We bring our products to market to help engineers and designers overcome challenges, so every now and then we like to put them to the test to self-check. For this year’s RAPID Conference in Long Beach, we decided to do just that and gave ourselves two weeks to rebuild a broken motorcycle component using 3DS scanning, engineering and manufacturing software, along with our 3D printers.

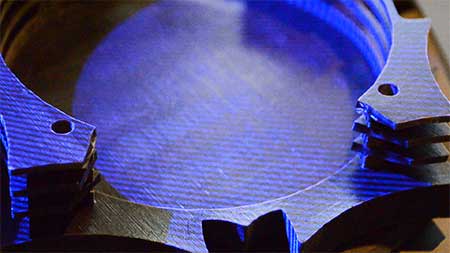

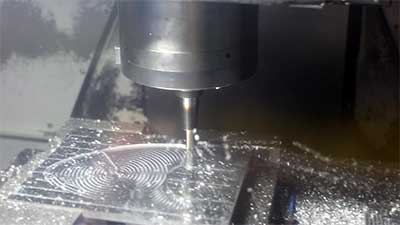

Demonstrating our full ecosystem of scan-design-manufacture software, we began the rebuilding process by taking a quick 3D scan of the original clean air motorcycle filter using Geomagic Capture. We then reverse engineered the data in Geomagic Design X before starting the machine programming of the back plate in GibbsCAM and the 3D printing of the front plate on the ProJet 6000 SLA 3D printer. We produced the machined part at Quickparts’ Tulsa-based APproto facility.

Following all this, we went one step further to make new designs with the help of artist, inventor and TV personality Scotty Ziegler. We had Scotty’s designs machined at Quickparts, and will be 3D printing them before (and during) the show using GibbsCAM and Geomagic software. These are truly things you’ll have to see to believe, so come to RAPID 2015, booth 814, and check them out.

Following all this, we went one step further to make new designs with the help of artist, inventor and TV personality Scotty Ziegler. We had Scotty’s designs machined at Quickparts, and will be 3D printing them before (and during) the show using GibbsCAM and Geomagic software. These are truly things you’ll have to see to believe, so come to RAPID 2015, booth 814, and check them out.

At the event, you’ll be able to experience 3D Systems’ Digital Thread: accurate 3D scanning of parts, rebuilding them rapidly in Geomagic software, choosing to machine parts or build tools using GibbsCAM and CimatronE software, and 3D printing other parts.

You’ll also see many of our 3D printers on display, including the ProJet 5500X multi-material 3D printer, industry-leading SLA printers, full-color plastic with the ProJet 4500, and metal 3D printing with the ProX 200.

You’ll also see many of our 3D printers on display, including the ProJet 5500X multi-material 3D printer, industry-leading SLA printers, full-color plastic with the ProJet 4500, and metal 3D printing with the ProX 200.

Whether your interest is hardware or software, we have the industry-leading solutions for you. So come see us at RAPID, May 18-21st , booth 814 at the Long Beach Convention Center, in Long Beach, CA.

Images from top to bottom: Scanning the broken part with the Geomagic Capture blue light scanner; SLA 3D printing of a new part; Machining using GibbsCAM software programming at a Quickparts facility.