3D Systems collaborates with Thales Alenia Space in the field of design for additive manufacturing (DfAM) to improve performance of a critical sub-system on its Spacebus NEO satellite. The resultant Electrical THruster Mechanism (ETHM) is comprised of seven different additively manufactured brackets. Additive manufacturing (AM) enabled the mechanism to be packaged within a limited volume at the lowest possible mass. Experts within 3D Systems’ Application Innovation Group contributed design and manufacturing know-how to Thales Alenia Space’s ETHM project, packaging their expertise within the final build files that were transferred to Thales’ AM production facility in Morocco. This expert-generated manufacturing plan enabled Thales to seamlessly transition production to its own additive manufacturing facility which is outfitted with several 3D Systems’ direct metal printers.

“Every feature is more or less conventional, but putting them together in a single compact and competitive mechanism is really a challenge.”

- Gilles Lubrano, ETHM Product Manager

The Challenge

OPTIMIZE CRITICAL SATELLITE SUB-SYSTEM FOR ACCURACY AND RELIABILITY

The Electrical THruster mechanism points the satellite propulsion of the Spacebus NEO satellite to correctly position it in space. As such, the reliability of this component is mission-critical. Four ETHMs are required per satellite, forming the chassis around the engines. These parts perform as two axis gimbals holding the electrical propulsion unit, and enabling it to vector with smooth and steady movements.

To meet Thales Alenia Space requirements, the ETHM needed to balance volume and mass constraints while meeting stringent performance specifications, including:

- High angle pointing accuracy (0.1-degrees);

- Part count reduction including functional integration of various thruster commodities (harness and piping);

- Serial production that meets quality requirements for orbital class products.

The Solution

CONSULTATION AND COLLABORATION FOR SCALABLE PRODUCTION

01 Design for Additive Manufacturing Consultation

Thales Alenia Space and 3D Systems have an enduring collaborative partnership, and have worked together to put over 1,700 flightworthy parts in orbit as of 2021. In the ETHM project, Thales Alenia Space partnered with 3D Systems’ Application Innovation Group (AIG) to combine several functions within a small design space while guaranteeing accurate dynamics.

The total dynamic volume allotted for the ETHM is 480 mm x 480 mm x 380 mm, and includes rotary actuators, harness, tubing, and a holding mechanism. 3D Systems provided manufacturability and design feedback to help Thales Alenia Space achieve its performance objectives. 3D Systems experts helped Thales Alenia Space achieve an optimized strength-to-weight ratio while solving for areas of heat concentration to protect functional components from thermal damage.

By using AM to design and produce a system, Thales Alenia Space triggered an expansion of positive impacts. Light-weighting improved thrust efficiency beyond what conventional manufacturing would allow, which in turn improved fuel efficiency, resulting in lower costs and new opportunities for technical innovation elsewhere.

02 Manufacturing Flow Development

3D Systems helped Thales Alenia Space develop a robust manufacturing flow comprising post-processes like CNC-finishing and 100% tomography inspection to guarantee product and process repeatability in an AS9100 controlled environment. 3D Systems application engineers also provided guidance on the level and sequencing of quality controls for risk mitigation to help Thales Alenia Space ensure a thorough, quality-oriented, and cost-efficient manufacturing flow.

This expertise helped Thales Alenia Space achieve the 0.1-degree pointing accuracy required with an exacting CNC and inspection workflow in which some parts have as many as 249 measurement points taken via coordinate measuring machine that must be in spec. 3D Systems’ collaborative approach included education about the technology along the process of integrated quality controls, as well as root cause analyses of non-conformities against Thales Alenia Space specifications to ensure success. Prior to transitioning production to Thales Alenia Space, 3D Systems helped organize and coordinate a best-in-class supply chain to fulfill series production and produced more than 70 parts at its Customer Innovation Center in Belgium, which is part of 3D Systems’ AIG. The high capacity of this facility and repeatability across 3D Systems’ DMP machines helped ensure a short lead time.

03 Print File Preparation and Transfer

To ensure a seamless transition of ETHM production to Thales Alenia Space, 3D Systems application engineers developed each print file in 3DXpert®, incorporating years of AM expertise that saved Thales Alenia Space time and money while guaranteeing quality. Using these expert-generated build files, repeatable production is possible on any 3D Systems direct metal printer. The final brackets are printed in LaserForm Ti6Al4V grade 23 titanium material.

Several aspects of the thruster mechanism design made 3D Systems’ guidance on print strategy of particularly high value, including:

- Maintaining intended roundness of several open structures with large circular interfaces.

- Balancing support strength with removability.

- Accounting for thermal stresses during the printing process that vary based on the geometry and material printed.

3D Systems’ experience working with titanium materials has helped countless critical applications balance complexity and strength to achieve project parameters. Tools like 3D Systems’ 3DXpert simulation module help support these projects by reducing the number of iterations required to achieve a successful outcome.

04 Technology Transfer

Thales Alenia Space is now capable of printing these parts at its own facilities following the training and technology transfer 3D Systems has provided over the years. Thales’ group 3D factory in Morocco is outfitted with several 3D Systems’ DMP machines, and took advantage of 3D Systems’ technology transfer offering at the time of installation. Technology transfer is an in-depth, AM-specific training designed to help new printer customers accelerate their transition to AM and safeguard their investment. In combination with the pre-developed build files, 3D Systems has fully supported Thales in its transition to in-house production.

“Using the same machines as the ones in our Customer Innovation Center in Belgium, Thales has simplified its access to a successful print so its team can focus on the industrialization of AM and maximize its return on investments,” said Koen Huybrechts, Manager Application Development, Application Innovation Group, 3D Systems.

The Result

BALANCE OF KEY PERFORMANCE CRITERIA FOR OPTIMIZED, SYSTEM-LEVEL DESIGN

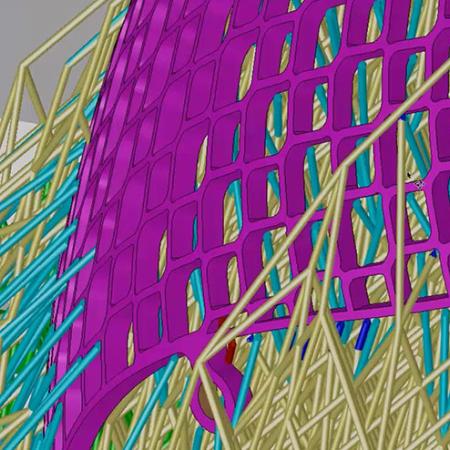

ETHM is one of the first full space mechanisms entirely designed with additive manufacturing in mind. The seven different topologically optimized brackets raised the standards of a multi-disciplinary team by their size, the required high precision, and system criticality.

- Pointing accuracy of 0.1-degrees ensures mechanism will perform as expected in flight

- Increased thruster efficiency from reduced weight of topologically optimized brackets

- 249 measurement points validated for quality control of most complex part

- Integration and protection of thruster commodities for optimal form and function

The Spacebus NEO is part of the European Space Agency’s 15-year Advanced Research in Telecommunications Systems (ARTES) Program.