They call it stock car racing, but it’s anything but stock. By the time a NASCAR racing car hits the track, only the outline of the car’s body conforms to the corresponding model on the showroom floor.

Some of the biggest changes are reserved for the engine. For teams such as Richard Childress Racing - home of Winston Cup drivers Kevin Harvick, Jeff Green and Robby Gordon - the challenge is to take the basic SB2 General Motors engine and squeeze out the most horsepower and torque possible within NASCAR rules.

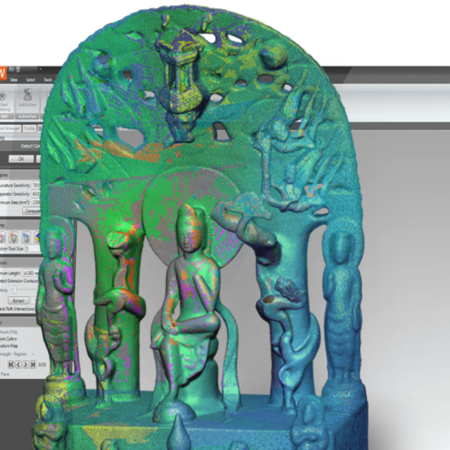

One of the newest tools available to GM racing teams is an accurate 3D model of the SB2 engine block, created by Richard Childress Racing (RCR) using Geomagic Wrap software from 3D Systems and Parametric Technology Corp’s Pro/ENGINEER.

The new SB2 model enables GM and its racing teams to conduct finite element analysis (FEA) and computational fluid dynamics (CFD) studies based on an accurate digital replica of the cast part. It also provides the foundation for creating a complete digital engine assembly.

SB2 - Foundation for Horsepower

The SB2 - short for Small Block, Second Generation - is the first engine designed by General Motors specifically for NASCAR racing. It simplifies preparation for racing teams and reduces the overall cost of building and maintaining an engine. The SB2 was presented to NASCAR officials in late 1995 and won approval for Winston Cup competition before the 1998 racing season. It is the basic engine behind some of NASCAR’s legendary drivers, including Jeff Gordon and the late Dale Earnhardt, a member of the RCR team for 20 years.

The original small-block V8 was introduced in 1955. Over the years, modifications for racing were made to the original block design to increase durability and to add features needed to work with each new cylinder head design. Since the original design dated back nearly 50 years, there was no 3D digital model of the block, only 2D prints.

For Winston Cup and Busch Series racing teams, the SB2 is just the starting point for building a competitive racing engine. NASCAR teams spend hundreds of thousands of dollars and tap into a treasure-trove of skill and imagination to reach peak performance of 800 horsepower for Winston Cup and 700 horsepower for Busch engines. In comparison, the original GM small-block engine produced 162 horsepower. The carburetors in SB2 engines deliver more than 800 cfm of air/fuel mixture and the engines get about four miles to the gallon.

Digital Model Challenges

Last year, GM’s racing division asked Richard Childress Racing to create the first 3D digital model of the SB2 engine block. RCR was a logical choice for the assignment. The team uses scanners and Geomagic Wrap software to reverse-engineer engine cylinder head ports for its cars. The process enables RCR to generate highly accurate ports in about one-sixth the time it took to do the work by hand.

Even with RCR’s experience, however, the SB2 project created a new set of challenges.

"The geometry of the casting - the shape, draft, water jackets and internal cores - is complex," says Clifton Kiziah, the senior design engineer who headed the project.

A logical starting point for a traditional reverse-engineering project would be the 2D drawings. In this case, however, the 2D prints don’t contain the whole story. When 3D molds and cores are constructed, changes are made that are not necessarily detailed in the 2D prints. RCR wanted to capture these details as they appear in the finished part.

Complicating matters further, the cast-feature shapes are difficult to reproduce using direct CAD geometry, even after precise measurement. Radius rounds from an actual casting, for example, might be spline-shaped, not spherical with a single radius as depicted in CAD models.

"We wanted a model of what we have, rather than an idealization of what we think we have," says Kiziah. "The 3D model needed to match the physical block as accurately as possible."

Accuracy for RCR requires casting tolerances of plus or minus .030 of an inch. Anything less might compromise the credibility of FEA and CFD testing results.

Removing Physical/Digital Boundaries

Meeting the project’s goals required software that would allow RCR to capture data from an actual SB2 engine block and turn it into a highly accurate 3D surface model. Essentially, the software needed to bridge the gap between the physical and digital worlds.

Geomagic Wrap fit the description and was being used successfully by RCR for the cylinder head porting project. But, that work was being done by another group within RCR, so Kiziah would have to learn Geomagic Wrap on his own.

Kiziah contacted Geomagic for advice on how to proceed with the project. Kiziah decided to take General Motors’ urethane molds of the internal cavities and send them along with an entire as-cast engine block to ADC, a Milwaukee-based scanning and reverse engineering company. ADC had experience scanning and generating digital models for complex parts from major manufacturers such as Fisher-Price Toys and Harley-Davidson.

ADC used an ATOS white-light scanner to capture the cores and engine block as eight separate point cloud files. The engine block was a 20 MB file and the cores were about 15 MB each.

ADC sent the point cloud files to Kiziah, who was beginning a two-day class to learn Geomagic Wrap. He used the class as on-the-job training, turning one of the point cloud files into his first 3D surface model.

Machining the Block in Software

The Geomagic Wrap reverse engineering process was automated and logical, according to Kiziah. After bringing the point cloud files into Geomagic Wrap, he did a uniform sampling operation to thin out the number of points. He then automatically created a polygon model and repaired data holes to make the model airtight. The polygon model was converted automatically to NURBS surfaces that were fine-tuned by Kiziah.

The eight surface files - complete with datum planes, axes and references created in Geomagic Studio - were imported individually into Pro/ENGINEER software. The cores were assembled in Pro/ENGINEER as they would be to cast an actual block. A cutout feature was used to subtract cores from the block.

"The critical datums created in Geomagic showed up in Pro/ENGINEER, where they were used as the foundation for the machining features on the block model," says Kiziah. "In effect, we were simulating in software how a block is physically machined."

Kiziah was able to achieve three times the accuracy required by casting, tightening the tolerance to .010 of an inch, and in some cases to within .005. And, although he was a novice with Geomagic software, he was able to complete the model much faster than if he had to model it from scratch.

"It would probably have taken several months if we had to model it directly, and I’m not sure we would have been able to capture the complexity of the actual cast surfaces," he says. "The finished model looks and measures the same as a real block."

Computerized Fine Tuning

Kiziah exported the final 90 MB model of the engine block from Pro/ENGINEER as an IGES surface, so it could be imported into GM’s CATIA software.

GM and its racing teams now have an accurate digital model of the SB2 engine block to use for engineering analysis. RCR is preparing to use the model to run CFD tests to optimize cooling, and secondary machining simulations to check for clearances and fit of new parts. FEA simulations will be used to determine where material can be removed in secondary machining without affecting the strength of the block.

"Without accurate geometry, CFD, FEA or secondary machining simulations cannot be performed effectively," says Kiziah. "When it comes to replicating cast parts, Geomagic Studio is the way to go."

The SB2 engine block could be just the start for RCR’s digital modeling. The team is working on a digital model of a total car assembly, complete with surface models of the chassis and the entire engine. At this rate, it might not be long before RCR is staging computer-generated races with exact digital replicas of its cars performing on virtual NASCAR tracks.