3D Printing with Nylon

There is no denying the conceptual advantages of 3D printing. You can design and manufacture more organic shapes that are tailored to the end function of whatever you are trying to make. When it comes to practical applications, however, every engineer knows material properties matter. That’s why your choice of 3D printing technology is important, with different additive technologies offering different sets of advantages and disadvantages.

When you need ultra-smooth surfaces for aesthetic prototype models for example, you may decide to steer towards photopolymer-based 3D printing materials and printers. Conversely, when the parts you are printing need to be made of functional, tough thermoplastics, then selective laser sintering (SLS) may be the right choice for you.

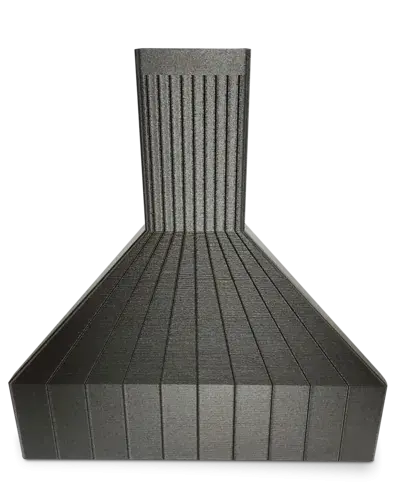

SLS 3D printing and DuraForm® materials by 3D Systems use a variety of true thermoplastic nylon-based materials to deliver parts that are strong and durable with the mechanical and chemical characteristics of many engineering plastics, elastomers and composites.

Core among these are varieties of PA11 and PA12, but novel chemistries are available as well that enable high performance, ease of processing and a significantly lower price point that enables new applications. 3D Systems’ new DuraForm PAx is one of these materials and offers a very high recycling ratio as part of its economic advantage. It also melts at a lower temperature, enabling parts to cool more quickly out of the 3D printer, which improves part-in-hand delivery time while reducing maintenance requirements on the printer itself. All very compelling advantages for cost-effective innovation!

Investigating and understanding material performance is key to adopting any manufacturing process. For companies not yet using additive manufacturing, however, many other questions often arise around the process itself. Post-processing and integration with the larger manufacturing workflow are also concerns.

To help you make the right choice, we have assembled a new and comprehensive white paper: Choose the Right Nylon for Your Application. Discover what materials and properties are available and how to reap the greatest advantages from SLS 3D printing technology, including how to:

- Increase cost-efficiency and productivity

- Deliver superior part finish, performance and innovation

- Meet your sustainability goals

Read through it here and reach out with any questions you have. You may be surprised by what’s possible.