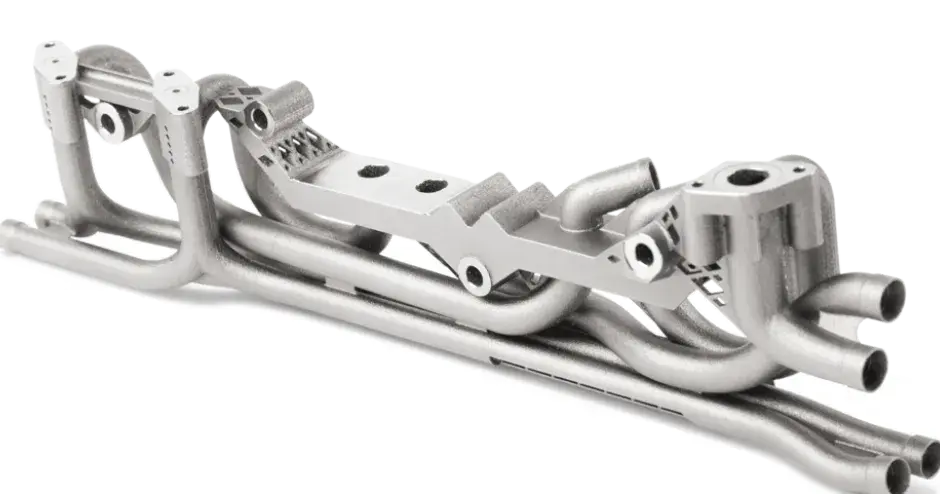

To gain a competitive advantage, we understand your need to differentiate your digital manufacturing services business and to become increasingly responsive to customer requirements, from prototype to production. We also understand the critical importance to improve your operation’s productivity and profitability, from streamlined manufacturing workflows to higher degrees of automation.

3D Systems has three decades of expertise in application development across all major industry verticals and manufacturing processes to address your customers’ challenges. We have developed the broadest range of integrated additive manufacturing (AM) solutions that maximize your productivity, reliability, uptime, and yield – delivering your customers high quality parts while realizing exceptional total cost of ownership (TCO).