Customer Need

Fuel rapid and constant automotive development to drive performance improvements.

Solution

High speed, high quality, high throughput 3D printing with best-in-class materials using 3D Systems proven stereolithography (SLA) and selective laser sintering (SLS) machines.

Outcome

- 100-150 part sets printed daily

- More productive aerodynamic development cycles with high speed, throughput, and accuracy of test parts to optimize regulated testing time

- Cost-effective production of complex and low volume production parts and tooling

Sauber Motorsports AG has built a highly productive in-house factory to support its high demand wind tunnel operations that was enabled by a 3D Systems solutions and long-term partnership. High throughput 3D Systems equipment and solution expertise coupled with best-in-class materials provides the high-quality parts needed for Sauber to test more aerodynamic model iterations.

Factory-Level Throughput Drives Constant Development

The pace of innovation at Sauber is relentless. In order to maximize its ability to drive rapid development on its car, Sauber Engineering has invested in an additive manufacturing machine park that is among the largest of its kind in Europe. Due to the proven throughput, quality, accuracy, and choice of best-in-class materials with 3D Systems 3D printers, this park includes fifteen 3D Systems machines across technologies.

According to Christoph Hansen, Director of Technology and Innovation at Sauber Engineering, additive manufacturing is an integral part of every Formula One team because it provides faster access to parts than conventional manufacturing methods. “Creating something in carbon fiber can take weeks before a single part is ready,” said Hansen. “Conventionally producing the quantity of parts we need for progress would be impossible in the time we have.”

Due to this need for speed, Hansen said lead time was the most important factor when selecting a 3D printing partner. However, it was not the only factor: “You have to produce more options to compete on the development side, but it’s not just banging out as many parts as possible. You also have to test and be sure it’s correct,” Hansen said.

Best-In-Class Materials Ensure High Quality Results

For the highest confidence in test results, best-in-class materials are necessary. At Sauber Group, part stiffness and surface finish are essential. Sauber Engineering produces an average of 100-150 3D printed part sets daily using 3D Systems machines. Of these, eighty- to ninety percent are SLA parts for wind tunnel testing that are printed using a selection of Accura® SLA materials, including:

-

Accura® HPC material, a high-speed, high-rigidity engineered nanocomposite

-

Accura® Bluestone material, a composite material for stable, high stiffness parts

-

Accura® Xtreme material, an ultra-tough grey plastic

Combined with Sauber Motorsport’s confidence in the quality of Accura materials, this high level of daily part production is critical to the team’s progress and ultimate success. “On each cycle we normally find an improvement,” said Reto Trachsel, Head of Aero Design at Sauber Motorsport, “and if you can now do 50 cycles it makes a big difference. The quicker we can produce the parts, the quicker our development cycles are, and the more progress we can make in our aerodynamics.”

- Christoph Hansen, Director of Technology and Innovation, Sauber Engineering

- Christoph Hansen

Proven Quality Machines

Sauber Engineering uses 3D Systems ProX® 800 printers to produce its SLA parts. This large-scale SLA printer features a maximum build envelope capacity of 650 mm x 750 mm x 550 mm (25.6 in x 29.5 in x 21.65 in), and delivers high accuracy and precision. By using two laser spot sizes per layer, the ProX 800 maintains high print speeds without compromising feature details.

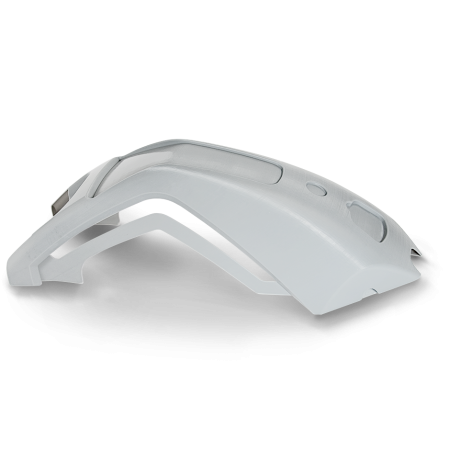

Beyond parts for wind tunnel testing, Sauber Engineering uses SLA to produce carbon fiber tooling and SLS for a variety of purposes, from miscellaneous jigs and tooling to low-volume, end-use parts for the car itself. Sauber Engineering uses additive manufacturing for end-use part production based on a combination of the convenience, complexity, and economics offered by this technology for low-volume parts like ducting, electronic boxes, and pit-stop equipment, and uses a proprietary carbon-reinforced SLS material.

According to Hansen, the machine architecture of 3D Systems’ SLS was the deciding factor in choosing this equipment because 3D Systems’ SLS machines use a roller mechanism to lay down subsequent layers of material instead of a wiper. This method delivers a smooth and fully flattened layer of material, whereas a wiper mechanism can agitate the material and sometimes result in system crashes. 3D Systems’ roller method compacts the powder, resulting in uniform layers that deliver stronger parts.

Nonstop Productivity Fuels Innovation

In the highly competitive world of Formula One, making constant progress in the face of ever-tightening regulations is a challenge. Sauber Engineering overcomes this challenge by using 3D Systems’ proven technologies to maximize its capabilities. An in-house factory of 3D Systems’ machines gives Sauber Engineering high throughput productivity, high-quality parts, and best-in-class materials selection to keep pushing development faster and farther. Using the expertise it has gained using additive manufacturing in motorsports, Sauber Engineering offers part manufacturing to customers in diverse industries.