"The 3D printing process shaved upwards of six weeks off the process, since the encapsulation rubber can now be done in line with the actual machine assembly. We also eliminated the risk of material-handling damage to the completed assembly."

For many industries throughout the world, 3D printing has become the go-to technology for rapid prototyping of parts and assemblies. But despite success in automotive racing, custom medical devices and other industries, when it comes to 3D printing of production molds and machined parts the attitude of many engineers can be summed up in two words: "Prove it."

That was certainly the case for Carol Connors, a mechanical designer and document control manager at Cooper Environmental Services in Beaverton, Oregon.

Connors has relied on Quickparts, the 3D Systems' On Demand Manufacturing service, to deliver rapid turnaround on 3D-printed prototypes. Quickparts provides instant online quotes for custom parts, expertise in the 3D design-to-manufacturing process, and proven manufacturing services support.

What Connors didn't know was whether Quickparts could meet her needs for a production-quality mold.

"I knew that not all 3D-printing powders and liquids have the same material characteristics as their conventional counterparts," Connors says. "So, I wanted to be able to test a range of materials in the actual environment in which the mold would be used."

Can it handle the heat?

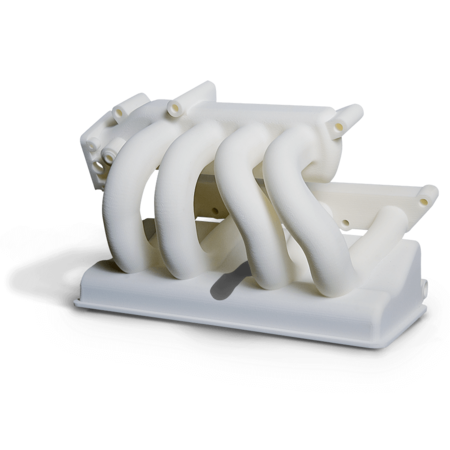

Her first test case was to see if Quickparts could reduce the months-long turnaround time needed to create a mold for a fitted vulcanized rubber shell. The shell covers an assembly that transfers heat in a continuous emissions monitoring system. The system is placed in industrial energy gas stacks worldwide to monitor metal pollutants.

"Typically we'd wait as long as three to four months until the actual assembly was built, then ship the by-now very expensive, one-off assembly to the manufacturer, who would use the actual part as a mold to shape the rubber," says Connors. "Finally, all of this would go into a vulcanizing oven under vacuum to create the part."

Connors contacted Quickparts, which sent her material data sheets and a sample box of the material grouping she was considering. She sent the materials to her vendor to test several of the selected samples. The samples were subjected to 325°F @ 1.5~2.0 Atmospheres for approximately three hours in the oven used to create production parts.

"We tested the samples by putting them through the same process as any other mold to prove the material would stand up to the heat and beating it would take when used as a mold," says Connors.

The winning material from the testing was 3D Systems' DuraForm PA Plastic, known for producing durable and repeatable molds and end-use parts. DuraForm PA is exclusive to 3D Systems' family of industrial-grade selective laser sintering (SLS) 3D printers.

For this project, Connors and Quickparts decided on 3D Systems’ sPro 60 HD SLS 3D printer. The sPro 60 HD produces true thermoplastics with high accuracy and smooth surface finishes for everything from industrial designs to medical devices to ducting components.

Connors used her CAD system to transform a 3D model of the assembly that the rubber shell covers into a single, simplified component for the mold model. She then digitally shelled the unified model to save material and so it would drain the uncured SLS material when printed. She determined the wall thickness of the shell by calculating the loading on the mold as the material inside approaches heat-deflection—the temperature at which polymer or plastic begins to deform in the mold.

The final 3D mold model was output as an STL file, and Connors and Quickparts collaborated to determine the best orientation of the platen for the 3D printing and the required surface finishing.

Shaving weeks off the process

"We were consequently able to deliver a new prototype machine to our majority share-holding partner on time," says Connor. "The 3D printing process shaved upwards of six weeks off the process, since the encapsulation rubber can now be done in line with the actual machine assembly. We also eliminated the risk of material-handling damage to the completed assembly."

Time and cost savings go well beyond the one-time fabrication of the mold, according to Connors.

"Before 3D printing of the production mold, we had to send a technician from the factory to the customer site to pull the part off the machine and ship the part to our vendor to make the new encapsulated shell," she says. "This in turn would be shipped back to the factory and then sent with the technician back into the field for installation and reassembly of the machine."

In the best of circumstances, this is a time-consuming and costly process. In the case of the vulcanized rubber shell, the traditional process would have been exacerbated by the fact that the machine needing the replacement part was in China.

"We saved—and continue to save—enormous amounts of downtime, travel expense and wasted time," says Connors.

Now that the mold is in the hands of Connors' vendor, new or replacement shells can be manufactured quickly on demand. It's easy for the customer to replace the part, as there is no need to disassemble and reassemble the continuous emissions monitoring system.

If the rubber shell mold degrades or wears out, Quickparts can use the digital file to 3D-print a new mold within a day or so. The digital process is applicable to other parts as well, saving Cooper Environmental weeks of turnaround time each time a replacement part is required.

New technology, old-fashioned values

With the strength and durability of 3D Systems' processes and materials proven in real-world conditions, Connors is now using Quickparts not only for 3D prototypes and production molds but for machined parts as well. Beyond its 3D design-to-manufacturing expertise, Connors gives Quickparts credit for something that never grows old: service. (Left: The finished vulcanized rubber shell manufactured with a mold produced using a 3D Systems sPro 60 SLS System.)

"It all went beautifully and smoothly. Quickparts was quick in responding, eager to help, and they worked with me. They weren't out to make a sale. Now they have a customer who will look their way first."