Design Optimization

The design optimization capability of our 3D printing solutions and expert consultancy advance carbon capture technology performance to accelerate decarbonization.

Up to 23x

reduction in development to production lead time

8x

reduction in required process column height

>4x

surface area increase over commercial structured packing

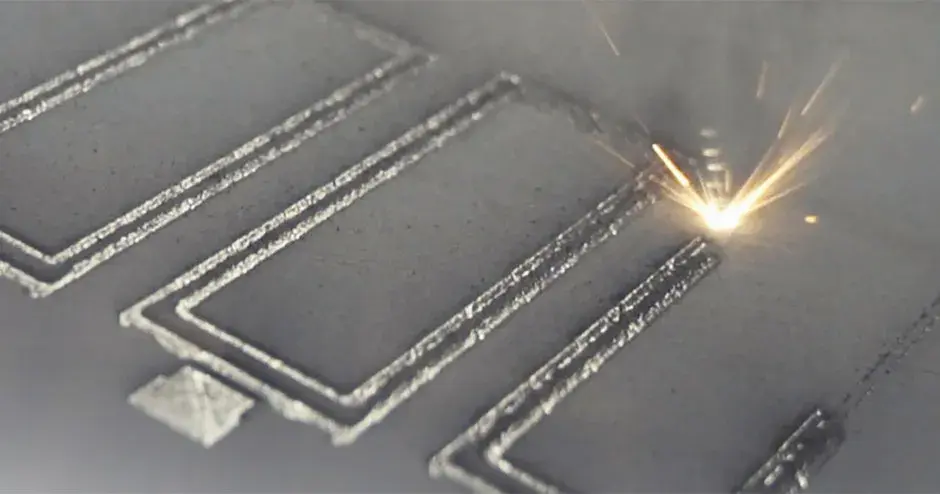

The Role of 3D Printing in Carbon Capture Technology

Removing carbon from the atmosphere requires a system of filters, heat exchangers, condensers, gas separators, and compressors. To increase direct air capture (DAC) performance and economic benefits, many of these complex components involve geometries that are well-suited to 3D printing.

Our 3D printing solutions address prototyping and production needs for a vast array of these carbon capture technology key components. Examples include: