June 2006

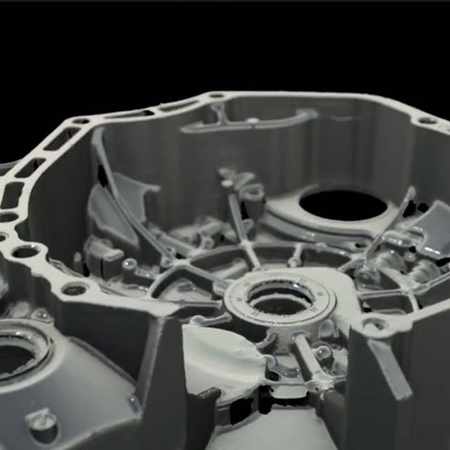

The Royal Australian Air Force (RAAF) operates 71 FA-18s from a number of bases throughout Australia. As part of on-going maintenance, these aircraft are inspected for cracking of structural components in the wings, and damaged aircraft are grounded until repairs are made. The standard repair for these cracks is a stainless steel doubler fitting that is riveted into place, bridging the crack.

The traditional repair process required that an impression of the area be made using dental putty. Then the machinists in the 381 Expeditionary Combat Support Squadron – Mechanical Engineering Operations Management Section (381 ECSS -MEOMS) of the RAAF would measure the mold with calipers and create a 3D CAD model that was exported to computerized numerical control (CNC) milling machines.

The fit tolerance required for the doubler fitting is within 0.25mm (0.010 inches). The machinists were able to achieve these results, but it was taking up to six weeks, and the process resulted in multiple rejected samples. This led to the grounding of several aircraft for extended periods of time.

The RAAF contacted engineering firm Wysiwyg 3D Pty Ltd to help streamline the process. Wysiwyg’s solution included a Platinum seven-axis FARO arm and scanner, and Geomagic Design X and Geomagic Control reverse engineering and 3D inspection software.

Now the repair procedure takes only two to three days.

“The RAAF needed a solution that was both portable and highly accurate,” says Shane Rolton, managing director of Wysiwyg 3D Pty Ltd. “These tools provide the RAAF with great flexibility to support whatever job it needs to do in-house or in the field.”

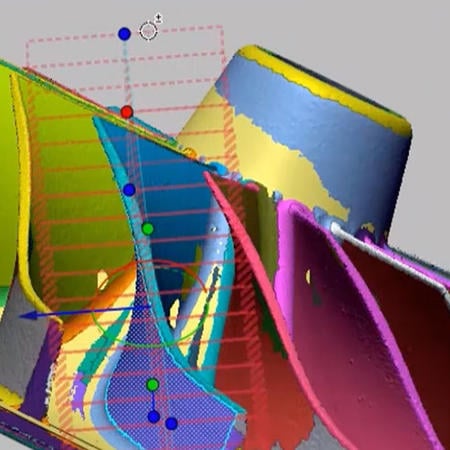

The modified process still involves structural engineers making a mold of the damaged section with dental putty. The mold is then shipped to a regional machine shop and scanned using the FARO scanner. The scanner interfaces directly with Geomagic Design X, so scan results are immediately visible on-screen. Scanning time is less than five minutes.

Machinists then process the data in Geomagic Design X, which cleans up the scan data and automatically generates an accurate NURBS surface.

The IGES model from Geomagic Design X is exported to Mastercam V10 machining software, where a standard bracket design is adapted to reflect the scanned model geometry and numerical control (NC) codes are generated to machine the bracket as the first-fit sample in aluminum. The turnaround time from the dental mold entering the machine shop to the first-fit sample is less than 24 hours.

“Geomagic Design X is a great match for our mechanical approach,” says Corporal Greg Gannaway, a machinist with the 381 ECSS-MEOMS. “Our brackets contain flat planes, joggles and intersecting radii, and the software’s workflow results in fast surfacing and even faster modifications in Mastercam.”

Before the bracket is delivered for a trial fit, it is scanned with the FARO arm and scanner, and compared to the scan of the original mold in Geomagic Control. Within Geomagic Control, the aluminum part is inspected for fit with the mold scan data, and a 3D comparison report is generated, graphically highlighting matches and differences between the scanned data and the machined part.

Any parts that are out of tolerance are adjusted within the Mastercam software based on the values from the Geomagic Control inspection report and retooled. If the aluminum bracket meets the tolerances, the MEOMS machinists create a final stainless steel part using the same CAD model. This bracket is then riveted onto the plane.

“We’ve had great success with the new process,” says Rolton. “Eventually the RAAF machinists want to scan the aircraft itself, eliminating the need for the dental putty mold and increasing the on-location capabilities.”

With the portability of the FARO system, the speed of Geomagic Design X, and the inspection reporting of Geomagic Control, the machinists of the MEOMS section will one day make repairs in even less time and with more accuracy, ensuring that the Australian Aircraft Fleet spends minimum time on the ground.