US Certifications

ISO 9001: 2015

ITAR Registered

UK Certifications

ISO 9001: 2015

EN 9100:2018

UK AS9100

7.5mil

Parts produced per year

40,000+

Projects completed

75+

Material options

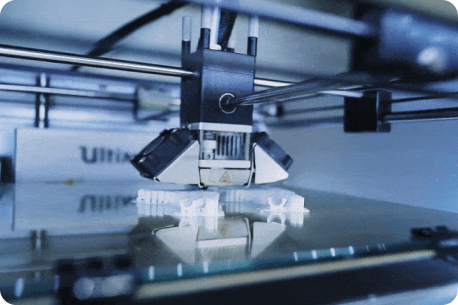

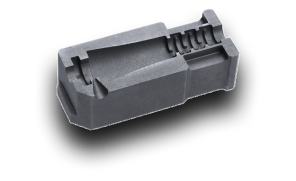

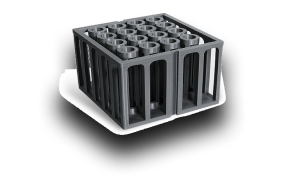

Low-Volume Production

Additive manufacturing and production-grade materials have made low-volume production easier to access.

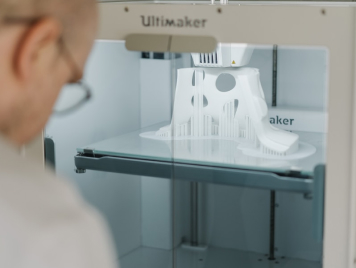

But choosing the right partner for your low-volume production projects is crucial when it comes to quickly and accurately receiving your parts.

Quickparts has the experienced engineers, dedicated project managers, and well-equipped facilities needed to handle your low-volume production.

Producing quality parts quickly isn’t just in our name—it’s a vision made possible by an exceptional team and advanced technology we’ve spent decades cultivating.

Get Started

You’re seconds away from starting your Quickparts project.