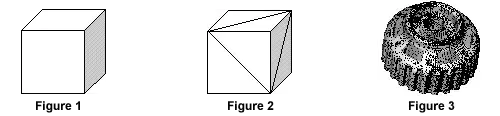

The STL file format has become the Rapid Prototyping industry's defacto standard data transmission format, and is the format required to interact with Quickparts. This format approximates the surfaces of a solid model with triangles. For a simple model such as the box shown in figure 1, its surfaces can be approximated with twelve triangles, as shown in figure 2. The more complex the surface, the more triangles produced, as shown in figure 3.

Almost all of today's CAD systems are capable of producing an STL file. For the user the process is often as simple as selecting File, Save As, and STL. Below are steps for producing high quality STL files from a number of today's leading CAD systems. In all cases, export your STL file as a Binary file. This saves on time and file size.

As a general rule, changing options such as Chord Tolerance or Angular Control will change the resolution on your STL file. The larger the STL file, the more triangles placed on the surface of the model. For simple geometry (not a lot of curves), the file may only be a couple hundred kilobytes. For complex models, files sizes in the range of 1-5MB will produce good parts. For many geometries, files larger then 5MB are unnecessary and will often just result in more time to get your quote and parts back.

Also, for most RP processes and materials, the minimum feature thickness is 0.020. Anything less then this and features will not develop. Please check your models and make appropriate changes to critical features. An exception is the High Resolution SLA, which will make features down to 0.010 and the SLS Flex material, which needs 0.040 thickness to produce features.

(Please note, these are only general guidelines and may not work or produce the best possible STL file in some cases. Please consult your users guide or the software's developers for more information or technical support. Should Quickparts determine that your STL file is not adequate for production, we will contact you for an updated file.)

AutoCAD

- Your design must be a three-dimensional solid object to output an STL file.

- Make sure the model is in positive space

- Set Facets to 10

- At the command prompt type STLOUT

- Select Objects

- Choose Y for Binary

- Choose Filename

CadKey / KeyCreator

- Choose Stereolithography from Export options

- Enter the filename

- Click OK

I-DEAS

- File >Export >Rapid Prototype File >OK

- Select the Part to be Prototyped

- Select Prototype Device >SLA500.dat >OK

- Set absolute facet deviation to 0.000395

- Select Binary >OK

Inventor

- Save Copy As

- Select STL

- Choose Options >Set to High

- Enter File Name

- Save

IronCAD

- Right Click on the part

- Part Properties >Rendering

- Set Facet Surface Smoothing to 150

- File >Export

- Choose .STL

Mechanical Desktop

- Use the AMSTLOUT command to export your STL file.

- The following command line options affect the quality of the STL and should be adjusted to produce an acceptable file.

- Angular Tolerance - This command limits the angle between the normals of adjacent triangles.

- The default setting is 15 degrees. Reducing the angle will increase the resolution of the STL file.

- Aspect Ratio - This setting controls the Height/Width ratio of the facets. A setting of 1 would mean the height of a facet is no greater than its width. The default setting is 0, ignored.

- Surface Tolerance - This setting controls the greatest distance between the edge of a facet and the actual geometry. A setting of 0.0000 causes this option to be ignored.

- Vertex Spacing - This option controls the length of the edge of a facet. The default setting is 0.0000, ignored.

ProE

- File >Save a Copy

- Set type to STL

- Set chord height to 0. The field will be replaced by minimum acceptable value.

- Set Angle Control to 1

- Choose File Name

- OK

Rhino

- File >Save As

- Select File Type >STL

- Enter a name for the STL file.

- Save

- Select Binary STL Files

SolidDesigner

- File >External >Save STL

- Select Binary mode

- Select Part

- Enter 0.001mm for Max Deviation Distance

- Click OK

SolidEdge

- File >Save As

- Set Save As Type to STL

- Options

- Set Conversion Tolerance to 0.001in or 0.0254mm.

- Set Surface Plane Angle to 45.00

- Save

SolidWorks

- File >Save As

- Set Save As Type to STL

- Options >Output As=Binary, Unit = Inches

- Resolution > Custom, Deviation Tolerance = Minimum (Slide bar to right), Angle Tolerance = 5 degrees

- OK

- Save

Think3

- File >Save As

- Set Save As Type to STL

- Save

Unigraphics

- File >Export >Rapid Prototyping

- Set Output type to Binary

- Set Triangle Tolerance to 0.0025

- Set Adjacency Tolerance to 0.12

- Set Auto Normal Gen to On

- Set Normal Display to Off

- Set Triangle Display to On