Written by Richard Sandham

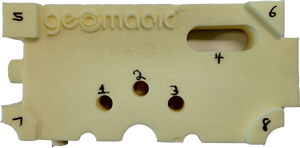

This past Summer, Geomagic set out to create our first ever demo part. This four part blog series is about our journey from the first edition to the final product starting with the initial design and ending with manufacturing...(skip to Part Two)

Born and raised in what was rural California I never thought I would have any reason to leave, let alone move my family to the opposite coast. But here I am...working on the bleeding edge of computing technology in Research Triangle Park, North Carolina...Californi-who?

I have been in manufacturing and metrology for thirty years and occasionally reach back and pull from that experience; no matter how hard I try to leave it behind. Actually it's why Geomagic hired me. Working for Ping and the amazing brain trust here at Geomagic has simply been a joy. Don't get me wrong here, Ping is the first CEO I have had the pleasure to work for that does not need my job "explained" in any way. It is in fact quite the contrary. Blathering aside...when they asked me to step out of my current role and help finish our new demo part for Sales and Marketing I jumped at the chance. The design was 95% complete, but schedule and cost had crept up and the project was forced to take a turn towards my bread and butter: Injection molding. I was confident that I could knock it out of the park. Confident I could perform for once at equal pace to that of everyone here in the US and abroad that keeps Geomagic in the lead.

It was a true fire drill. The Road Show and v2012 release were just weeks away and on the table was a deliverable reminiscent of the toy industry the impossible. Just over a month prior to v2012 release, a physical demo part and a thumb drive with the CAD model were to be delivered to every sales team member, partner, and on a first come first serve basis, every attendee of interest during shows, worldwide in a nice custom fit box. We didn't have a chance.

Enter Tom Simon, our Marketing work horse and whipping boy, under Rachael's flesh-removing gaze he ran the show, took the brunt of the stress, and relied on me to tell him what he wanted to hear. No issues, on time, under budget. I had nothing. We needed help on execution, it had to be right the first time, and it needed to be now and we found it online, in Minnesota. Tom gave me the contact information for the team at Proto Labs.

Jumping to today, Proto Labs, single handedly, has resurrected my belief in American manufacturing something I thought corporate America had outsourced long ago. It's not dead, it has a pulse, and remains viable in a few proud groups of manufacturers here in the US Proto Labs is one of them.

Stay tuned as we walk through the process of taking intent to deliverable parts in ten days...and reverse engineer and inspect those parts in less than one.