US Certifications

ISO 9001: 2015

ITAR Registered

UK Certifications

ISO 9001: 2015

EN 9100:2018

UK AS9100

7.5mil

Parts produced per year

40,000+

Projects completed

75+

Material options

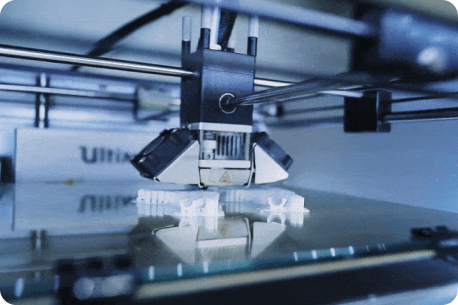

Functional Prototyping

When you need your prototype to be as close to the production model as possible, functional prototyping services is your best option.

But without a trusted production partner to take care of your functional prototyping with incredible accuracy backed by decades of experience, you won’t get the most out of your part.

Quickparts is equipped to handle all of your functional prototyping needs.

Our industry-leading experience and proven capabilities serve a wide variety of applications and industries. We are dedicated to delivering your part efficiently, accurately, and quickly, and our global network of facilities staffed with adept local engineers supports that mission.

Get Started

You’re seconds away from starting your Quickparts project.