Digital Manufacturing Using 3D Printed QuickCast® Patterns

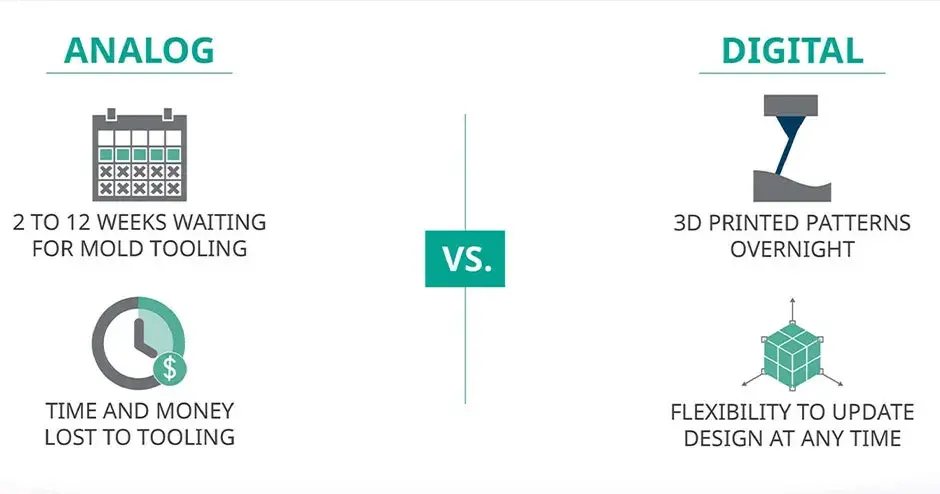

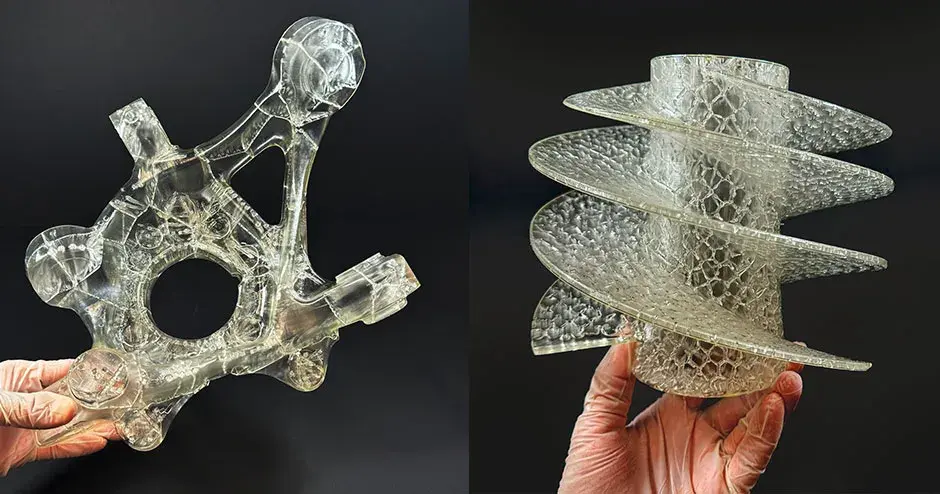

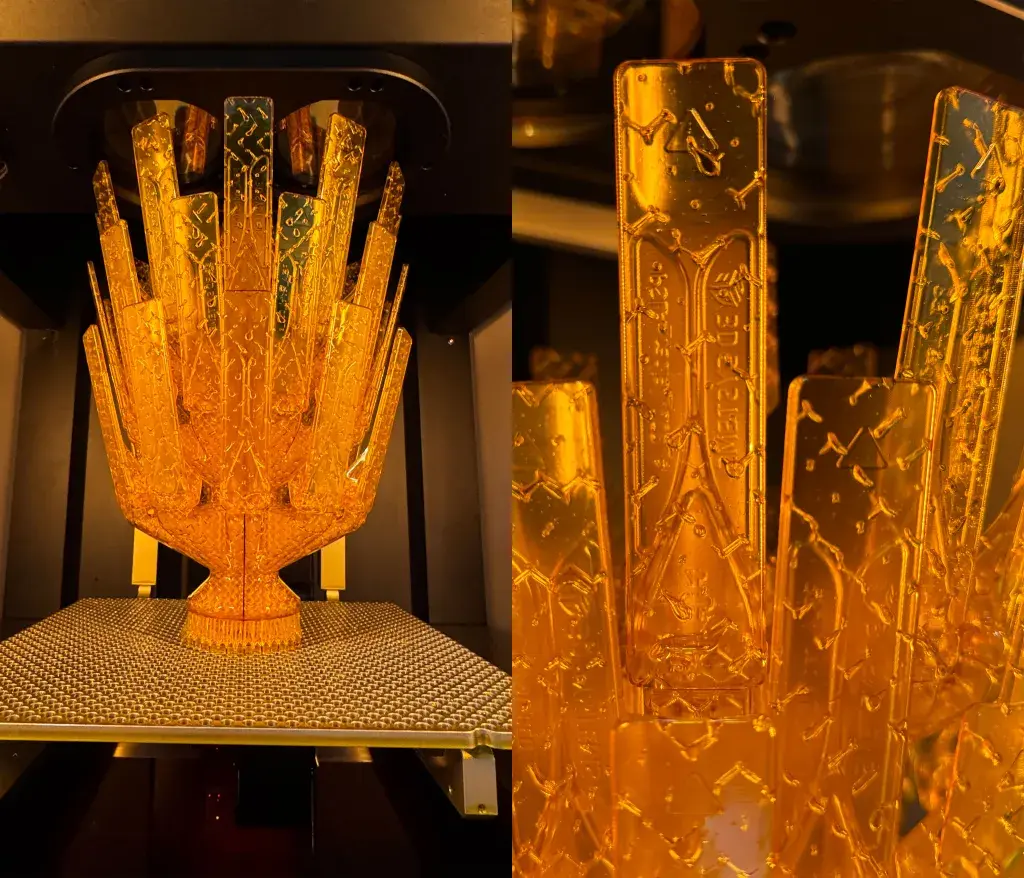

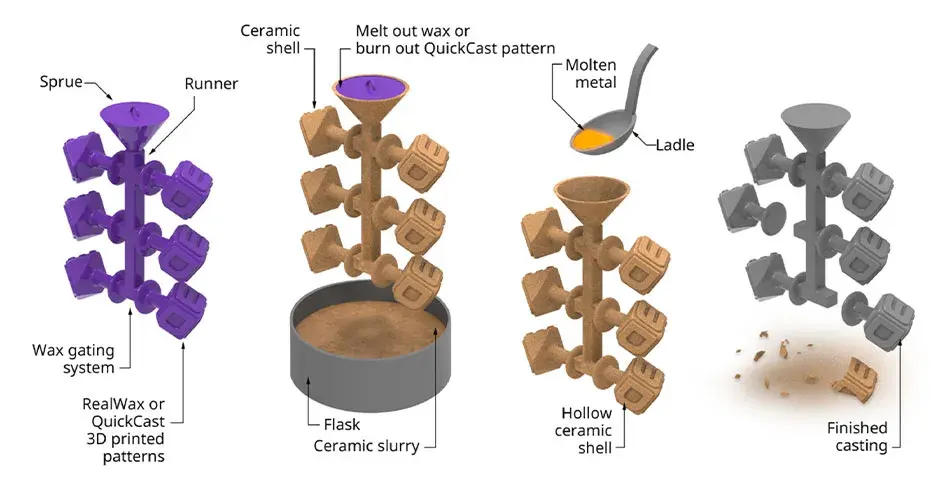

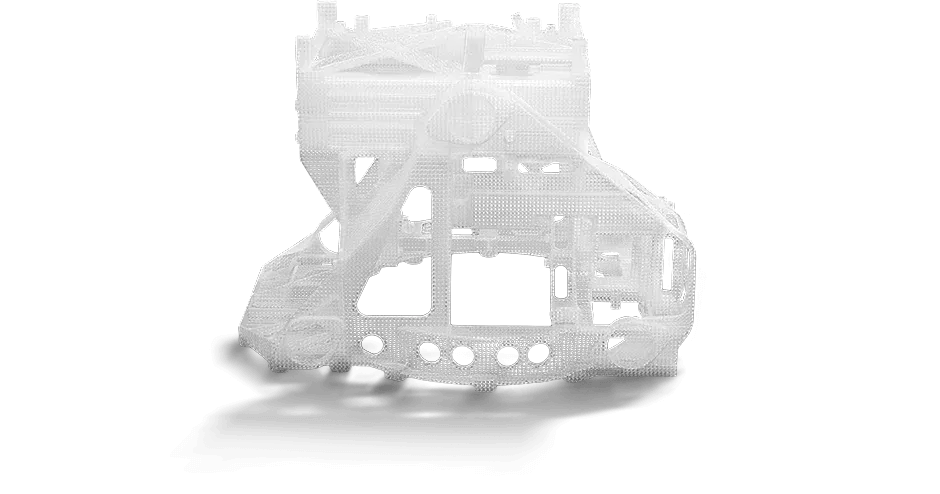

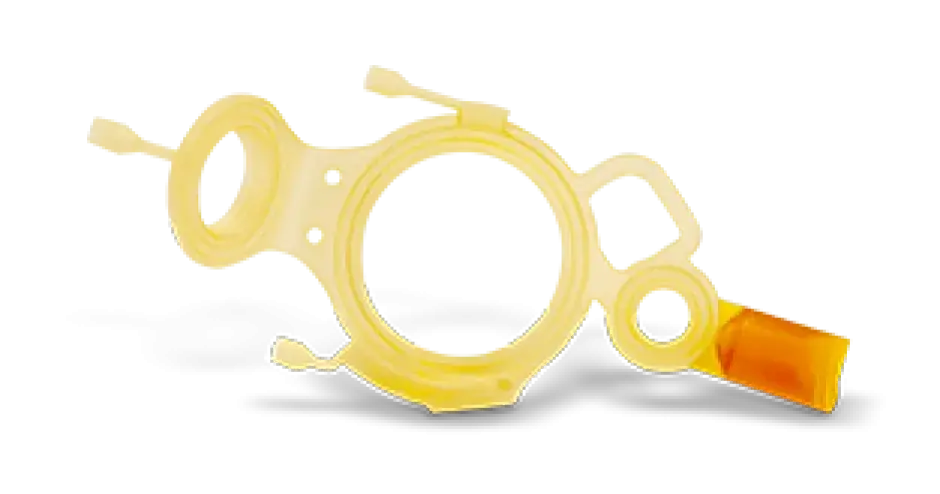

3D Systems QuickCast solution is a digital manufacturing method for producing investment casting patterns. Using advanced software, stereolithography (SLA) or projection-based SLA (PSLA) 3D printing technology and materials, the resulting lightweight, hollow casting patterns are strong enough to resist deformation during the shelling part of the investment casting process. Though durable, these printed patterns successfully collapse under their own expansion to allow for complete drainage and burn out with virtually no ash residue. The result is fast production of high-quality patterns that are easy to handle and integrate into investment casting workflows. With QuickCast patterns, you can deliver easier to cast, complex patterns in hours or days – and eliminate the costs of tooling.

Supporting Your Business Growth and Profitability with Industry Expertise

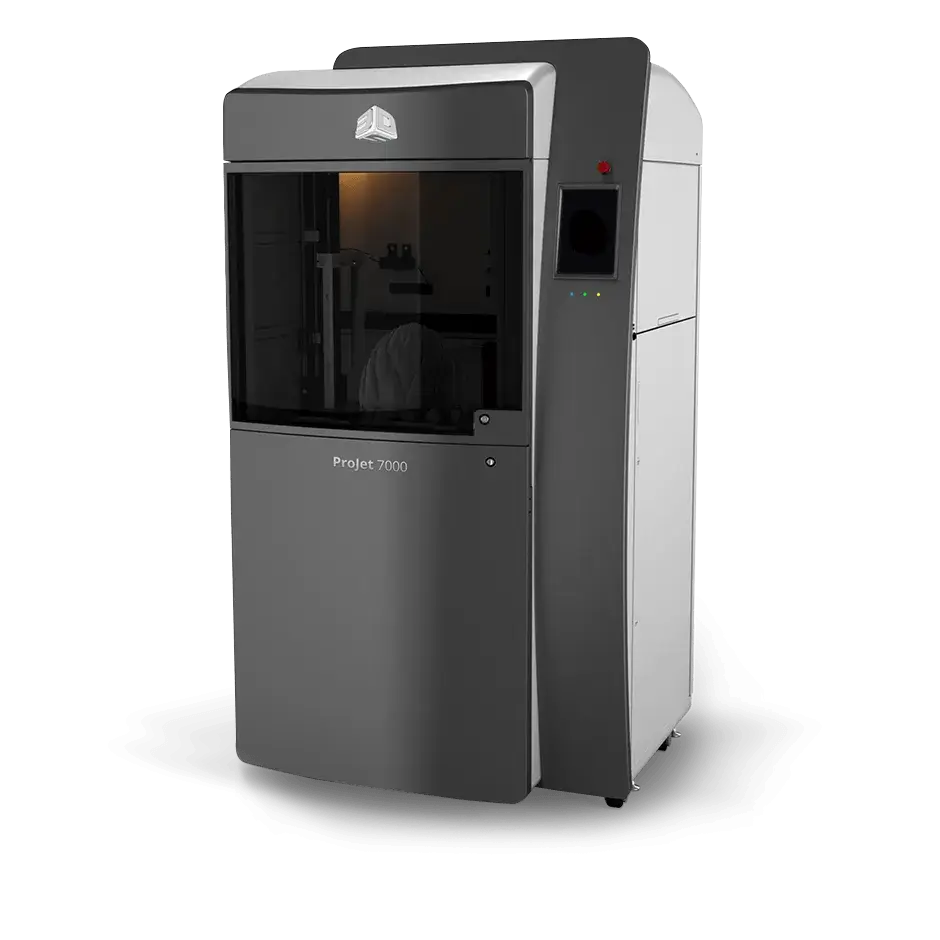

3D Systems 3D Printers and Materials

Our MJP and SLA 3D printers and materials deliver exceptional value, part accuracy, fast speed and production-grade casting patterns. Explore the options below to find the printer and material that's right for you.