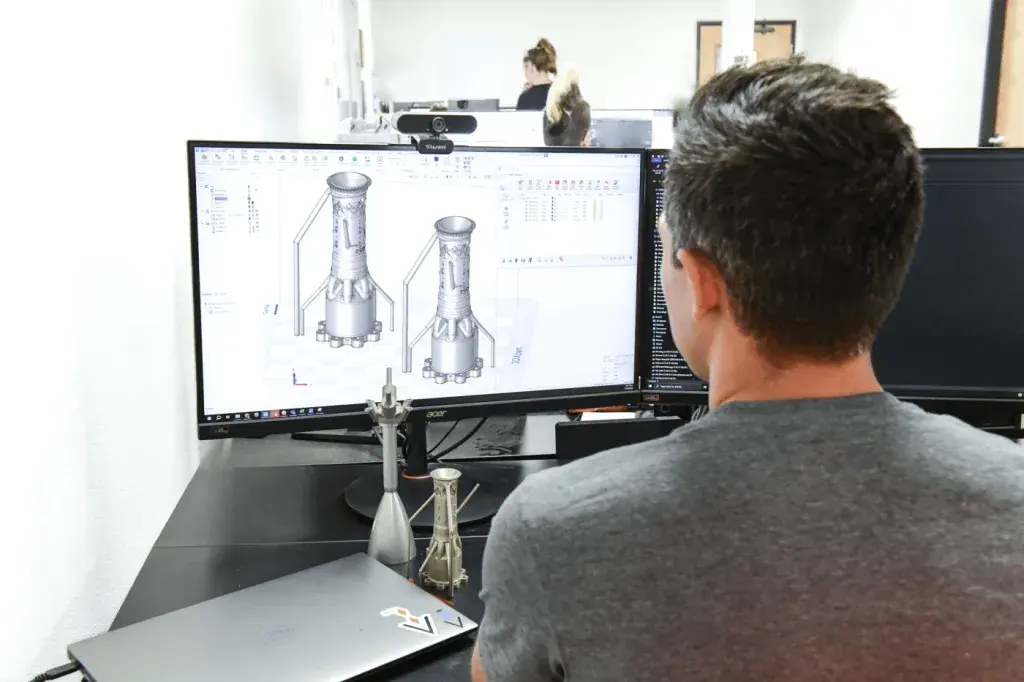

Accelerate and de-risk your additive manufacturing application development

2K+

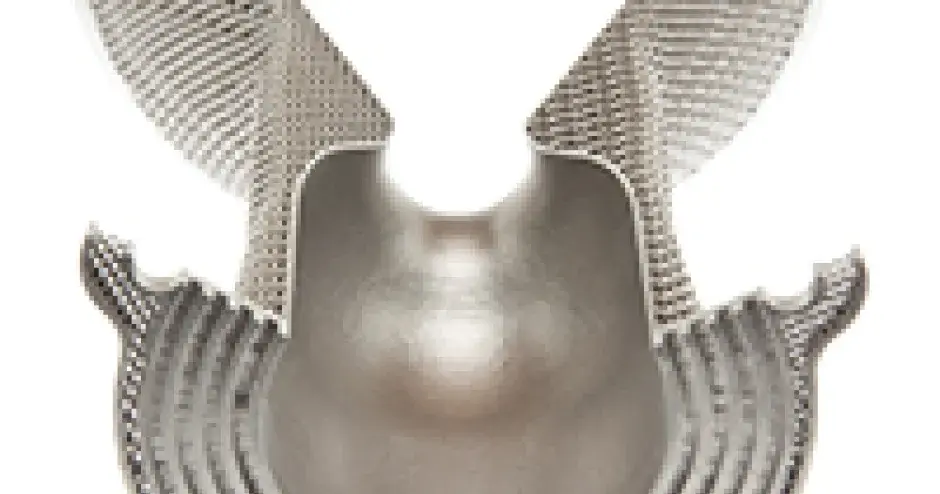

Structural Ti or Al-alloy components for space flight since 2015

200+

Critical Passive RF flight parts since 2017

15+

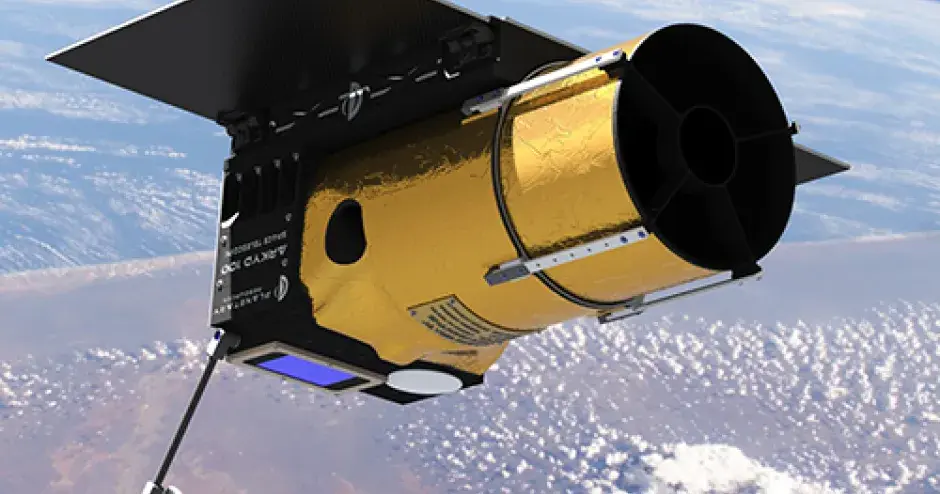

Satellites with 3D Systems produced flight hardware on board

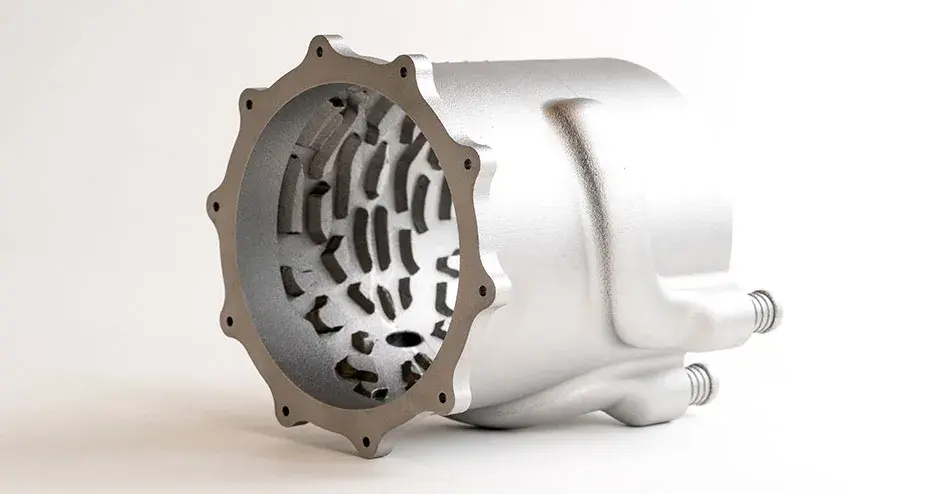

Reduce Weight, Improve Functionality, and Consolidate Parts

Additive Manufacturing Applications for Aerospace and Defense

Customer Stories