“Even several years ago, metal 3D printing was the way to go in terms of productivity, quality and economics. Just imagine how things have improved since then.” Michal Hermanek, founder, MicroDent

Michal Hermanek, founder and owner of MicroDent, the largest dental lab and dental CAD/CAM services supplier in the Czech and Slovakia regions, believes that 3D Systems’ metal 3D printers allowed his company to grow faster than he could ever have anticipated.

Five years ago, Hermanek founded his dental businesses based on joining two worlds: traditional dentistry and digital solutions. As a tech-savvy graduate and member of a family of dentists, he immediately saw the potential between the developing dental CAD software solutions and scanning. Soon after, the idea of 3D printing became a target for him and his teams. As the company grew, Hermaneck started researching direct metal sintering (DMS) systems.

Having created a small 3D dental bridge model, Hermanek sent the file to several 3Dprinting vendors to create a test part and then assessed the results.Of the 3D printer models he assessed, one stood out. “The sheer qualityof the part created on the ProX™ 100 Direct Metal Printing (DMP) dental system from 3D Systems meant that the part didn’t twist and deform, and also stood up to repeated firing,” stated Hermanek. “The accuracy and the price of the system was also a huge factor in choosing the ProX 100.”

The ProX Direct Metal Sintering (DMS) systems from 3D Systems work using a range of metal and ceramic materials in powder form. Lasers heat specific areas of the powder during the build, working to the definition of the 3D shape, and are so precise that edges can be as small as 150 microns thick. These machines deliver very dense parts that are as strong, if not stronger, than milled and cast parts.

The majority of MicroDent's work is creating dental bridges that will be affixed in a patient’s mouth as a replacement for missing teeth. These bridges have to be highly accurate and resistant to deformation. The team at the lab receives 3D scan data of a patient’s mouth and processes the data to create a design of the pontic (the replacement for a missing tooth) and the two crowns on either side of the pontic, which affix over remaining teeth as an anchor. With small parts such as teeth, and to ensure a comfortable perfect fit, these designs are highly accurate and need to be manufactured very precisely.

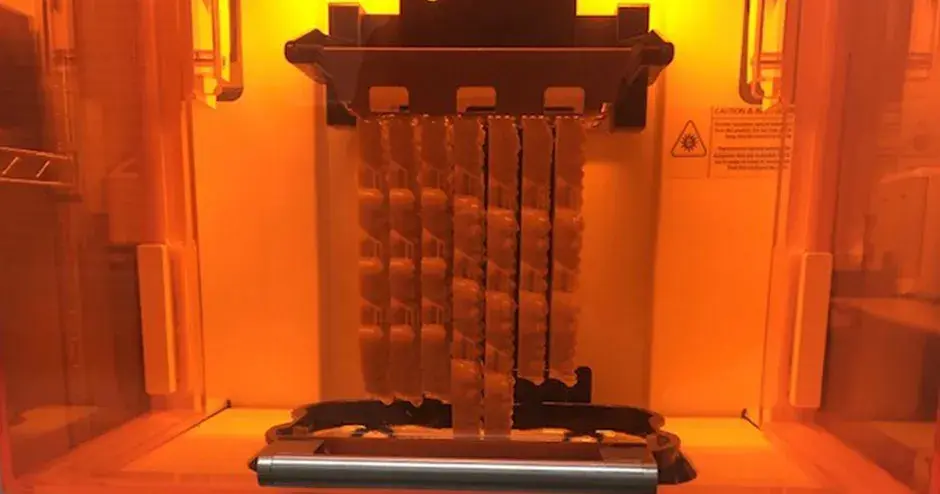

Once the design is ready, the data is uploaded to the printer, which can build as many as 115 elements in either metal or ceramic in a single build. As the ProX 100 is a fast system, the dental elements are completed in a few hours and are ready to be removed. Technicians carefully remove supports, buff the surface finish and prepare the elements for a three-hour fire.

"The results are fantastic," stated Hermanek. "The laser sintering process means that the parts are often created with a range of different temperatures across the build, and the final firing removes any stress points that may have formed. But your part has to be initially robust enough to stand up to the high heat, and this is true of the ProX DMS parts from 3D Systems."

With revenues currently at about €20M, MicroDent has seen rapid growth and rapid profit since it started

"With the quick turnaround we deliver using direct metal sintering, we have also built a reputation for high quality and attention to detail that pleases our dental customers,” says Hermanek. “We own about 90% of the dental laser sintering market in our region, and we plan to keep building with the ProX from 3D Systems."