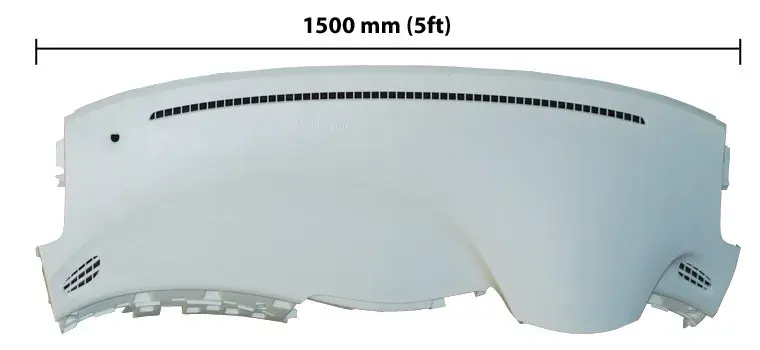

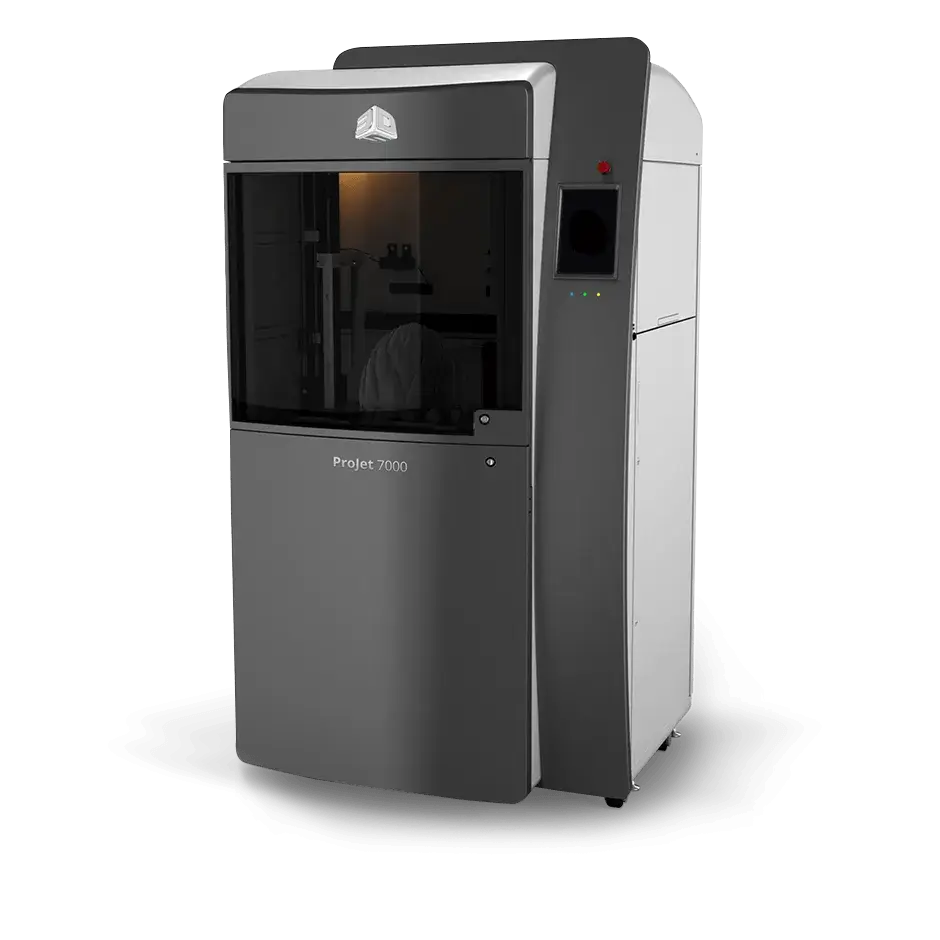

Strong Large Parts in One Single Piece

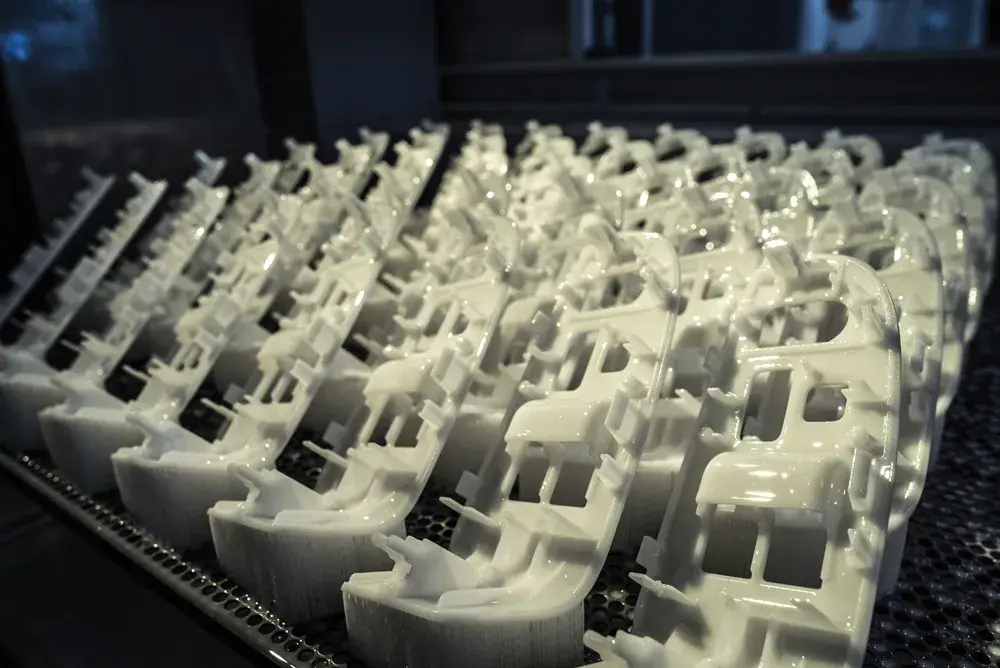

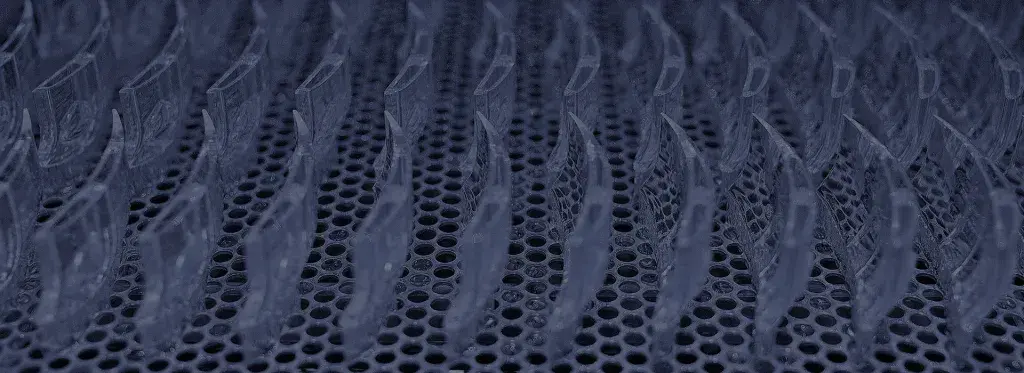

Building large parts up 1500 mm in length in one piece increases part strength, as attachment points always present a weakness in a part. Building the part in one piece also frees additional resources that would be occupied with the assembly of the different segments. Use this feature to build prototype dashboards, middle consoles or stable and light extra-large QuickCast® metal casting patterns. The broad spectrum of Accura® SLA resins is developed for 3D Systems Stereolithography printers to generate the consistency and mechanical properties required for each customer application.