On June 18, 2018, 3D Systems announced a new On Demand Anatomical Modeling Service. This new service provides a wide range of medical professionals with access to anatomical models 3D printed from their 3D digital files, enabling 3D visualization and patient education.

3D Systems had a chance to sit down with Katie Weimer, vice president of medical devices, to learn more about the impact of this important offering.

3D Systems: Katie, why is this such an important announcement?

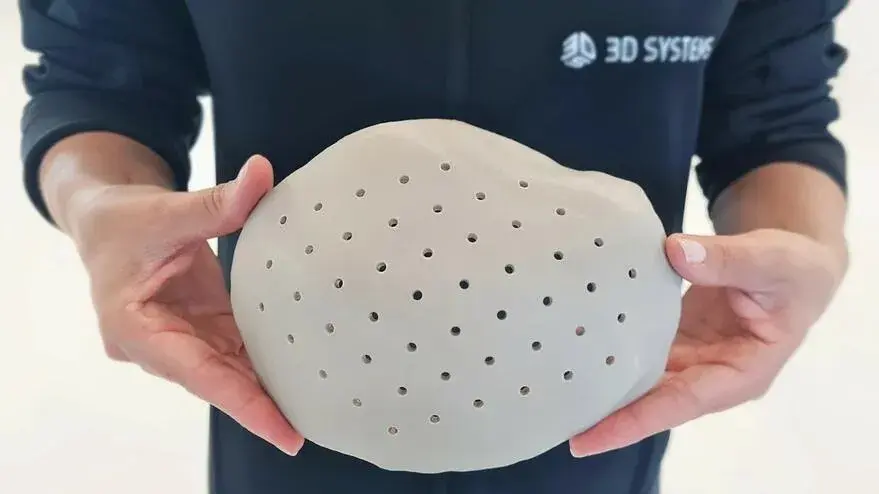

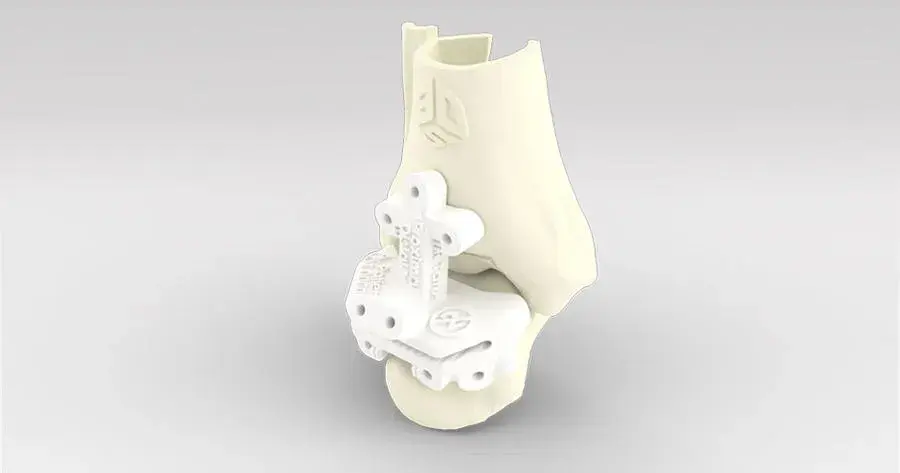

Katie: The healthcare industry is seeing the benefits provided through 3D printed patient-specific anatomical models, like 3D visualization of the anatomy subject at hand or educating a patient. Our goal is to make 3D printed models easier and more accessible to a broader range of the healthcare community.

3D Systems: How can medical professionals get access to models?

Katie: It’s a really easy 3-step process.

- Medical professionals like surgeons, radiologists, and lab technicians can easily upload a 3D model file (i.e., STL, OBJ or PLY) to the company’s On Demand Anatomical Models website. Model files can be prepared with 3D Systems’ D2P™ software or any commercially available medical image processing software.

- Customers select from a variety of materials from which to print depending on the use and desired areas to highlight in the model, and then request an instant quote.

- After reviewing the quote, the requestor can place the order in just one click, and the finished model will arrive in approximately five business days.

3D Systems: Will you continue to offer full-service virtual surgical planning and anatomical modeling services?

Katie: Absolutely. We work on thousands of cases with medical professionals wanting to produce Patient-Specific Anatomical Models for diagnostic purposes and pre-surgical planning. After the medical professional provides a CT (Computed Tomography) or MR (Magnetic Resonance) scan of their patient to our team, the company’s biomedical engineers process the data, design the model and 3D print it at the Denver healthcare manufacturing facility. We even offer a variety of materials that can also be used in a sterile operating room environment for consultation during a procedure.

3D Systems: Is there anything else our readers should know?

Katie: Yes! For the first time ever, we’re able to take over 25 years of experience and put the complicated anatomical workflow in the hands of medical professionals with an easy-to-use order process. It used to only be initiated through a phone call, but now any medical professional can order an anatomical model with the click of a button. I feel proud that we’re able to empower medical professionals to adopt this technology that may not have been available to them before. It affords them the wider opportunity to use anatomical models for patient care.