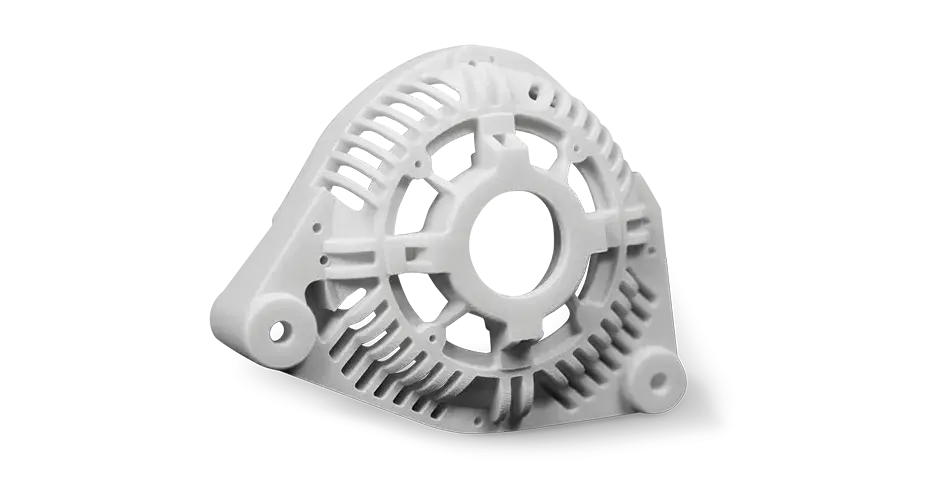

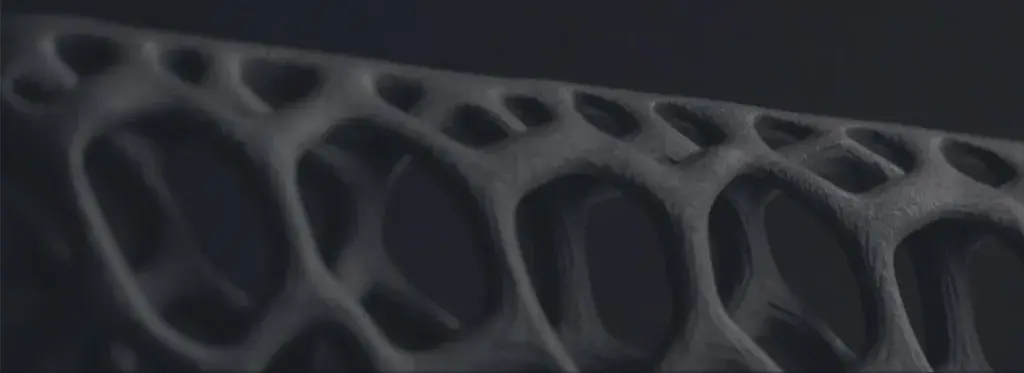

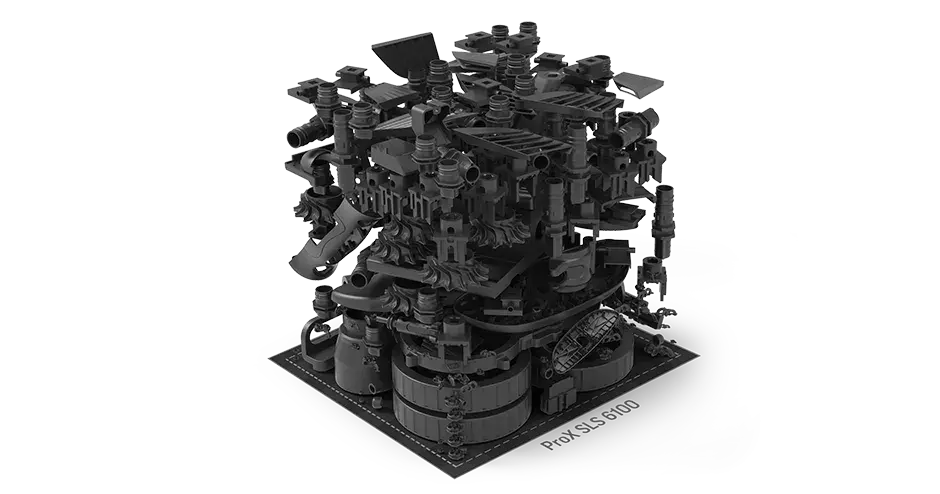

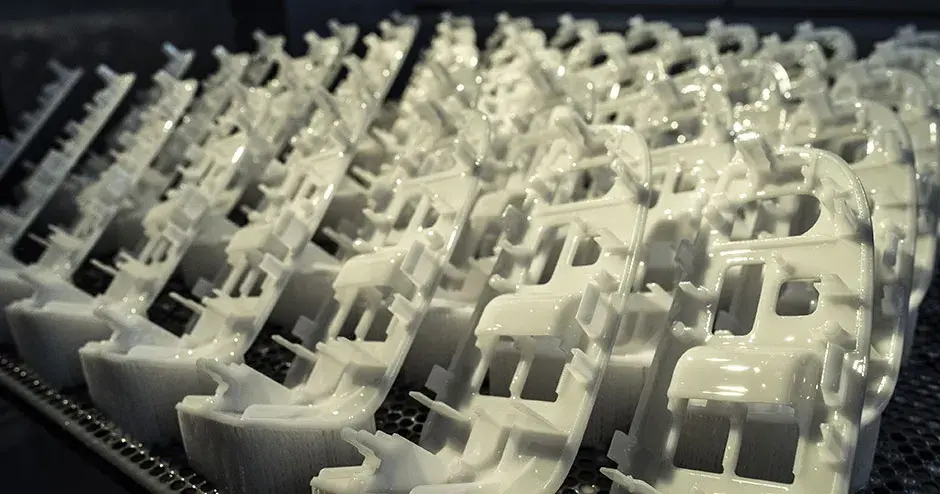

One of the major benefits of SLS is that it is a self-supporting additive manufacturing technology. Because the product lies in a bed of powder as it builds, no supplementary support structures are required, making SLS capable of producing geometries that no other technology can. The self-supporting nature of SLS also means there is no support removal, enabling complex interior components and monolithic assemblies.

SLS really shines when you need durable plastic parts. SLS parts are known for their robustness, and rival parts produced using traditional manufacturing methods like injection molding. SLS is used in a variety of end-use applications in industries including automotive and aerospace.

Considering its robustness and capability to produce highly complex parts, SLS can introduce major time and cost savings for small-run parts that would otherwise require assembly with traditional manufacturing. SLS is a perfect marriage of functionality, strength, and complexity. Because there is no expensive and inefficient tooling or retooling to worry about, SLS is particularly effective for mass customization for certain low-volume end-use parts. And due to the tendency of SLS parts to stand up against wear and environmental conditions, this technology makes it possible to produce fewer parts. As with other additive manufacturing technologies, SLS allows parts and molds to be stored digitally, using data that will never corrode, get lost in transportation, or require expensive storage. The designs are always available and ready to be produced as needed, even if the original part is unavailable.