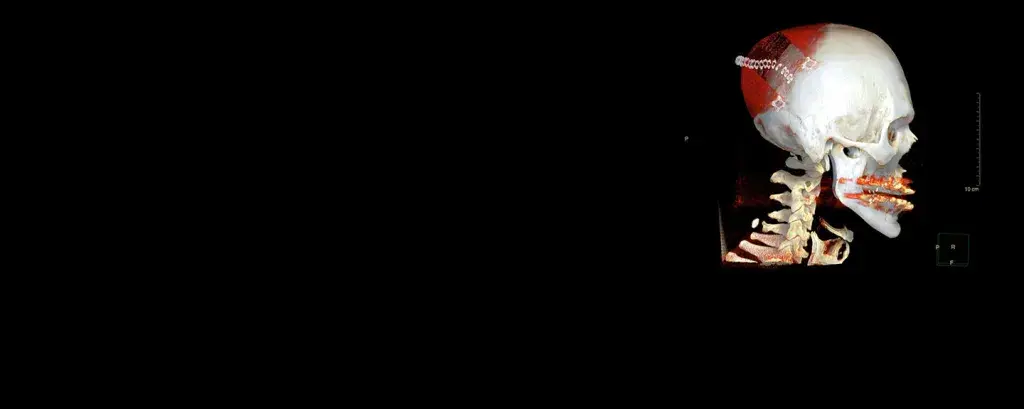

The rapid development of 3D printing technologies has opened new possibilities, not only in industry and design but also in the field of medicine. The case of Rainer Trummer, a 55-year-old computer scientist from Salzburg, is a striking example. Trummer has been suffering from a skull anomaly since birth, which caused both physical and psychological problems. However, high costs and the lack of technical capabilities made corrective surgery for the abnormality impossible for a long time. Until now.

The patient, Rainer Trummer, stands with one of his attending physicians and hospital IT staffer that made it possible to receive his 3D printed PEEK cranial implant.

The Challenge

Trummer's skull anomaly developed in his early childhood, as the skull sutures fused prematurely and unevenly. This resulted in a significant asymmetric deformity and reduced volume of the skull, causing psychological distress throughout Trummer's life. “I still remember the swim classes during my school days. I had grown my hair longer back then to hide my flat skull,” recalls Trummer. “Unfortunately, it didn't help much during the lessons because whenever my hair got wet, my deformity became visible. That didn't go unnoticed by my classmates, of course.”

The bullying Trummer endured since childhood fuelled his desire for cosmetic surgery. However, at that time, the necessary technological capabilities were not yet available. The associated financial burden added to the challenge, as Trummer's health insurance considered the deformity's impact not significant enough to support such an operation.

Furthermore, the search for a suitable solution proved difficult both aesthetically and functionally. It was necessary to develop an implant that was both aesthetically appealing and met Trummer's specific requirements. The goal was to design a lightweight implant that would not be sensitive to temperature changes- especially since Trummer lives in the mountains. Additionally, it had to account for Trummer's fully developed skull bone. So, how could the implant be placed while ensuring sufficient skin coverage after insertion and achieving optimal aesthetic integration?

The Solution

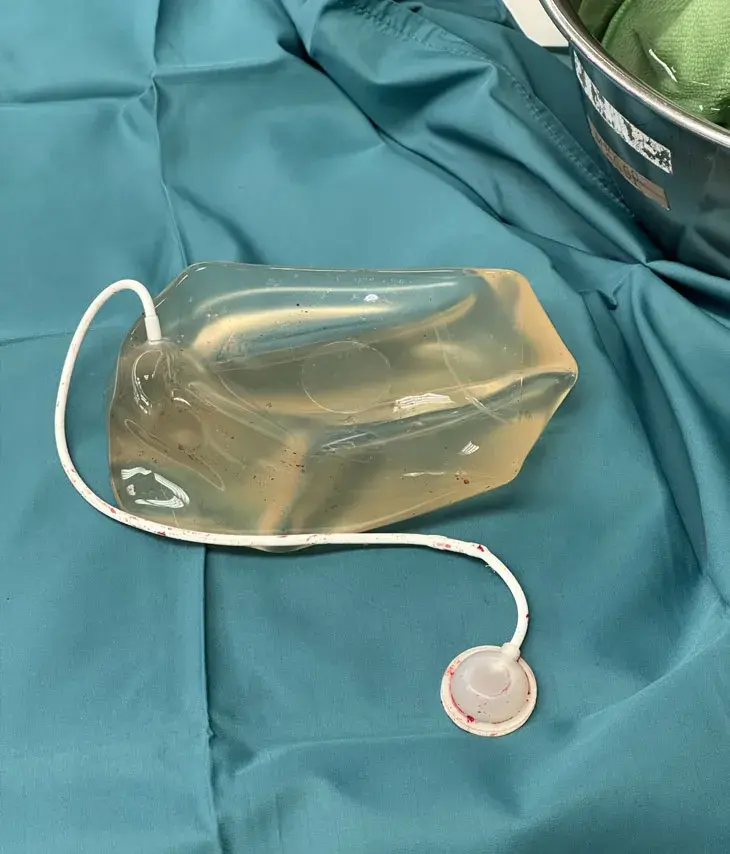

In preparation for surgery, Mr. Trummer had a preliminary procedure to place an expander to stretch his scalp so that the implant would fit properly.

After much planning and preparation, Univ. Prof. DDr. Alexander Goggi successfully implants the PEEK cranial plate.

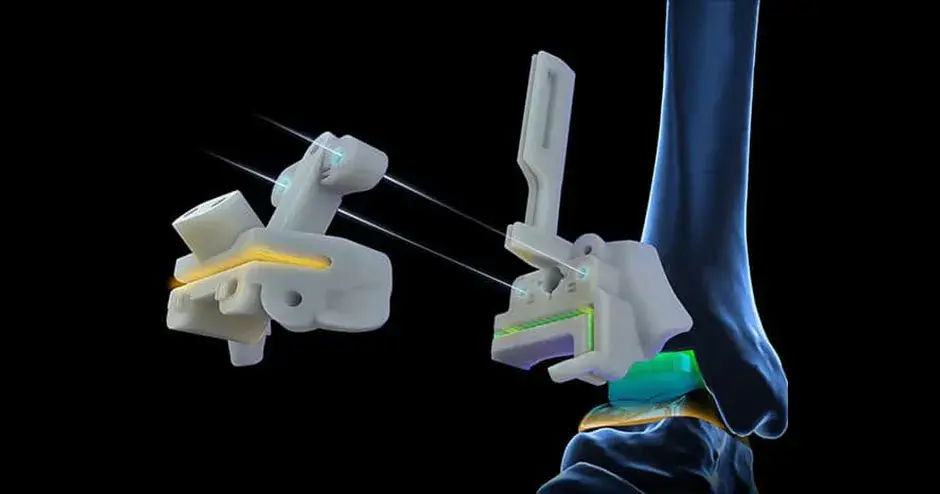

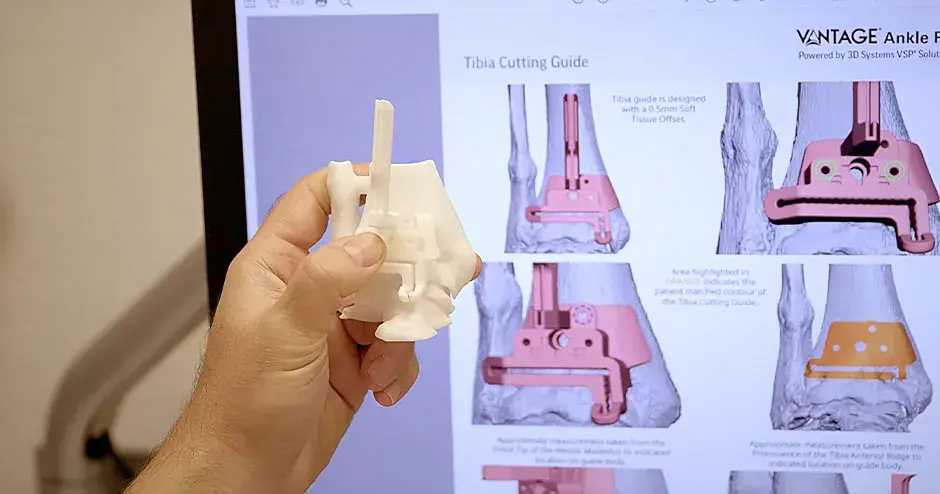

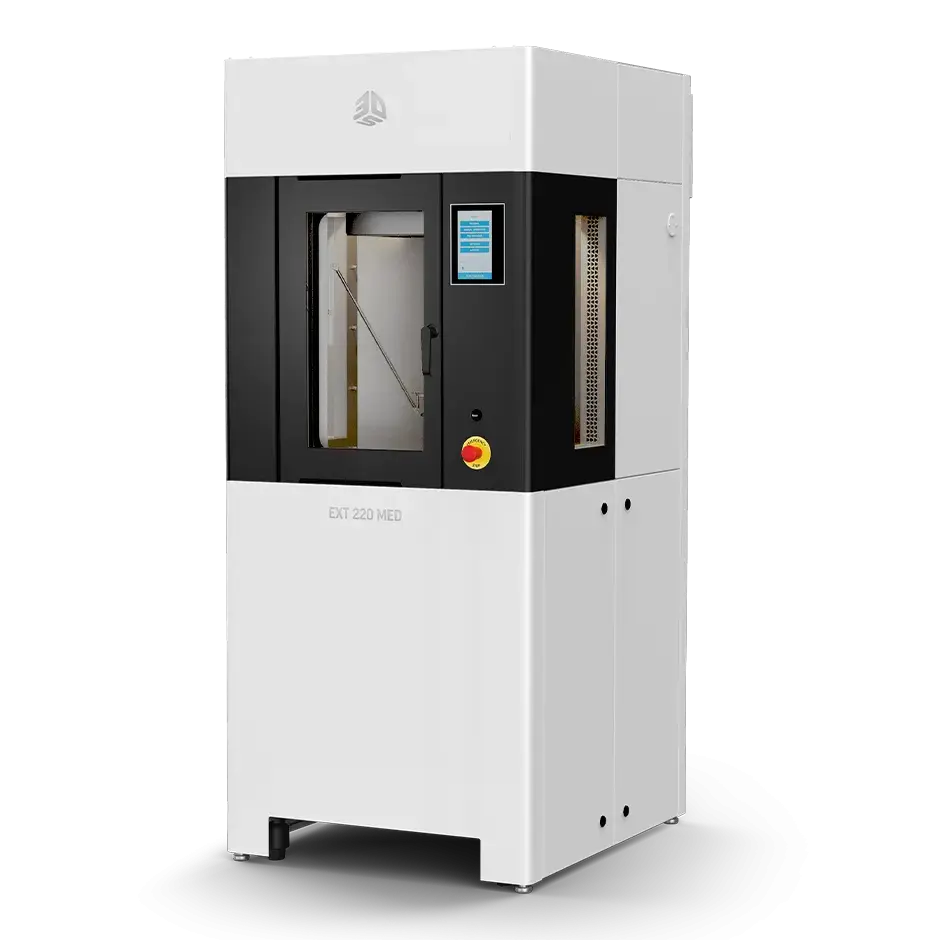

Salzburg University Hospital utilized additive manufacturing technologies for point-of-care 3D printing from 3D Systems to develop a skull implant for Mr. Trummer. The implant had a diameter of 12 centimeters and measured three centimeters at its widest point. The Salzburger Landeskliniken played a pioneering role in this endeavor, having established their own laboratory with 3D Systems’ 3D printer at the university hospital in 2021. This was only possible thanks to the excellent interdisciplinary collaboration between the Department of Medical and Information Technology (MIT) and the medical department, in this case the Department for Oral and Maxillofacial Surgery / University Clinic Salzburg. Trummer became the first patient equipped with an implant from the hospital’s own EXT 220 MED 3D printer, capable of printing implants made of PEEK plastic under cleanroom conditions. PEEK is an ideal material for manufacturing medical devices as it is lightweight, resistant to thermal and ionizing radiation, and possesses mechanical properties similar to human bone.

To achieve an aesthetically satisfying result, the experts decided to use an expander. Over several months, the expander was gradually filled with a total of 260 milliliters of saline solution to stretch the scalp enough to fully cover the implant.

The entire preparation and operation time took about one and a half years. The actual surgical procedure involved removing the expander, fixation with mini plates and screws, and wound care. After the operation, a natural tissue layer is formed, further stabilizing the implant.

The Result

3D printing provided a solution to many of the challenges that had hindered such an operation for many years. “During the production phase, we printed the implant in both solid and lattice complete and different structures to find the solution that would yield the best result for the patient,” said Stefan Leonhardt, director of medical devices at 3D Systems. “Ultimately, the honeycomb structure proved to be the best option, allowing us to reduce approximately 40 percent of the total weight of the fully printed implant.” Additional advantages of the 3D-printed implant include a short production time of only 10 hours and its biocompatibility for long-term use in the body.

The implant was placed directly on the skull to reconstruct the missing shape.

Throughout the entire procedure, Trummer did not experience any pain except for the discomfort caused by the expander. Both physically and psychologically, his condition improved significantly after the procedure, boosting his self-confidence, and enhancing his overall quality of life. “I feel really great, and I would make this decision again without hesitation,” said Trummer. “Finally, as an enthusiastic motorcyclist, I can enjoy my rides without any problems with the size and fit of my helmet. Although it took some time for my mind to get used to the new size and shape of my head, after a few weeks, it felt as if it had always been this way.”

Following his groundbreaking procedure, Mr. Trummer visits the facility that developed the technology to 3D print his PEEK cranial plate.

The Outlook

The partnership between 3D Systems and the Salzburger Landeskliniken is based on the shared goal of utilizing additive manufacturing at the point-of-care to ensure faster, safer, and optimal care for patients.

“With the help of 3D Systems and their technology, we aim to make more affordable 3D-printed implants accessible to a broader range of the population in the future,” says Prof. Dr. Simon Enzinger, executive senior physician at the Salzburger Landeskliniken. “This not only gives patients in maxillofacial surgery the opportunity for completely personalized implants but our specially established print center also has the potential to revolutionize achievable results in other medical areas.”

The implant used for Mr. Trummer was a custom-made treatment, targeted for a specific clinical need. To make implants, printed at the point-of-care, accessible to a broader range it is important to fulfill all requirements of the Medical Device Regulation (MDR). A company called POC APP AG developed, together with the University Hospital Basel and 3D Systems, a program that can be transferred to hospitals and support their regulatory roadmap. This solution has been applied at the University Hospital Salzburg throughout the past months, ensuring that all necessary documents and data are available for future cases.

Furthermore, 3D Systems, in collaboration with the Salzburger Landeskliniken, is actively involved in the development of new materials and structures for implants, aiming to set new standards in medical care. Continuous technological advancements are crucial for further improving treatment options and promoting the well-being of patients. 3D Systems firmly believes that 3D printing represents the future of medicine and is proud of the success achieved so far in collaboration with the Salzburger Landeskliniken.