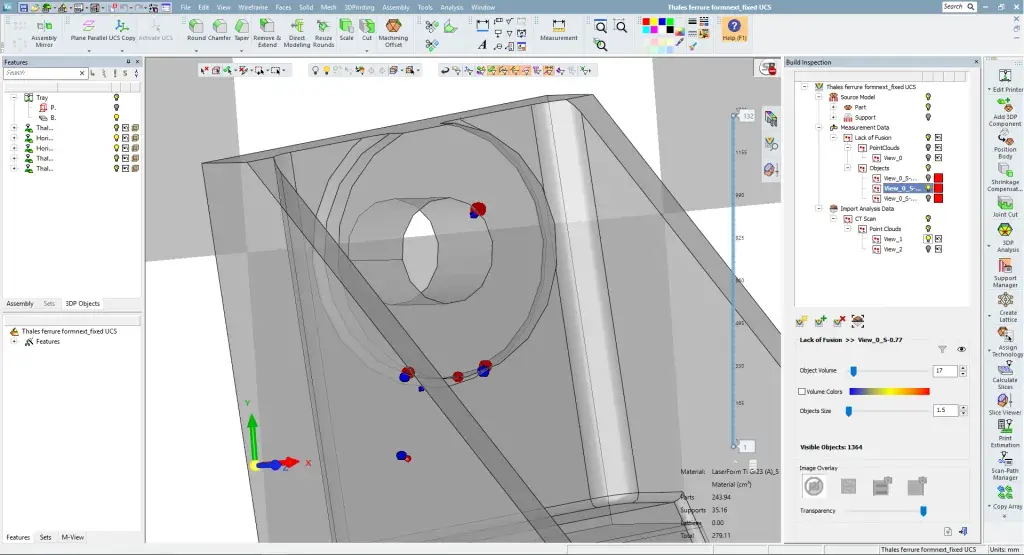

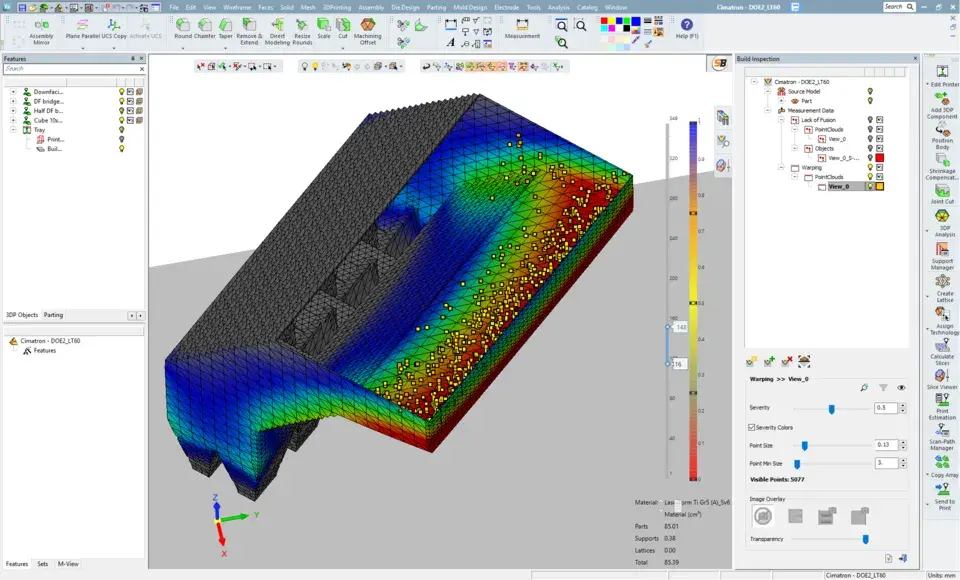

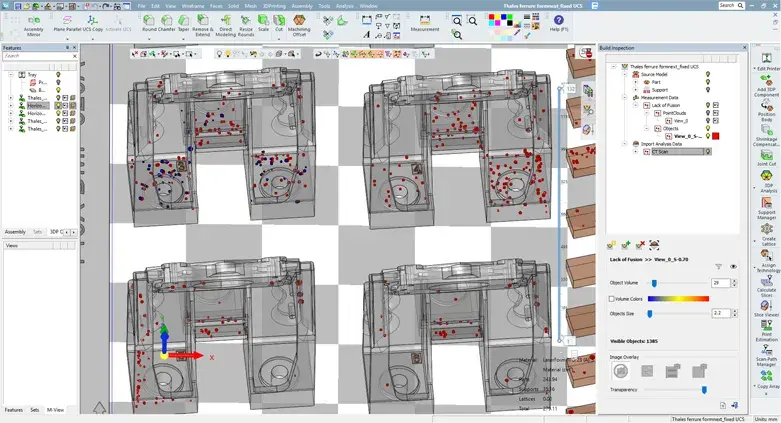

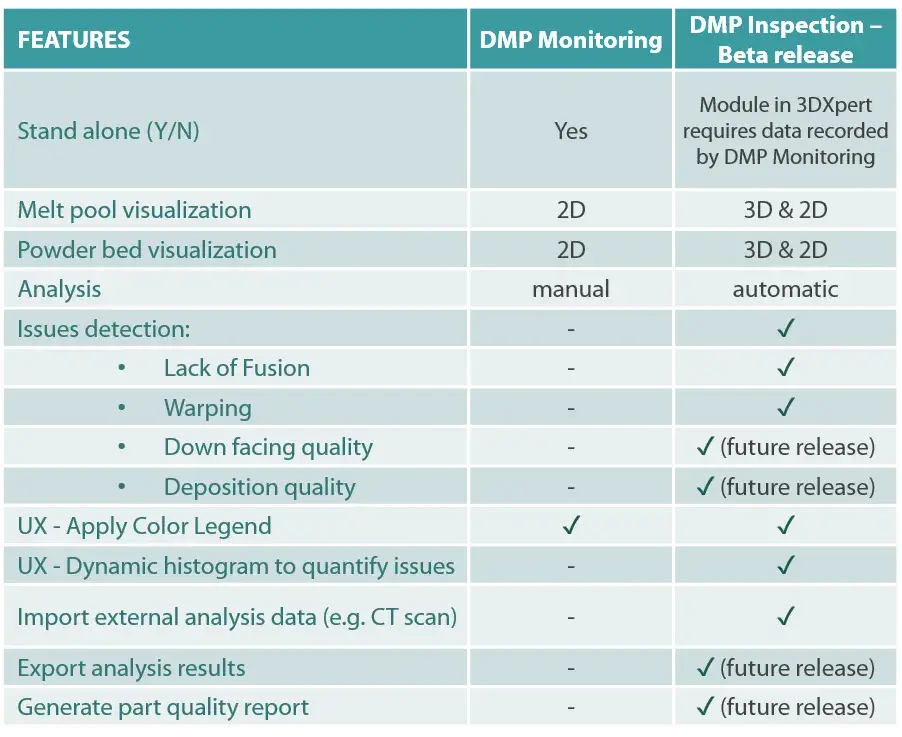

Industry First: Proven Correlation with CT Scan Results

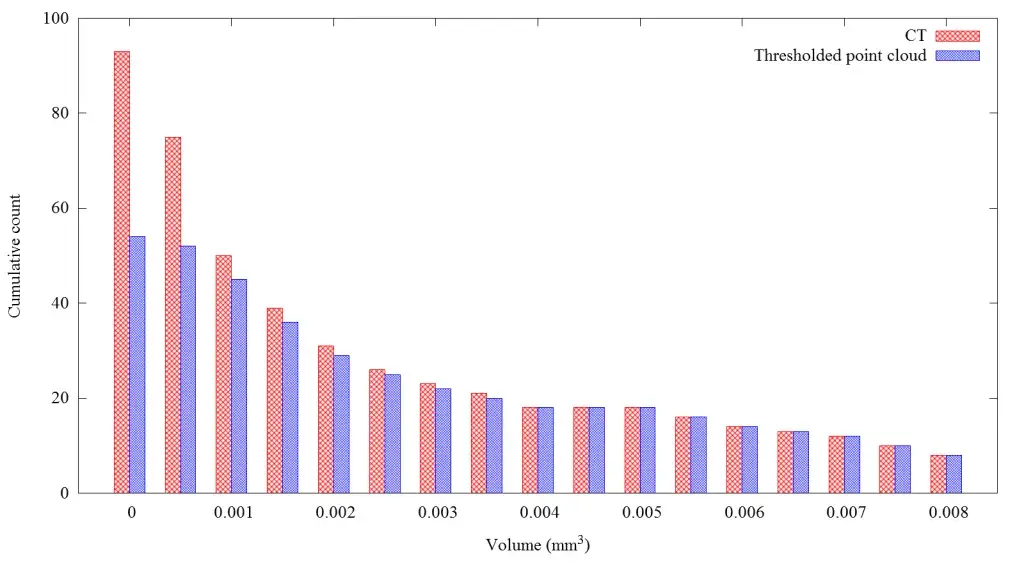

Our team of material and process scientists and engineers developed algorithms that show a high level of correlation with the results from CT Scans, allowing an automated, post-build detection of incidents. In a study a 100% correlation of DMP Inspection analysis results with lack of fusion (LoF) found in CT scan data for defects > 200 μm was verified for a representative test variety of parts in LaserForm Ti Gr23 (A) and Maraging Steel (A) printed on DMP 320 metal 3D printer.