Sample Application

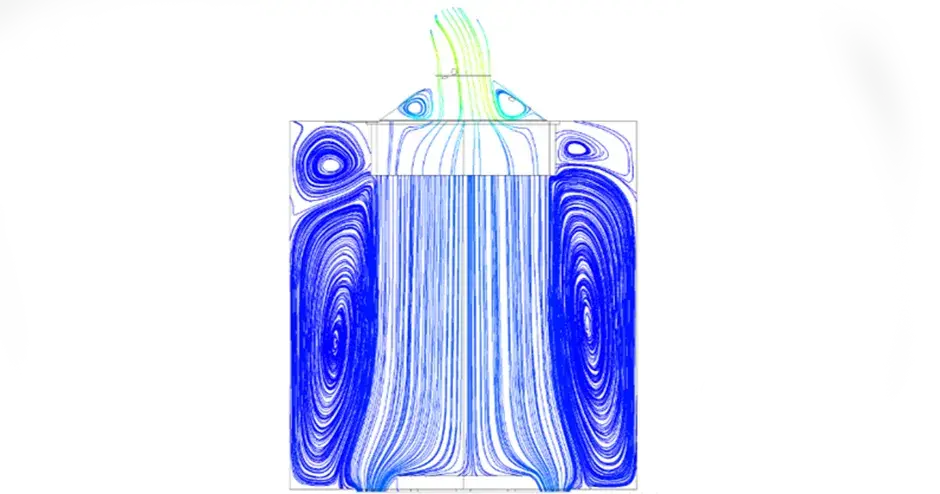

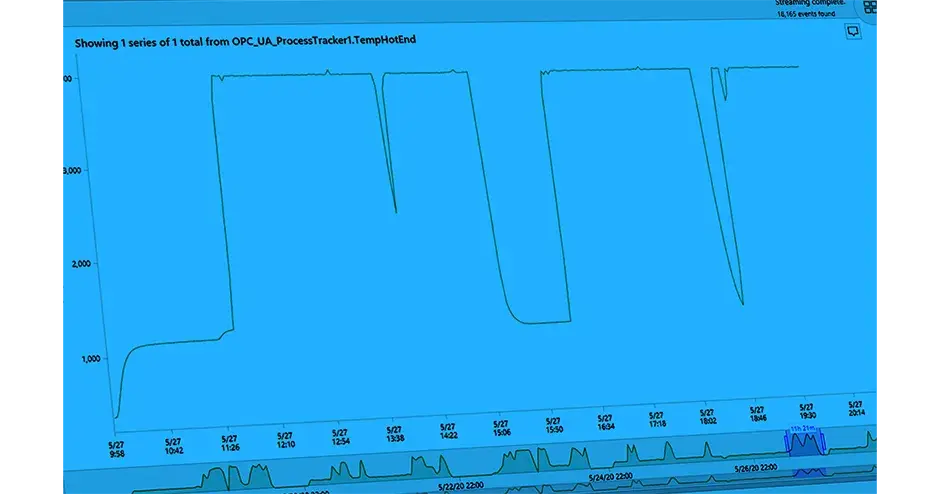

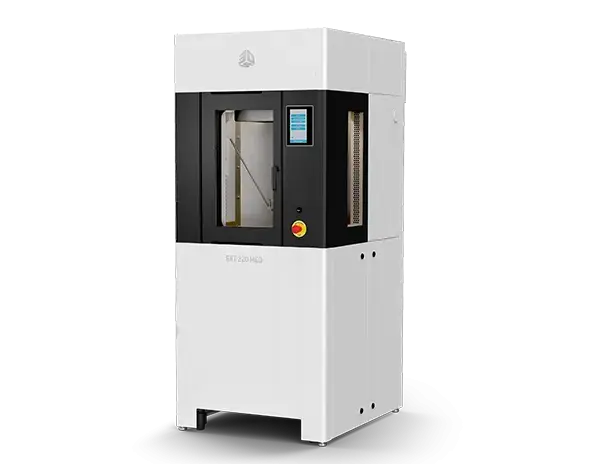

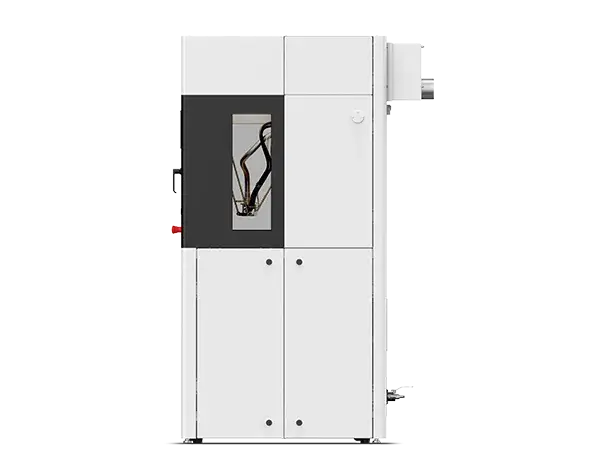

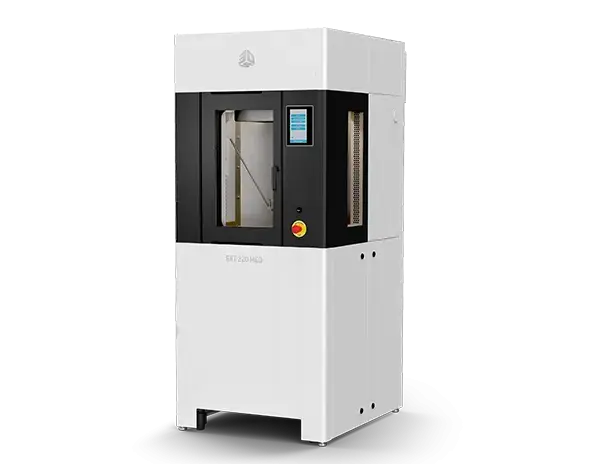

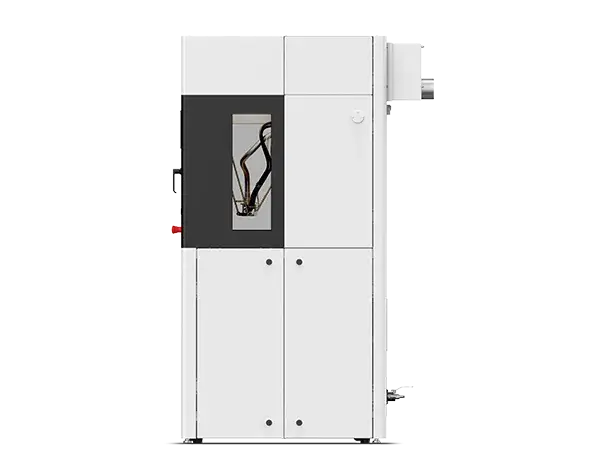

The EXT 220 MED with its filament-based extrusion technology enables printing of medical implants and instruments using high performance polymers, including PEEK, resomers and Radel® PPSU. It is the only platform with an integrated clean room and temperature controls to enable high-quality device production.

Sample Applications

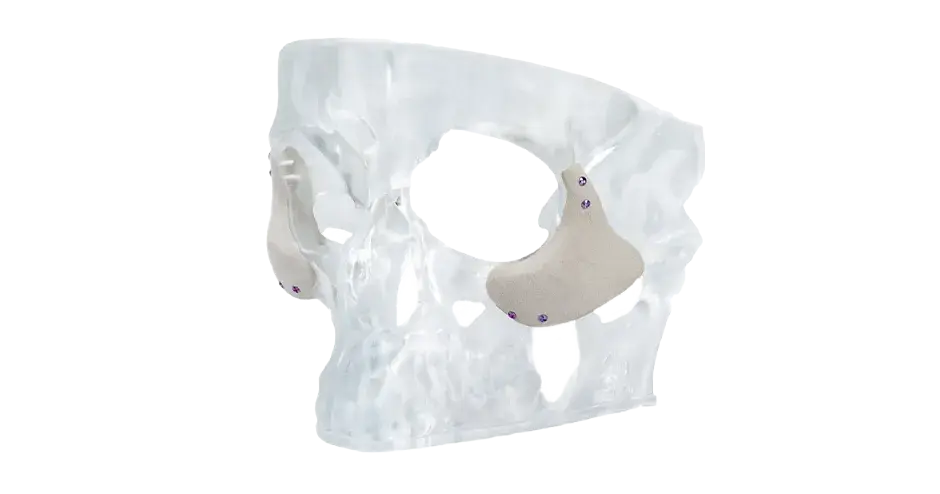

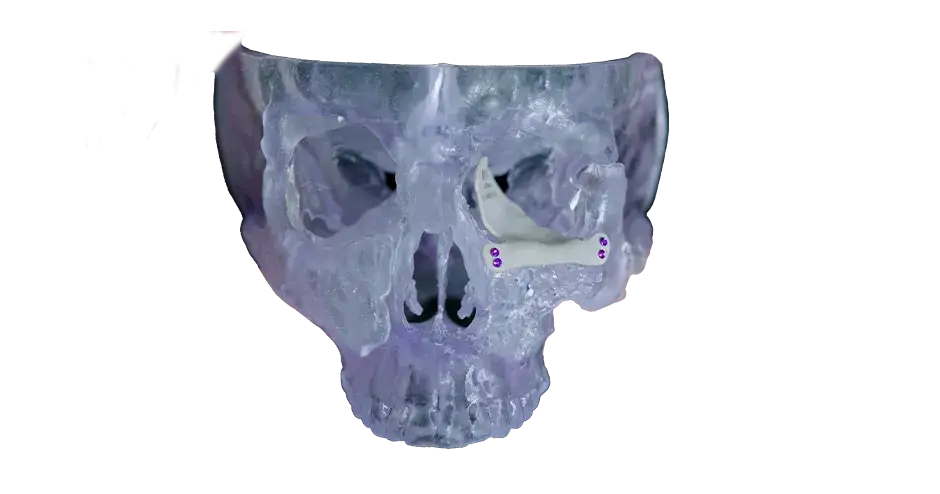

Compatible Materials for the EXT 220 MED Printer

PEEK Material

High-performance, biocompatible polymer ideal for medical implants

Radel PPSU (Polyphenylsulfone)

High impact strength polymer ideal for sterilizable medical instruments