Streamlined production workflows and technology that enables higher yield, efficiency of scale, repeatability, process reliability, fastest time-to-part in hand, unrivaled uptime and increased capacity

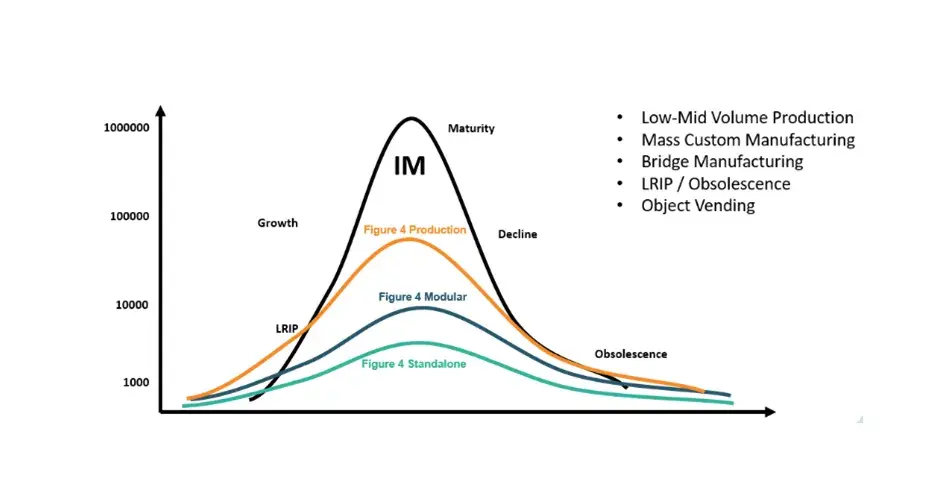

Additive manufacturing (AM) is transitioning from a primarily prototyping tool to scaled manufacturing. This is especially the case for pixel-based 3D printing technologies that already offer high-speed 3D printed parts.

To support this, new 3D printing photopolymer materials are being developed with production-capable properties for use in application-specific industries.

With the advance of production-capable 3D printed photopolymers and greater overall 3D printer workflow productivity, it is now possible to achieve a significant boost in build efficiency.

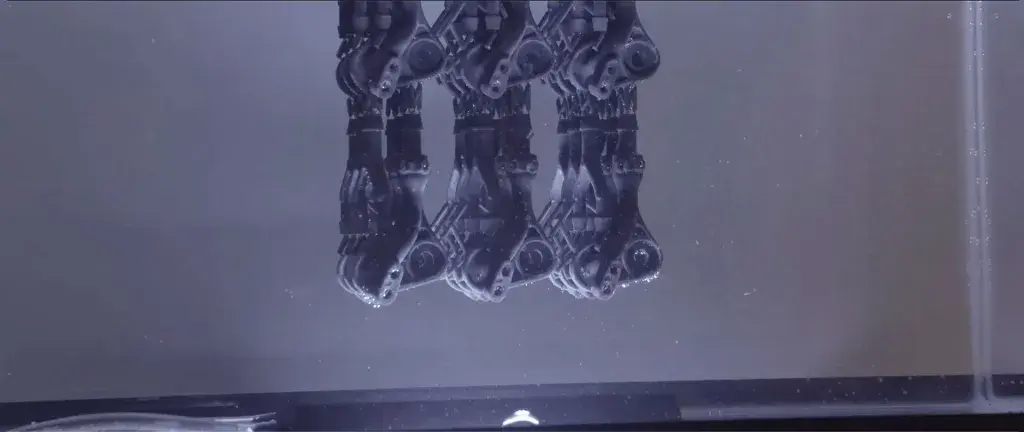

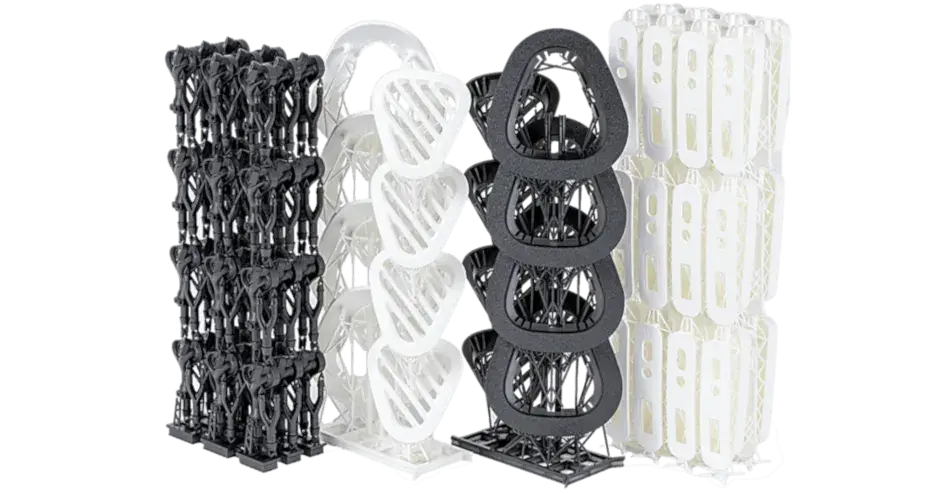

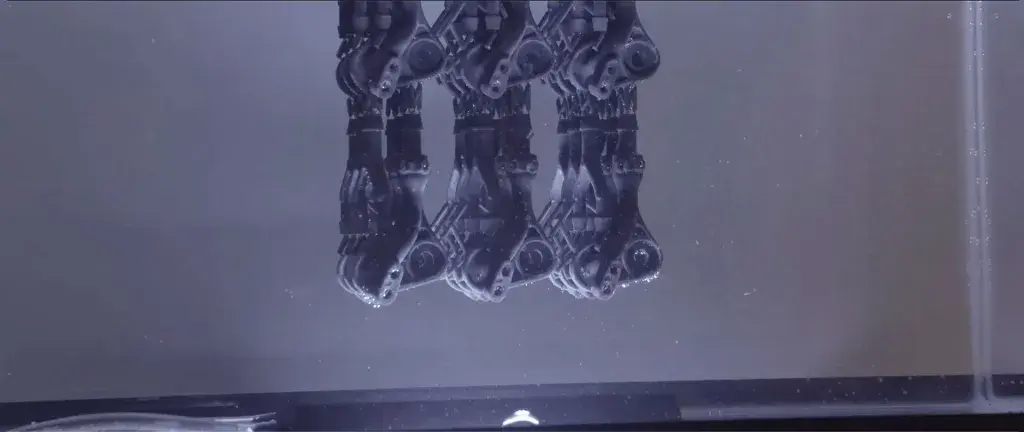

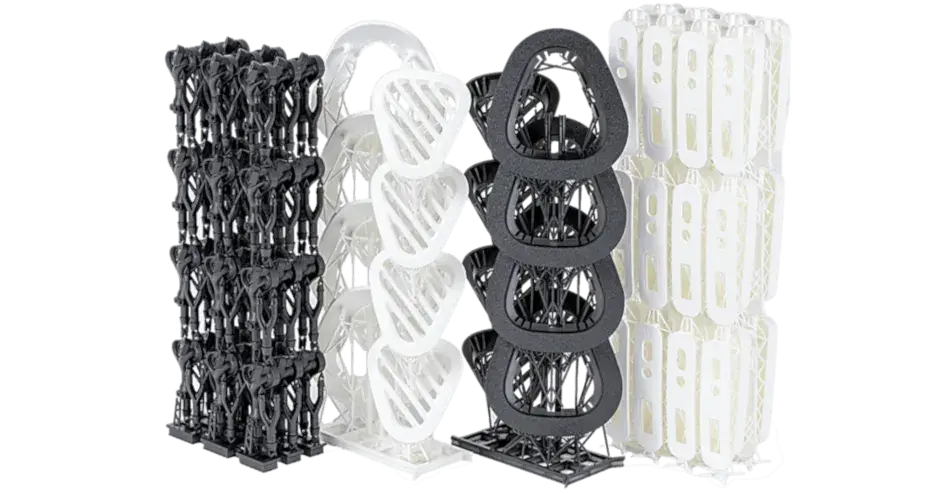

The superior isotropic nature of 3D Systems' Figure 4 3D printing technology and materials allows for extra degrees of freedom in preparing parts for optimal print quality and print efficiency. As a result, parts do not need to be oriented in a special way to achieve the highest mechanical properties – which means parts can be tightly stacked for maximum space utilization and volume efficiency.

The superior isotropic nature of 3D Systems' Figure 4 3D printing technology and materials allows for extra degrees of freedom in preparing parts for optimal print quality and print efficiency. As a result, parts do not need to be oriented in a special way to achieve the highest mechanical properties – which means parts can be tightly stacked for maximum space utilization and volume efficiency.

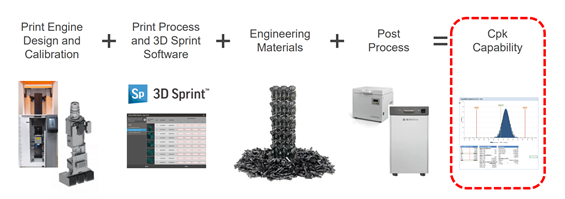

Accuracy and repeatability are also functions of 3D printing technology and hardware. 3D System's Figure 4 technology features datum-driven print engine design and factory-calibrated systems that remove large levels of part-to-part or job-to-job variation. 3D Sprint software offers custom calibration to support the complete end-to-end process for a given material/geometry, which includes the customer setup, printing, cleaning, drying, and post cure.

When combined with production-capable material chemistry and simple post-processing, the result is accuracy, repeatability and cost-effectiveness across high volume plastic part production jobs.

High density part stacking - utilizing 3D Systems’ Figure 4’s printer and 3D Sprint software -- can now enable efficient nesting and a sparse support structure that maximize batch-level printing and minimize manual post-processing times.

"By stacking parts we are able to print in batches of 100, and have reduced the time it takes to prepare a build by 80%. The combination of stacking and production-grade materials makes Figure 4 ready for production."—Gregoire Mercusot, Materials Engineer, ADDLAB, Decathlon

Ultra-fast and affordable for same day prototyping and low-volume production

White plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength

Black plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength.