The Statue of Liberty has stood over New York Harbor as a beacon of freedom for more than 120 years. But could she be rebuilt if damaged or destroyed? 3D reverse engineering software from Geomagic helps deliver an answer to that problem.

After the World Trade Center attacks, the value and vulnerability of U.S. national monuments are being given new consideration. And though there are numerous photos of Lady Liberty, there are no detailed architectural drawings that would enable an exact replica to be created.

Texas Tech University, the National Park Service, and the Historic American Buildings Survey (HABS) are working to change that. They are in the process of creating digital architectural drawings that will detail the statue’s every curve and dimension.

The university is finding success in capturing the statue’s unique architecture with 3D laser scanning technology and 3D Systems' Geomagic 3D point cloud software that automatically generates an accurate digital model from the scan data.

Massive Undertaking

Even under the best of circumstances, scanning an object that is 305-feet tall and weighs 225 tons would not be easy. Beyond mere size, the Statue of Liberty presented special challenges, according to Glenn Hill, director of Texas Tech College of Architecture’s environmental visualization program. The available space in which to do the scanning was limited in relation to the size of the statue. And the scanned model had to have a horizontal and vertical recording of 0.375 inches, which is the HABS standard for accuracy.

“The positions from which we could collect the data were very limited,” Hill says. “In addition to that, there were always crowds of tourists present, so there were security and safety concerns at all times.”

The team collected the data using a Cyrax 2500 3D laser scanner capable of capturing 800 points per second and tested at 6mm accuracy. Researchers spent four 14-hour days scanning different points around the statue. They then took the scanned data back to Texas and ordered a computer with dual 1.8-GHz processors, a 3-GB RDRAM video card, and two 80-GB SCSI hard drives to process and register the immense point-cloud data.

“We had 13 different scans with approximately 1.23 million data points per scan, a total of 16 million data points,” Hill says. “We tried to register these 13 scans together using targets placed in the scene, but we had a lot of difficulty getting appropriate alignment. We could not move forward unless we could register the point clouds, create polygon meshes, and finally generate NURBS surfaces to transfer to a CAD program.”

Putting the Pieces Together

The research team found the solution in Geomagic Wrap from 3D Systems. Geomagic Wrap takes scanned data and automatically generates highly accurate polygon and NURBS (surface) models.

The first step in Texas Tech’s process was to take the 16 million data points and align them into a polygonal surface.

“We viewed a variety of software programs and Geomagic was the only one able to register the huge number of data points that we had,” Hill says. “Trying to register the points without the software would have added at least 120 additional hours of work, and we would not have been able to achieve the adequate accuracy for the model.”

Another Challenge Ahead

With the polygon surfaces created, the next challenge for Hill’s team is to create a NURBS surface. Even though the team used a scanner specially made for large objects, it can only scan what’s in its line of sight. So any overlap or undercut on the statue wasn’t captured.

“Ideally we would scan it dead on or looking down on it,” Hill says. “The problem is that we were limited to scanning the statue from the ground in different pieces rather than the whole thing at once. This creates holes in the scan data. You have to eliminate all of the holes and imperfections in the model before creating a NURBS model to take into a CAD program for completion.”

Normally, holes and imperfections can be fixed automatically in Geomagic Wrap at an accuracy within .001 of an inch. But, because this is a historical record, John White, Director of Historic Preservation in the College of Architecture and Elizabeth Louden, Associate Dean of Research, must first document each hole that must be filled. The information then must be reviewed by HABS Chief Paul Dolinsky. The fills must also be recorded as part of the permanent documentation. If permission is not granted, Texas Tech will use Geomagic to surface the parts separately.

“We can surface large chunks individually and put them together piece-meal, but this will take weeks of work because we are dealing with hundreds of non-contiguous surfaces,” Hill says.

A Regenerated Lady Liberty

At the time of writing, the end goal of the project is still months away, but with new technologies such as those provided by Geomagic Wrap, the team has already saved weeks in production time.

“Undoubtedly there has been a lot of time saved,” Hill says. “Geomagic Wrap has helped us get closer to our goal of delivering a set of detailed 3D drawings of the statue to the Library of Congress and the National Park Service.”

The completion of the project will mark an important chapter in the statue’s history.

“When this project is finished, you will be able to take any portion of the statue and replicate it,” Hill says. “This is significant because it means the statue as a symbol of freedom will always be safe for future generations.”

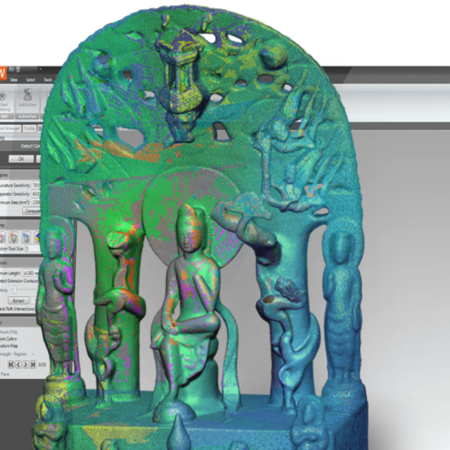

Texas Tech University used Geomagic Wrap software to generate a digital model of the Statue of Liberty from 16 million points of scan data. The holes are caused by overlaps and undercuts when the statue was scanned. Pending permission from the Historic American Buildings Survey (HABS), Texas Tech can use Geomagic to automatically fix holes in the data collection.