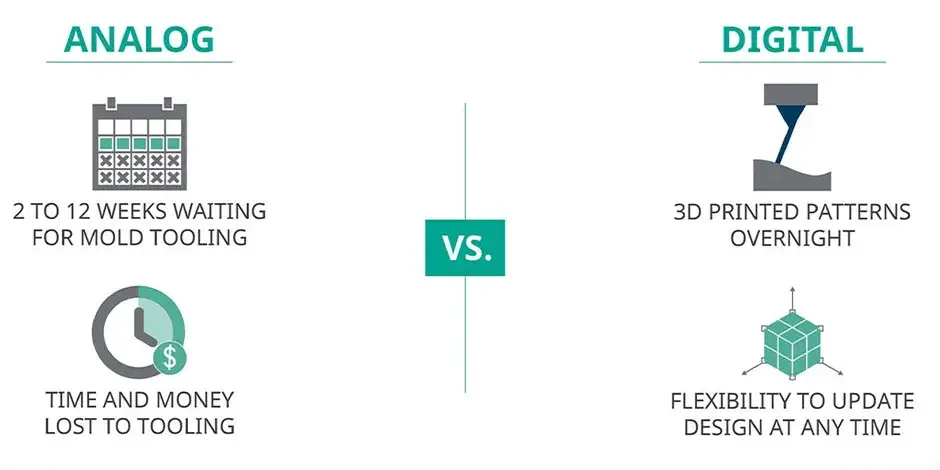

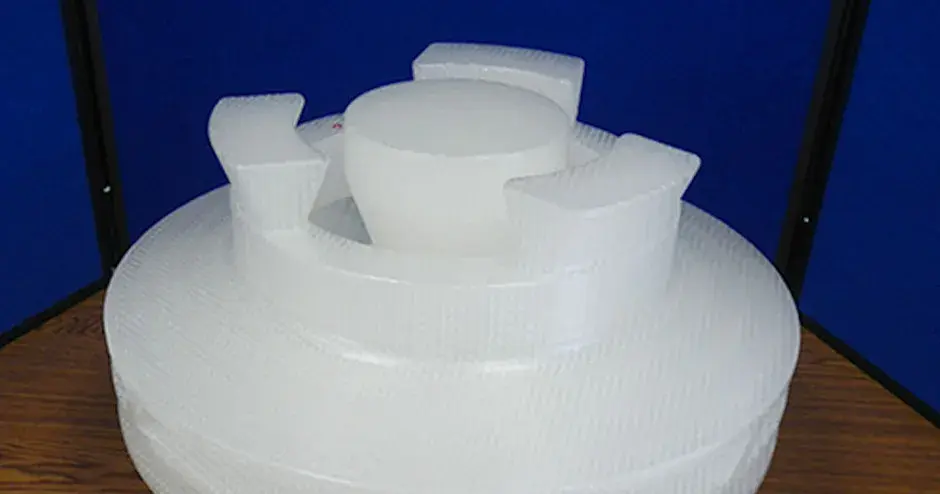

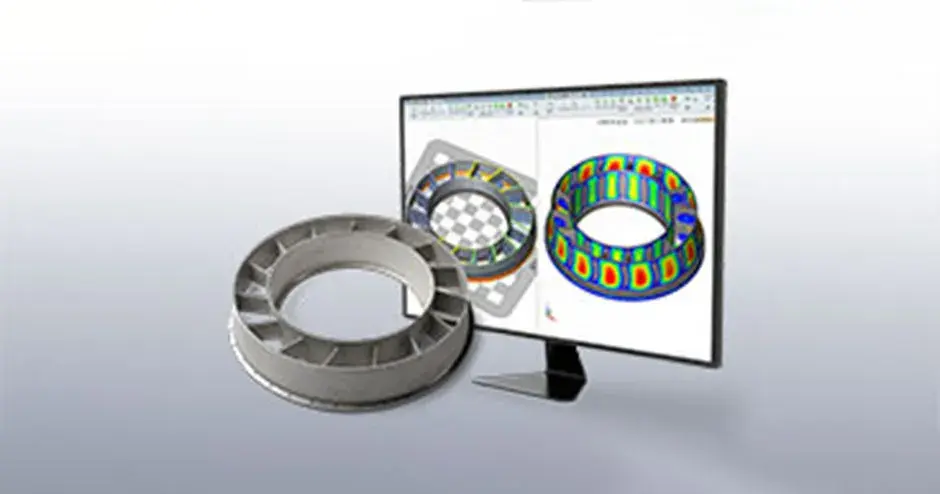

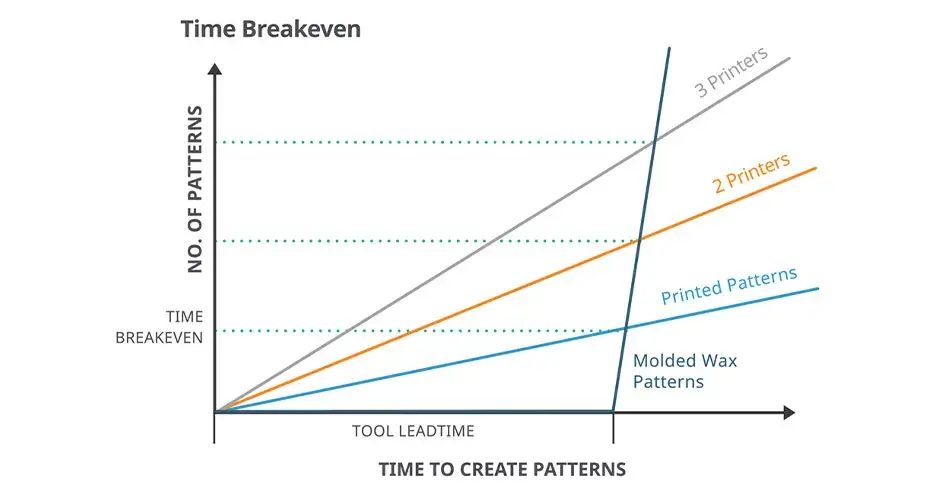

Foundries are adopting additive manufacturing solutions to address growing industry pressures that range from digitalization and the need for faster, more complex geometry patterns and molds to foundry labor shortages. In the age of the digital foundry, these solutions offer streamlined manufacturing workflows with higher degrees of automation, improved operational efficiency, as well as significant time and cost savings.

3D Systems has decades of expertise in metal casting solutions development. While investment casting foundries have been using 3D printing to produce casting patterns for decades, sand casting shops have been taking advantage of additive manufacturing in the recent years. In both cases, we have developed specific and integrated additive manufacturing (AM) solutions that maximize your productivity, reliability, flexibility, and yield – delivering your customers high quality parts while reducing total cost of ownership (TCO).