By the 3D Systems team.

The cool thing about many 3D Systems products is that with the right tools and some simple skills, you can easily create custom goods. Rather than just talking about it, though, we often conduct projects to prove these things out.

One project we have conducted for more than 3 years now is creating custom foosball players of our software team here in the 3D Systems Cary NC., office. This allows us to test out new versions of our affordable 3D scanning, software and CubePro printing.

For the release of the new generation Sense 3D scanner, we again decided to put our tools to the test for the Foosball table.

(above) We scanned Product Manager, Josh Kistner, with the new Sense scanner and a Surface Pro tablet.

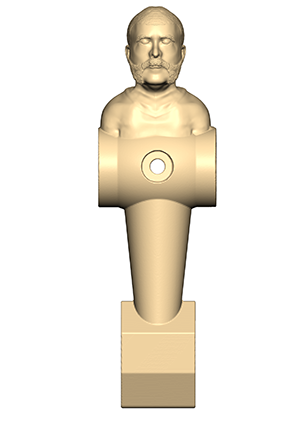

(Above) The completed scan was exported to Geomagic Sculpt to be smoothed and given definition that better resembles Josh’s features. The CAD data of the foosball piece was easily imported into Geomagic Sculpt and joined with the finished model of Josh.

Once modeling is complete, the data was prepped for 3D print and sent to the CubePro 3D printer.

(Above) 5 hours later, the piece was completed and ready to go onto the foosball table for some epic inter-office games.

By the 3D Systems team.

The cool thing about many 3D Systems products is that with the right tools and some simple skills, you can easily create custom goods. Rather than just talking about it, though, we often conduct projects to prove these things out.

One project we have conducted for more than 3 years now is creating custom foosball players of our software team here in the 3D Systems Cary NC., office. This allows us to test out new versions of our affordable 3D scanning, software and CubePro printing.

For the release of the new generation Sense 3D scanner, we again decided to put our tools to the test for the Foosball table.

(above) We scanned Product Manager, Josh Kistner, with the new Sense scanner and a Surface Pro tablet.

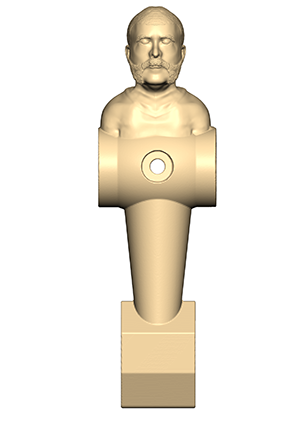

(Above) The completed scan was exported to Geomagic Sculpt to be smoothed and given definition that better resembles Josh’s features. The CAD data of the foosball piece was easily imported into Geomagic Sculpt and joined with the finished model of Josh.

Once modeling is complete, the data was prepped for 3D print and sent to the CubePro 3D printer.

(Above) 5 hours later, the piece was completed and ready to go onto the foosball table for some epic inter-office games.