You can order a lot of things online these days, and now that includes cadavers. If you’re wondering how this could possibly be sane or sanitary, let alone legal, the operative magic words are “3D printed.”

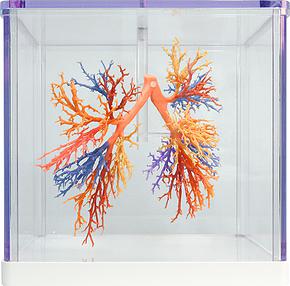

In an effort to provide medical students and future surgeons with adequate, safe and accurate training materials, Australia’s Monash University has produced the first commercially available cadaver kit of realistic, full-color 3D printed body parts using the ProJet® 660 and ProJet 4500 3D printers. The Monash series also includes anatomies that are unobtainable via natural observation, such as 3D close-ups of brain vasculature, or the bronchial tree pictured to the right.

Though some may think a practitioner couldn’t be adequately prepared with anything less than an actual human cadaver, the alternative of nothing at all is all too real. Obtaining and storing human cadavers is a process and ordeal, and it is not only strictly regulated, but expensive. For many programs, issues surrounding supply, cost and logistics pose a daunting obstacle. Yet a medical student foregoing educational exposure to human anatomy in its full physicality is nearly unthinkable. Paul McMenamin, director of the Centre for Human Anatomy Education at Monash Univeristy believes these 3D printed kits will revolutionize medical learning by giving anytime access to students without the red tape.

According to McMenamin, full color is essential to the success of the kits and the necessary precision and accuracy could not be achieved without the photorealistic results of the ProJet 660 and ProJet 4500 3D printers. Because anatomical color communicates important information, fidelity to all shades and variation is critical for reliable learning. Until McMenamin’s department acquired 3D Systems’ machines, he says the technology simply was not there.