CHALLENGE

Maintain even temperatures using conformally-cooled injection molds.

SOLUTION

- Cimatron® integrated CAD/CAM software by 3D Systems

- Geomagic® Control X™ inspection and metrology software by 3D Systems

- LaserForm® 17-4PH (B) stainless steel material by 3D Systems

- Moldex3D® plastic injection molding simulation software

- ProX® DMP 200 metal 3D printer by 3D Systems

RESULTS

- Reduced injection molding cycle times by 22%.

- Eliminated 30-40 hours of mold post-processing time.

- Reduced costs by 18%.

Since the inception of industrial injection molding, keeping an even temperature on the surface of the mold has been a constant challenge.

In their quest to maintain even temperatures, manufacturers have used baffles, bubbles, and heat pipes; they have laminated blocks together and added complex drilling setups to their molds.

Over the last decade or so, conformal cooling—designing cooling channels that naturally follow the contours of a part—has been positioned as a solution for controlling injection-molding temperatures. But conformal cooling adds new layers of design and production complexity to the mold-making process, placing it beyond the means of most shops.

Rock-Solid Methodology

Bastech—an Ohio-based, one-source solution provider for shop floor, additive manufacturing services, and equipment sales—has wrestled with temperature issues, but believes it has found a way to introduce a new level of simplicity, efficiency, and economy to conformal cooling. Its research is aided by its status as a 3D Systems Authorized Gold Partner, giving it access to the latest 3D printing technologies and intelligence.

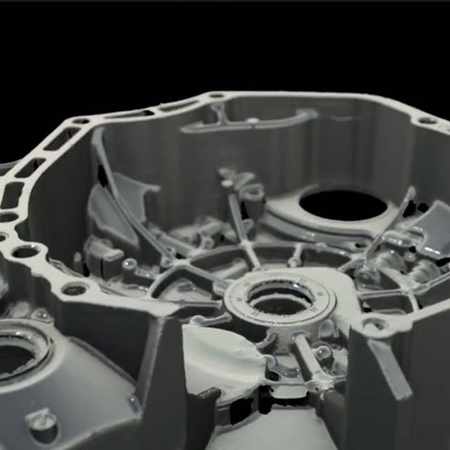

The Bastech breakthrough, documented in two recent benchmark tests, is based on Cimatron CAD/CAM software and the ProX DMP 200 3D printer. Bastech performs simulations for the conformal cooling mold designs using Moldex3D software, a 3D Systems partner, and inspects the completed direct metal printing (DMP) molds using Geomagic Control X inspection and metrology software.

The process represents an end-to-end manufacturing solution with easy integration between the digital and physical worlds, all powered by 3D Systems products.

"The combination of powerful software designed to leverage the full capabilities of 3D printing with printers that deliver a fully dense metal part with smooth surfaces and limited post processing provides a rock-solid methodology for building customized cooling molds," says Bastech CEO Ben Staub.

Design and Analysis Automation

The first Bastech benchmark compared two very similar parts in terms of volume, size, and design configuration. Bastech designed one with a conformal core and then 3D printed the part; it designed the other with a standard spiral baffle configuration and manufactured the part conventionally.

Bastech created the conformal cooling design with Cimatron software that covers the entire mold-making cycle—from quoting, to design, to applying engineering changes, to NC and EDM programming. Cimatron includes cooling design and analysis capabilities that support both traditionally drilled cooling channels and conformal cooling channels for manufacturing using 3D printing technologies.

Through close integration with Moldex3D, injection mold designers working in Cimatron have the ability to perform automated mold-filling analysis to optimize cooling channel layout.

"The combination of Cimatron and Moldex delivers expert software to help less-experienced engineers create better-quality designs," says Staub. "This is a major consideration as the demand for experienced toolmakers is much larger than the dwindling supply."

"Designing for 3D printing requires an understanding of structural support design to accomplish true requirement-based design as well as reducing material cost and build time," adds Bastech engineering manager Scott Young. "This type of expertise is built within the Cimatron software, which enables our designers to think about design without worrying about navigating through the CAD package to define complex internal channels."

Time and Cycle Savings

The Bastech design for the first benchmark was a tapered helix positioned on the inside of a spacing cone used for industrial assemblies. It created conformal cooling channels by rotating a teardrop configuration so that one side was parallel to the outer surface of the core while maintaining a constant distance from it. By running the cross-section along a tapered helix, Bastech designed geometry that the ProX DMP 200 could build in a single run.

The mold design took two days and was 3D printed on the ProX DMP 200 in three days. To maximize its productivity, Bastech combined the 3D print run for the mold with parts required for other Bastech projects.

The ProX DMP 200 is a cost-effective alternative to traditional manufacturing processes, offering reduced waste, greater speeds for production, short setup times, very dense metal parts, and the ability to produce complex assemblies as a single part.

"It's a tool that enhances our capabilities on the molding side," says Staub. "It gives us higher turnaround tooling and solves bottleneck problems in the shop. We can save 30-40 hours per mold by eliminating EDM and drilling and drastically reducing CNC and polishing work."

For the reverse-flow helix core, the design and analysis in Cimatron software combined with 3D printing on the ProX DMP 200 saved more than 40 hours of programming and shop time. When all costs were taken into consideration, the 3D-printed core yielded a net savings of US$1,765 (18 percent) over conventional methods, according to Young.

More importantly, the conformal cooling mold maintained a lower temperature throughout the run and reduced cycle time by 22 percent.

"Cycle time is nearly everything in injection molding, with the ability to consistently control temperature a close second," says Staub.

"The more consistently we can hold temperature, the more consistently we can mold quality parts," says Young. "Eliminating warping due to temperature variation and lowering cycle time represent huge performance gains."

Savings Beyond the Core

In a second benchmark, Bastech went beyond the conformal core to design a complete core, cavity, and slide-mold set for 3D printing. In this case, the goal was to maintain the same temperature (110F) between the conventional and conformal designs to see how it would affect cooling and cycle time results.

Once again, Bastech recorded major time savings for programming, machining, and polishing, and completely eliminated EDM in the conformal cooling design. Automation within Cimatron software reduced design time from 30 hours to just seven for the conformal cooling mold. Total cost savings for the 3D-printed mold was US$2,505, a 16 percent savings.

Cooling time was reduced from 10.5 seconds for the conventional mold to 7.5 seconds for the conformal mold, and the all-important cycle time was reduced by 14 percent.

"Even though the temperature remained the same for both the conventional and the conformal cooling designs, the conformal design forced more liquid through a greater surface area, making it more efficient in cooling the mold," says Young.

Major Bottom-Line Impact

"The desire for better cooling techniques has been hanging out there for a long, long time," says Young. "We now have the software to help mold makers make better decisions about how to set up their cavities, cores, and inserts, then bring them into reality with direct metal 3D printing."

"With traditional cooling for injection molding, there is no perfect situation," says Staub. "You can only drill holes in certain places, and you can't curve holes around channels like you can with conformal cooling designed for 3D printing. Now we no longer have to accept compromises in conformal cooling designs."

Bastech purchased the ProX DMP 200 printer through a grant from the state of Ohio and the University of Dayton Research Institute, so part of its mission is to share results with the industrial community. Staub hopes that the Bastech benchmark efforts will show shops of all sizes that there are solid, end-to-end solutions available to achieve conformal cooling.

"A lot of toolmakers will need to adopt these 3D technologies to improve their shops," he says. "We want to share our successes so other shops can see that it not only can be done, but it can be done in a way that has a major impact on your bottom line."