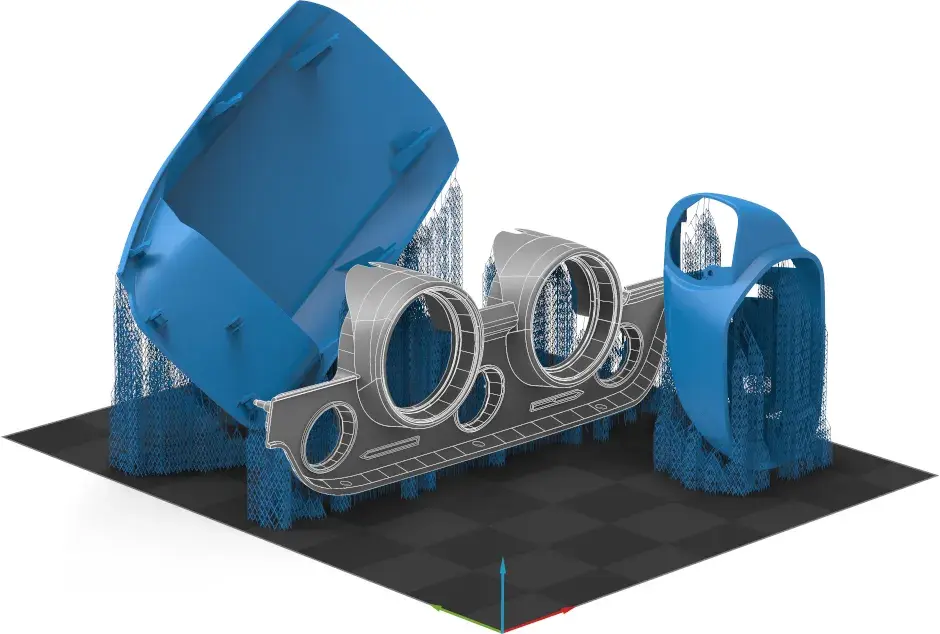

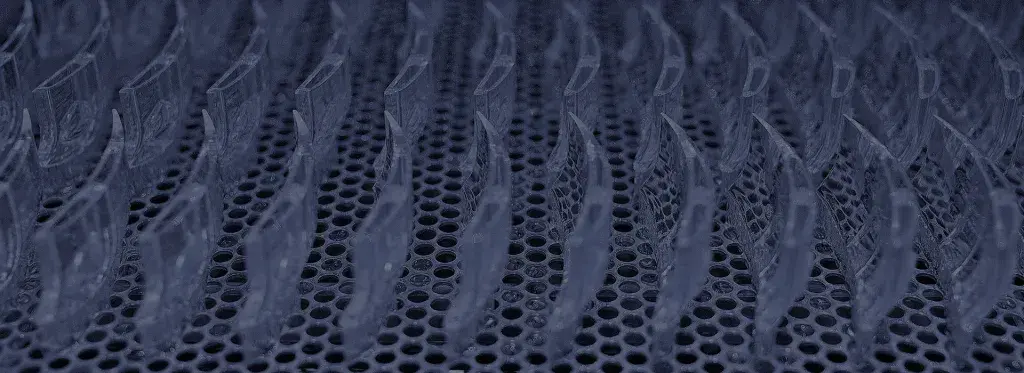

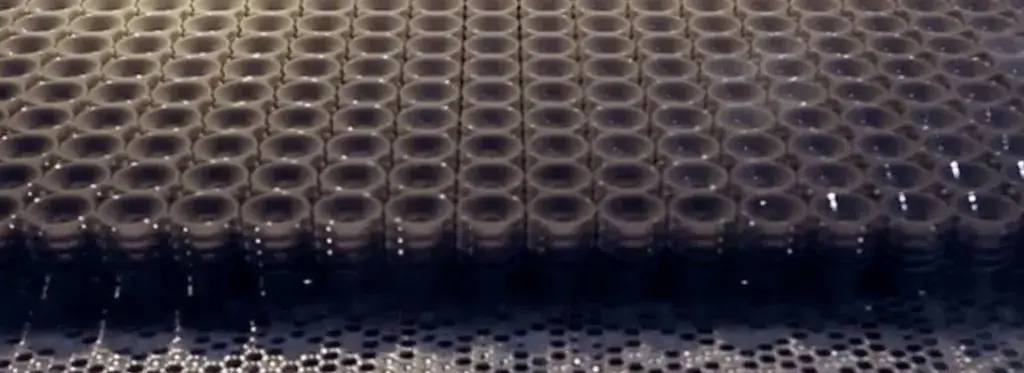

The ProJet® 7000 HD 3D printer from 3D Systems gives you one point of contact to support your prototyping and manufacturing applications and daily use of our gold standard technology. Customized to our specific print engine, the broad spectrum of Accura® SLA resins generate the consistency and mechanical properties required of each material. Our SLA printers have high uptime numbers, while 3D Connect™ Service provides a new level of management in 3D production. This secure cloud-based connection to 3D Systems service teams for proactive and preventative support enables better service, improves uptime and delivers production assurance for your system.