Extrusion in 3D Printing

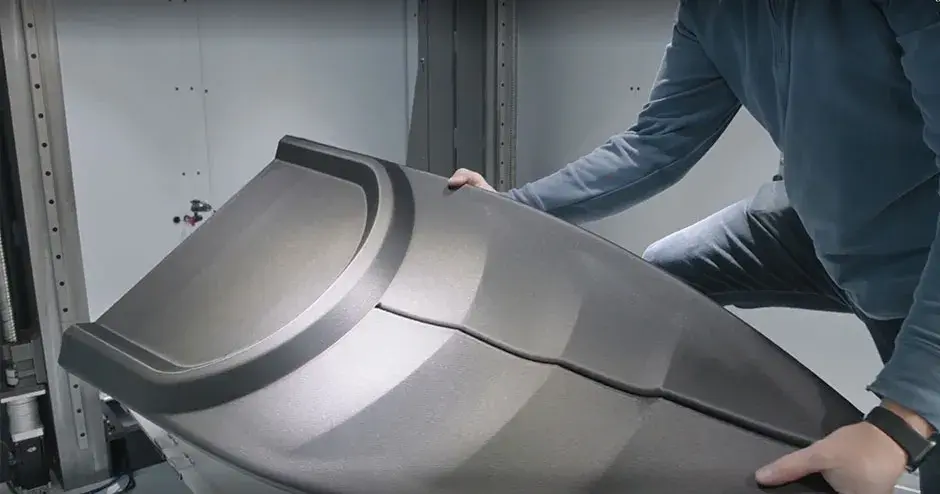

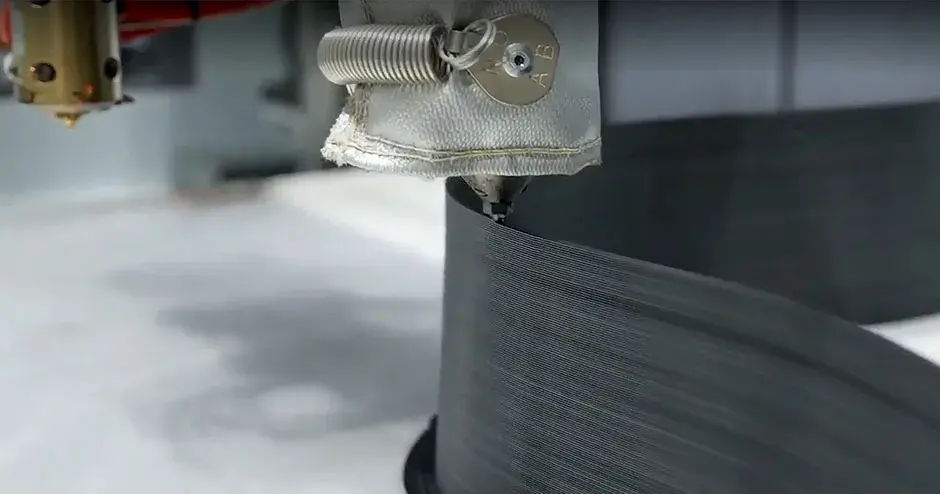

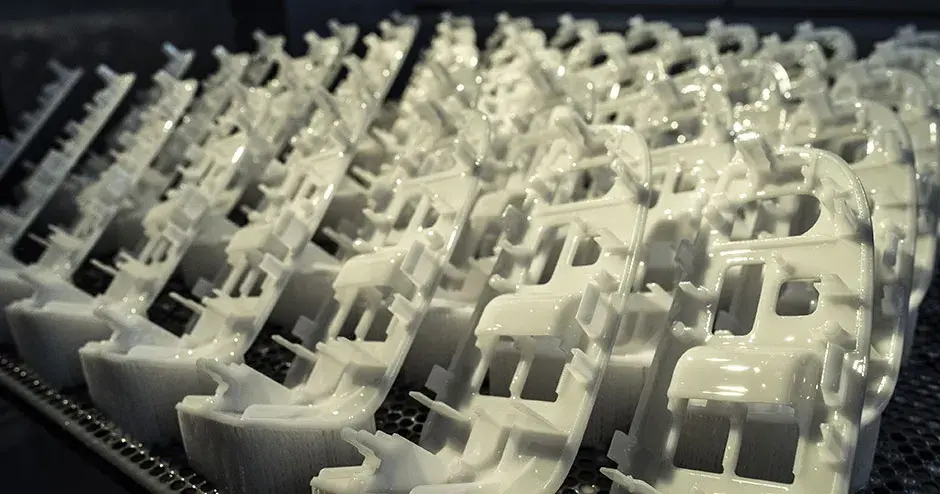

Extrusion platforms range from affordable desktop units to large-format production machines and are widely used across industries due to their versatility, low-cost feedstocks and user-friendly operation. Applications include prototyping, jigs and fixtures, tooling and patterns, end-use parts and even medical implants and instruments.

What are the primary benefits of extrusion printing?

Extrusion Applications

Extrusion Materials

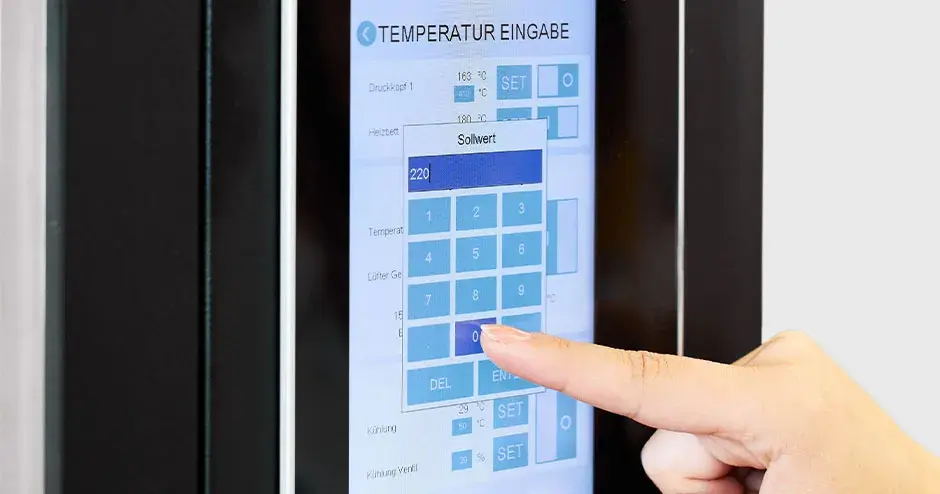

The thermoplastics used in extrusion printing are available in a wide range of formulations from commodity plastics like PLA, ABS, PETG, ASA, polycarbonate and nylon to aerospace and high-performance polymers for healthcare such as PEEK and Radel® PPSU. Elastomers and carbon-reinforced or glass-filled materials are also available. The open market for extrusion printing materials is expansive, but not every material is printable on every machine. The feedstock format, filaments or pellets, is a primary consideration, as well as maximum nozzle, bed and chamber temperatures.

Learn More About our Extrusion 3D Printers

3d Systems’ growing line of extrusion (EXT) 3D printers are reliable, high-performance machines designed for professional and industrial use. Functional parts printed on EXT machines can be found in factories, vehicles, art galleries, hospitals and even human bodies.

EXT 800 Titan Pellet

Our entry-level industrial pellet extrusion 3D printer with a compact frame that will fit through standard double doors.

EXT 1070 Titan Pellet

3D Systems’ flagship pellet extrusion printer capable of printing medium-to-large format parts, featuring a build volume of 1070mm x 1070mm x 1118mm (42" x 42" x 44").

EXT 1270 Titan Pellet

3D Systems’ largest 3D printer capable of printing full-scale parts up to 6 feet tall with direct pellet-fed 3D printing.

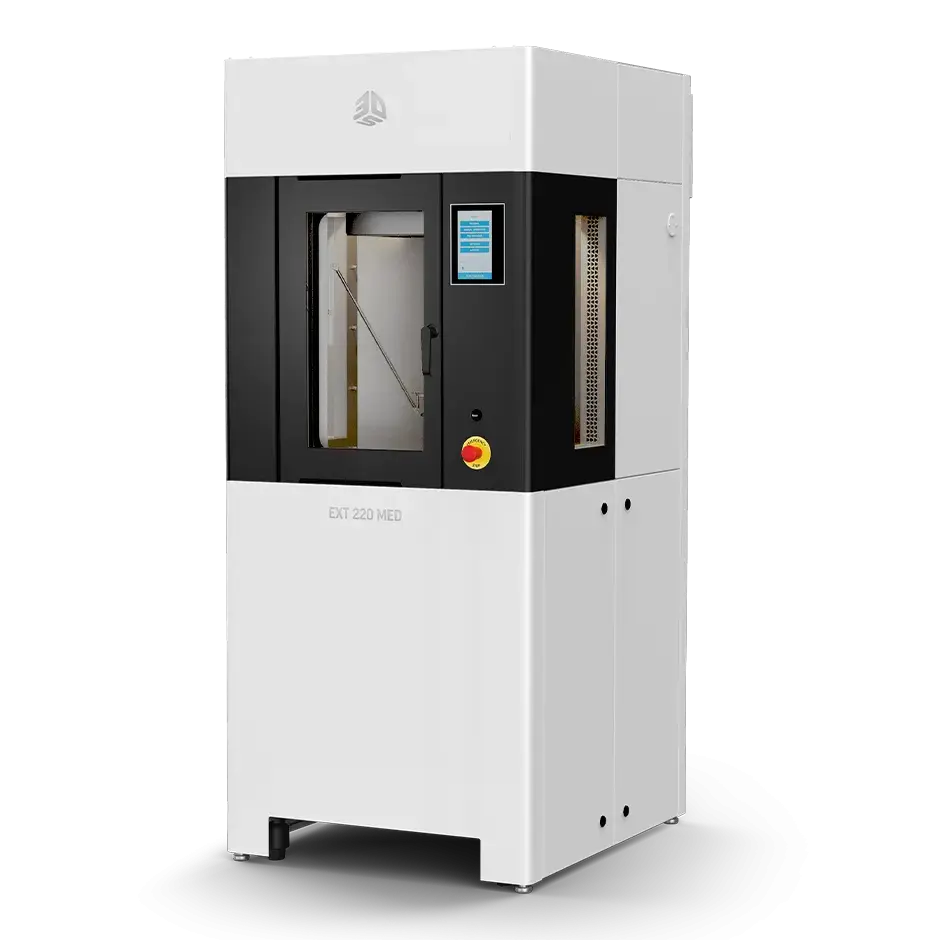

EXT 220 MED

The only extrusion platform that features an integrated clean room and is validated by leading medical device manufacturers and hospitals worldwide.