In 2009, Scott Summit was intrigued by a proposition that was put to him: while prosthetic limbs had come a long way forward in terms of mobility, comfort and improved materials, they still created a stigma for those using them. Could he find a way to make them more uniquely personal while keeping the process more affordable?

In partnership with an orthopedic surgeon, Dr. Kenneth Trauner, Scott, himself an industrial designer, started to research ways in which he could deliver a more customized experience to patients with prosthetic limbs. They founded Bespoke Innovations in San Francisco, CA, and research took him and Dr. Trauner to patients using the devices, and to new 3D software technologies and rapid prototyping devices.

Using Dr. Trauner’s medical expertise and Scott’s industrial design inspiration, they developed a fast, easy system that allows the rapid development of ‘fairings’ for prosthetic limbs that would deliver a higher degree of individuality for users. This process helps put individuality back into prosthetic legs. They add form, symmetry, and sculpture to otherwise lifeless mechanical components.

The process is currently targeted at below-the-knee amputees who have one sound-side leg. This allows a 3D scan of the intact leg to be matched for size and body mass. Bilateral amputees (people with two prosthetic legs) can be treated, although a substitute person of similar body mass and leg size would be needed for the 3D scan. In an hour-long consultation at the company’s location, which includes a couple of minutes needed for the 3D scan, the patient’s needs and desires for the fairings are established.

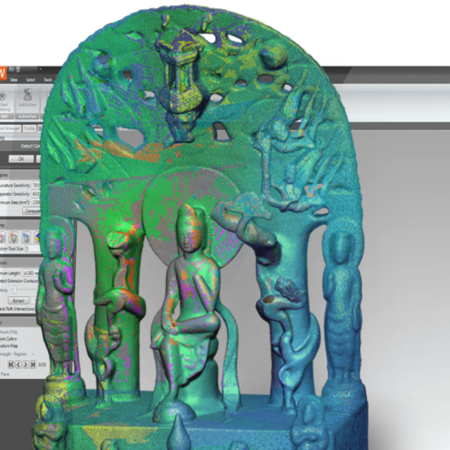

Using 3D scanning technology from 3D3 Solutions based in British Columbia, Canada, a scan of both the prosthetic leg and the good leg are taken. These 3D point clouds are loaded directly into Geomagic Wrap to be turned into usable 3D data. From there, changes to the 3D can be made in the Geomagic software and also exchanged directly into Autodesk Inventor for further customization.

‘Somewhere between the consultation, and getting the 3D data into Geomagic Studio, the magic begins,” says Scott. “The ideas of what the patient wants become real when they turn into 3D data.”

Using Autodesk Inventor 3D CAD software and Geomagic Wrap, the team at Bespoke Innovations can quickly create stunning and surprising fairings for prosthetic limbs that deliver a unique touch to each patient. Each fairing created is deliberately modular and designed to fit over the working mechanical parts of the prosthetic limb without interference. Materials used include nylon, leather, and metal, and a range of patterns can be used to increase the attractiveness of the fairings.

The fairing designs are then sent to the patient as a 3D image for editing and approval before it is manufactured using the company’s in-house rapid prototyping system for such things as metal-plating. The total process can take up to 3 weeks depending on changes made to the fairings prior to patient delivery.

“Each fairing is quite unique based on the patient’s needs, but our flexibility for custom design using a wide range of materials is very high, hard-wearing,” says Scott. “Some want practical fairings for daily use hard-wearing nylon. Some want an old tattoo matched onto a leather ‘skin’. Metal fairings that match a favorite motorcycle have a high level of attraction. We can handle just about every request.”

One example is a patient that wanted to wear cocktail-length dresses to evening concerts without attracting undue attention. The answer was to develop a fairing that resembled fish-net stockings, which could then be matched on the other leg. A favored tattoo on leather allowed another patient to rekindle his individual pride in body art.