CHALLENGE

Increase productivity of injection molding for an automotive duct that required a long tooling cycle to avoid warpage.

SOLUTION

- 3DXpert® metal AM software by 3D Systems

- Blue laser line 3D scanner

- Cimatron® integrated CAD/CAM software by 3D Systems

- Geomagic® Control X™ inspection and metrology software by 3D Systems

- LaserForm® maraging steel material by 3D Systems

- Moldex3D® plastic injection molding simulation software

- ProX® DMP 300 metal 3D printer by 3D Systems

RESULTS

- Accelerated cycle cooling time from one minute to 40 seconds.

- Increased duct production rate by 30%.

- Reduced temperature variation across cooling by 86%.

- Extended mold lifetime from reduced molding pressure.

- Produced parts that consistently meet tough quality requirements.

- Delivered higher-quality parts with more efficient cooling, which enabled time and cost savings for tool builders and mold operators.

Large temperature variations in an injection-molding cooling cycle can dramatically increase the risk of parts warping. When tests of a conventionally-designed and manufactured injection-molded automotive duct yielded temperature fluctuations of 132˚C throughout the process, B&J Specialty, Inc. recommended conformally-cooled mold inserts to its client for more even cooling.

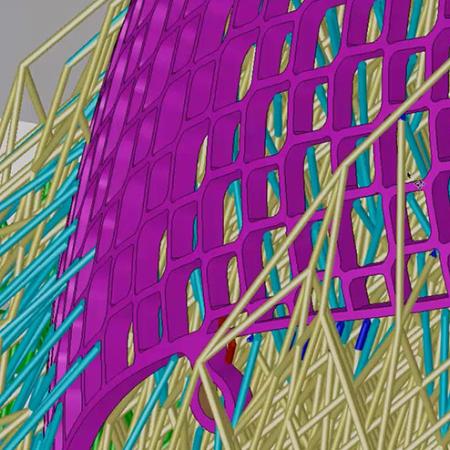

To achieve this, B&J Specialty engineers relied on Cimatron CAD/CAM software to design the molds and conform the internal cooling channels parallel to the part’s surface. To deliver these complex internal conformal cooling channels accurately, they used metal additive manufacturing (AM) on a ProX DMP 300 printer for production.

The new conformally-cooled mold insert reduced temperature variation throughout cooling to 18˚C and shrank cycle time on the mold from one minute to 40 seconds, an overall productivity improvement of 30 percent.

Sub-Optimal Cooling Lines Lead to High-Temperature Variations

Conformally-cooled molds take advantage of modern technology to solve an age-old problem. Many injection-molded parts have curved surfaces, yet the drills used to create cooling channels only produce straight lines. In most cases, this means it is impossible to match cooling lines to part geometry. Conventionally-produced straight cooling lines have to run beyond the outermost features of the part to avoid interfering with the cavity, which means that features closer to the part’s center are typically far from the nearest cooling line. This often results in significant temperature variations over the volume of the part at the start of the cooling process.

The automotive duct that B&J Specialty redesigned for more-efficient cooling features multiple irregular and curved surfaces. In the original mold design, B&J drilled straight cooling lines through a hub and stator block that were used to adjust the mold geometry to account for warpage. As is often the case with irregular shapes, several key features of the duct were distanced from the cooling lines due to the limitation of the straight channels. The resulting temperature variations generated various residual stresses that tended to bend the part as it cooled. In the past, this problem was addressed by extending the cooling cycle to ensure the part was fully solidified before removing it from the mold and adjusting the inserts to account for any remaining warpage. The problem with this approach was that lengthening the cooling cycle reduced productivity and increased the cost of making the part.

Updating the Mold with Conformal Cooling Channels

According to B&J Specialty information technology and 3D printing manager Jarod Rauch, the automotive duct appeared to be a strong candidate for a modified conformal cooling design, which would help to improve final part quality, reduce scrap, and shrink the cooling cycle. B&J Specialty proposed this solution to their client, an automotive supplier, who agreed to test the new methodology. Provided with the CAD file of the original geometry, B&J engineers got to work using Cimatron mold design software. “Cimatron is pretty much a one-stop-shop software that allows us to have full CAD functionality for designing and gives us the option to roll right to build preparation from the same package.”

Rauch says B&J Specialty discovered Cimatron while researching metal 3D printers for conformal cooling applications. “We saw that 3D Systems provides a complete end-to-end solution including mold design software, build preparation software, and 3D printers, which got me excited about this solution,” says Rauch. “3D Systems not only focuses on the machine, but it also focuses on how engineers design for additive.”

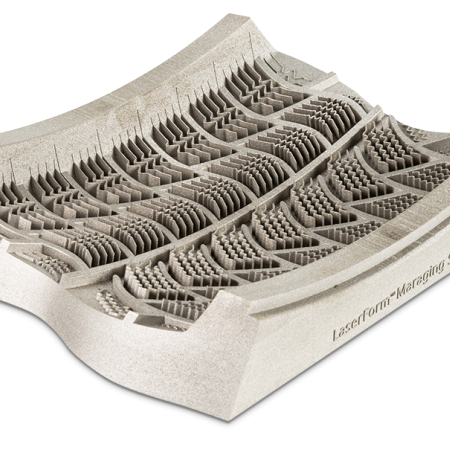

Working within Cimatron, B&J engineers removed the original straight cooling lines and replaced them with conformal ones that maintained a consistent distance from the part’s surface. Final mold production with metal 3D printing allowed the engineers to design complex channels with improved cross-sections and interface surfaces. These features help ensure turbulent flow, which further increases the amount of heat transferred from the mold to the coolant to assist with efficient cooling. The ability to cool molded parts more efficiently also helps ensure part quality by reducing the occurrence of part defects such as warping and sink marks. A direct path to higher-quality parts saves time and money for both the tool builder and the mold operator by limiting the number of corrections, trials, and sampling required to achieve the desired results.

Setting Expectations with Accurate Simulation

B&J engineers then exported the mold file from Cimatron to Moldex3D injection-molding simulation software for integrated cooling simulation. “The integration between Cimatron and Moldex3D makes it easy to simulate the complete injection-molding cycle, map temperatures across the mold and part to identify hot and cold spots, and simulate the effect of different cooling times,” says Rauch. The simulation also helps highlight areas where redesign may improve the overall cooling strategy before they make any investment in a physical part. Comparative simulations between the original mold design and the new design with conformal cooling lines showed a dramatic improvement in temperature distribution for the new part, reducing temperature variation by 86 percent.

3D Printing Mold Inserts with Conformal Cooling Lines

B&J engineers then used 3DXpert metal AM software to prepare the mold insert designs for production. They imported the part data, optimized the geometry, calculated the scan-path, arranged the build platform, and sent the job to their in-house ProX DMP 300 metal 3D printer directly from the 3DXpert software.

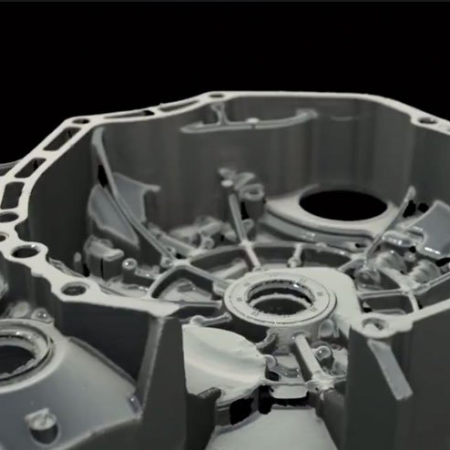

The ProX DMP 300 directs a high-precision laser to build up metal powder particles selectively in thin, horizontal layers, one after the other using LaserForm material. For this automotive duct mold, B&J Specialty used maraging steel material. “The ProX DMP 300 is ideal for producing conformal cooling lines because of its extraordinary accuracy,” Rauch said. “We can hold tolerances of three- or four-thousandths of an inch.” The 3D Systems patented direct metal printing (DMP) technology enables smaller material particles to generate the finest feature detail and thinnest wall thicknesses. A surface finish quality of up to 5 Ra μm (200 Ra micro-inches) is achievable and requires less post-processing.

Substantial Gains in Productivity

After 3D printing, B&J Specialty scanned the inserts into Geomagic Control X inspection and metrology software using a blue laser line 3D scanner and overlaid the mesh on the as-designed geometry to validate the metal 3D-printed mold inserts. The inserts were shipped to the automotive supplier who installed them on its molding machine. “Benchmark testing demonstrated that the more even cooling provided by the conformal lines made it possible to reduce the cycle time and increase productivity throughput by 30 percent,” Rauch said. “We also expect the life of the mold to be substantially higher since the cycle time reductions provided by conformal cooling make it possible to reduce the injection pressure, which in turn reduces wear on the parting line and intricate details of the mold.”