Unmatched Turnaround Time

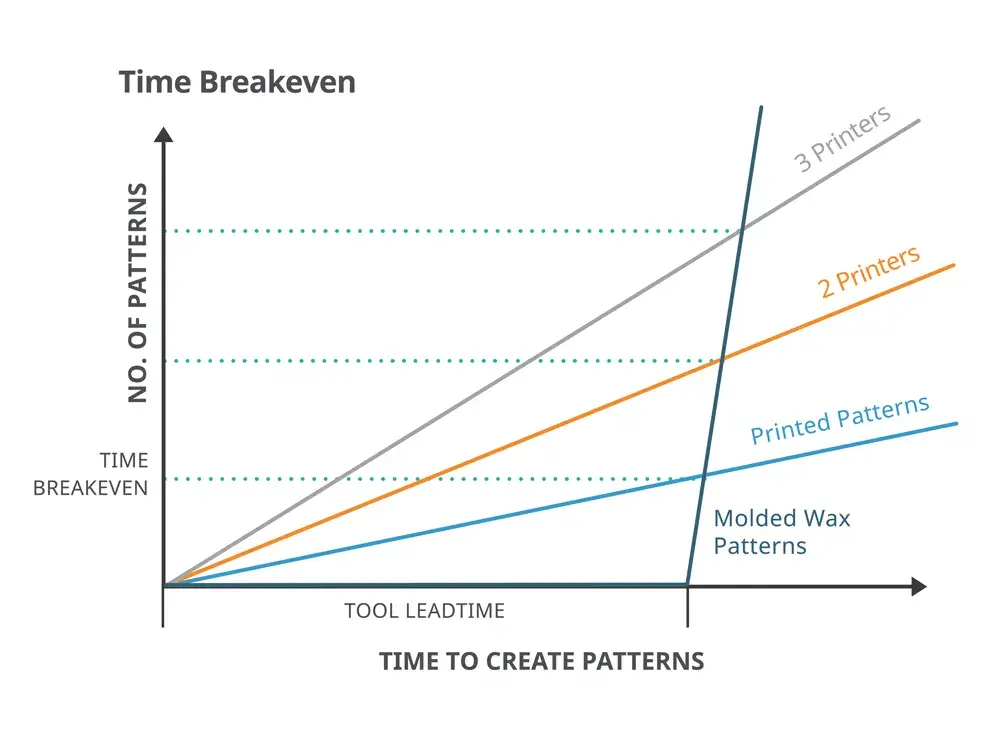

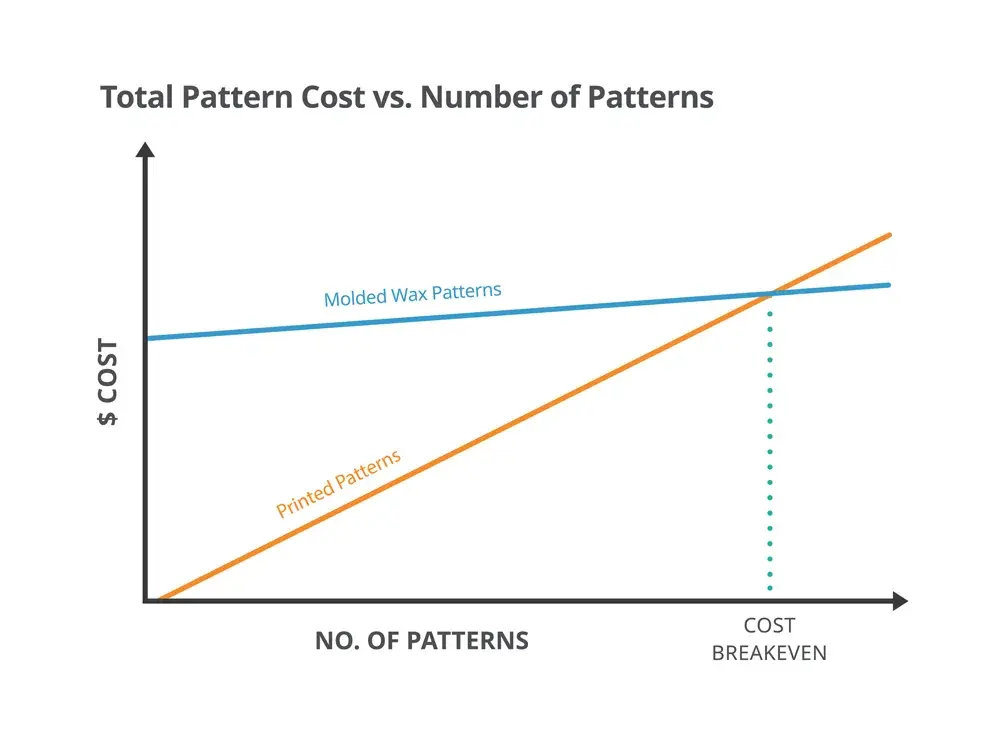

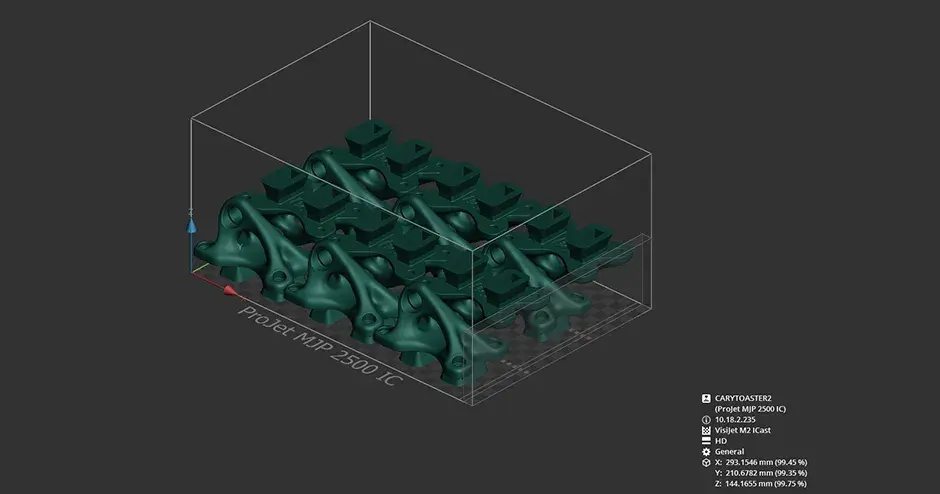

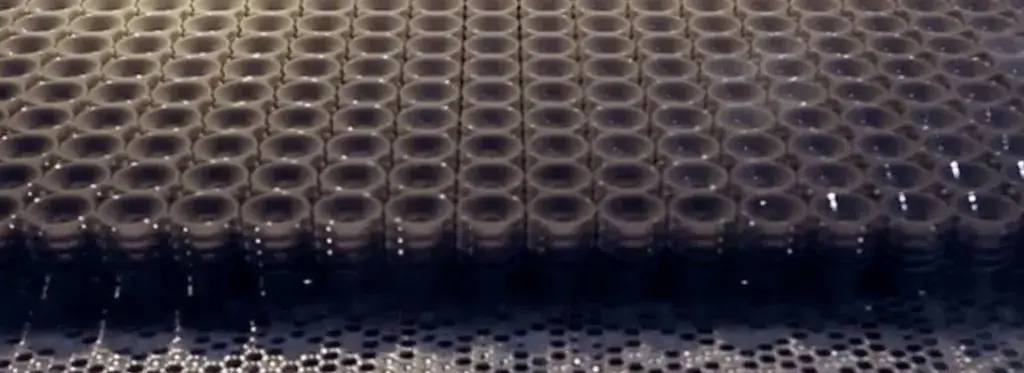

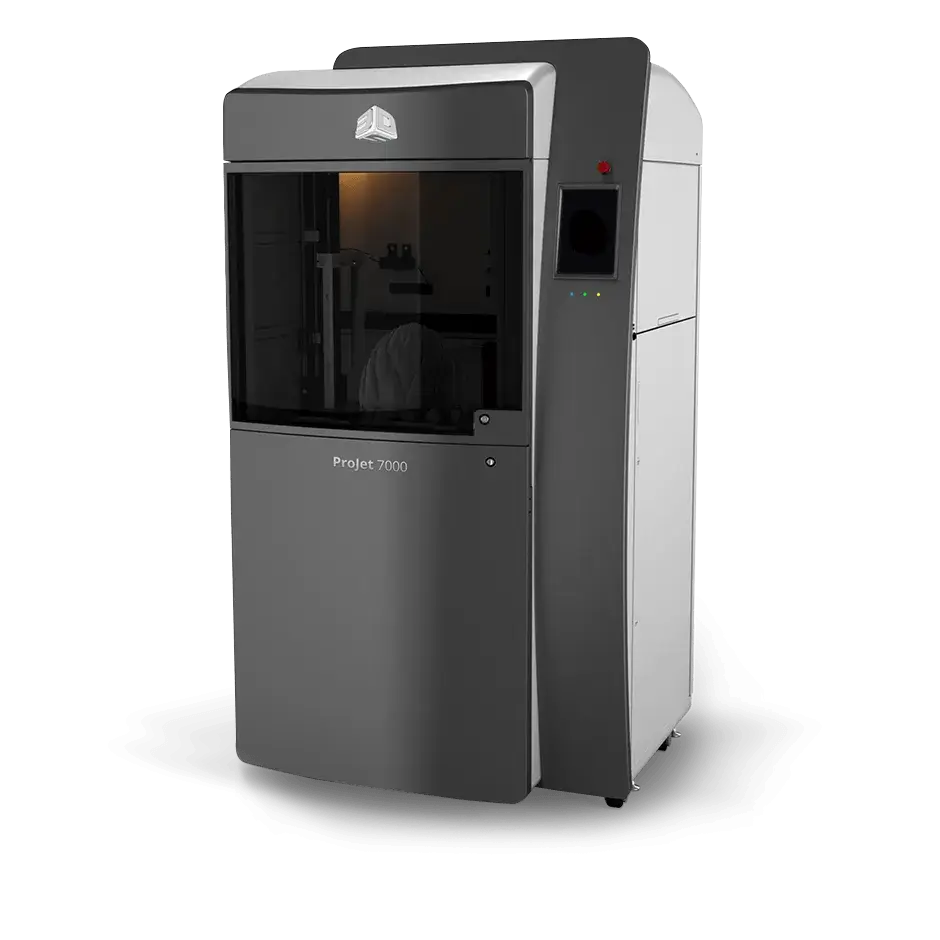

Save weeks on wax pattern production with tool-less RealWax™ MultiJet Printing and accelerate time-to-market. The ProJet® MJP 2500 IC enables a digital workflow with direct wax pattern printing, increasing productivity and enabling fast time-to-part for premium service delivery to customers. With fast wax pattern production, short cycle times capability and 24/7 operation, you can rely on the ProJet MJP 2500 IC output and improved casting room efficiency.