The high school students from the ATC in Rock Hill have completed the next phase of their “Build-A-Car” project.

A month ago, we reported that the students were using scale models to verify form, fit, and function.

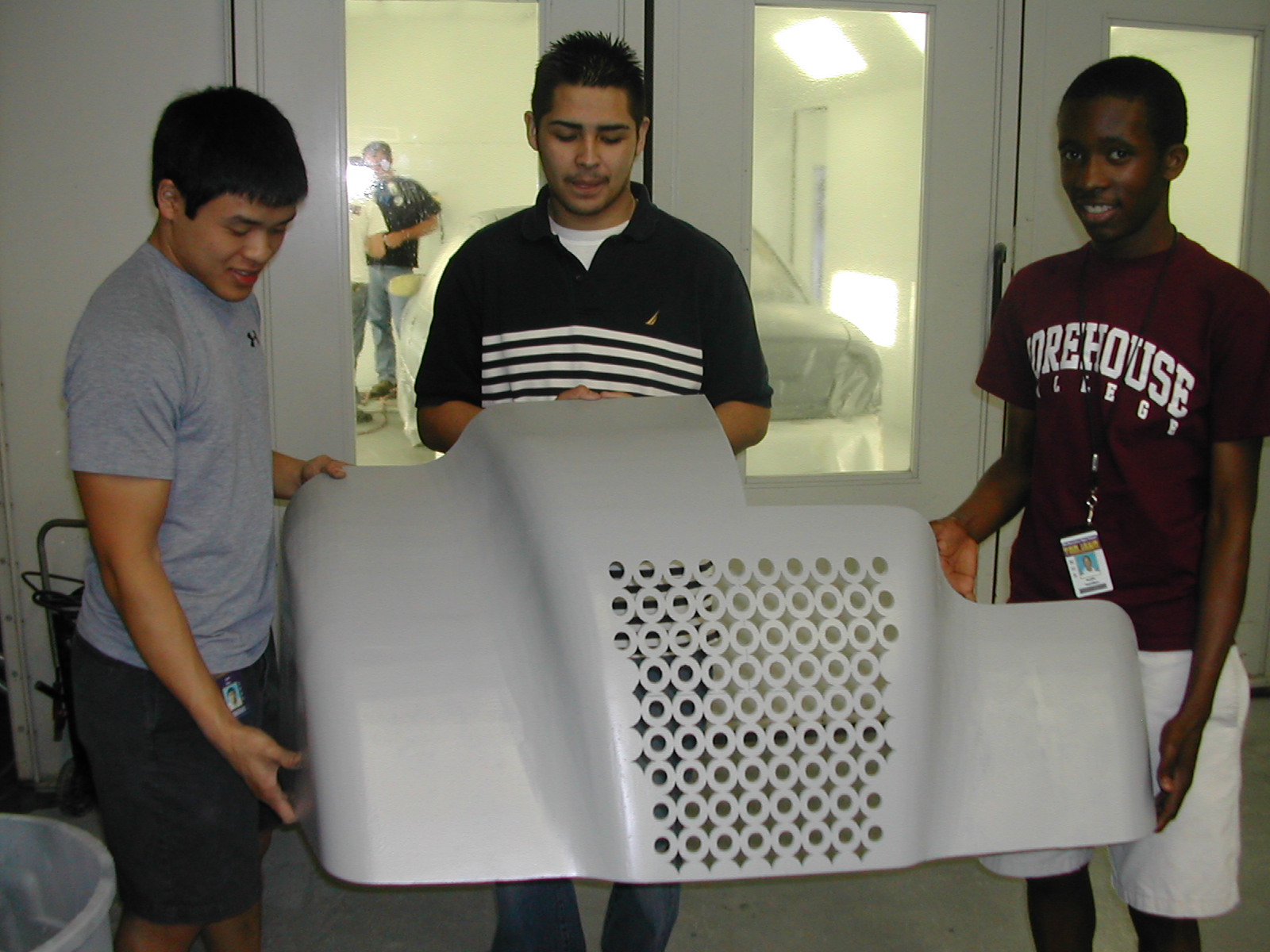

The final design was determined and the process of producing the body panels on the Sinterstation® Pro began.

Due to the size of the final product, the students used 3D Systems’ proprietary software to cut the car body into approximately 40 sections! After building each section, the parts receive their first primer coat in the Paint Booth, and the students assemble the parts onto the car.

We’ll keep you posted!

Read ATC “Build-A-Car” Project: Part 1 and ATC “Build-A-Car” Project: Part 2.

ATC students holding the car’s partially assembled front clip.