Gain a competitive edge in sustainability, customization, adaptability and asset readiness with our additive manufacturing solutions and services

In order to grow and differentiate from the competition, commercial and public transportation companies are pushing for lower costs, enhanced performance, and flexible product platforms that can quickly adapt to new technologies and customer requirements.

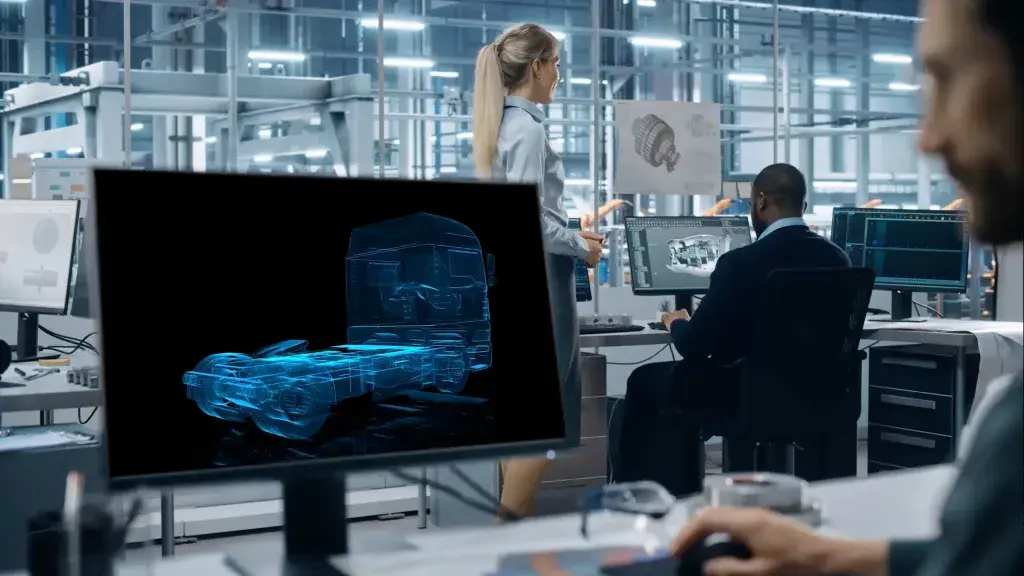

Our extensive portfolio of additive manufacturing technologies, materials, and software can give you the competitive advantage you need to meet these challenges. Through our understanding of the application needs for the railway, truck, and bus industries, we will empower your innovation.

Accelerate new technologies to improve commercial vehicle efficiency and meet your environmental sustainability objectives with innovative drive train systems. Help your customers modernize and optimize existing fleets. Reduce development and implementation cycle time with help from our additive manufacturing and transportation industry experts.

3D Systems can support your vertical integration strategies with our wide variety of additive manufacturing technologies, production-grade materials, manufacturing operating system software, and expertise in commercial and public transportation applications. Keep your assembly lines running with bridge production solutions and optimized tooling, and support your customers with on-demand spare, or hard-to-find parts.

Stay ahead of the competition with agile responses to changing regulations and grow your business by quickly addressing customer needs with help from our additive manufacturing solutions and leading expertise. We can help you find competitive solutions for product customization to increase your presence in niche markets and implement flexible and scalable manufacturing processes to accelerate product delivery.

EV manufacturers are under pressure to accelerate product development cycles, control production costs and create aesthetically pleasing designs. These needs align perfectly with the capabilities of additive manufacturing, as it streamlines every step of the design and manufacturing process, from prototyping to bridge production and spare parts.

Space in the vehicle is constrained, but critical components like electrical wiring, hoses, and tubes need to be routed in restricted space. Find out how you can satisfy the increasing requirements of new propulsion systems and vehicle architectures with optimized retention components.

Metal 3D printing enables unprecedented improvements in fluid dynamic applications for power electronic systems for truck, bus, and rail to improve system efficiency, optimize space utilization and reduce part weight.

Learn best practices and find out how additive manufacturing delivers design intent for interior components earlier to accelerate interior vehicle and cabin design and testing to reduce overall costs.

Learn how to evaluate AM materials for production with examples from the Figure 4 materials portfolio and discover the qualifications and ASTM and ISO standards testing that matter.