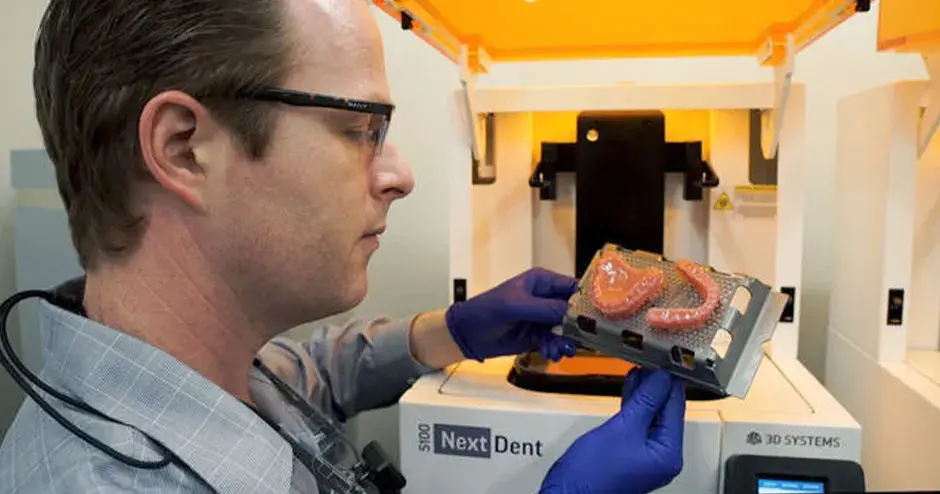

Hybrid Technologies is a small dental laboratory in Orlando, Florida, that specializes in highly esthetic multiple unit implant restorations. Since incorporating 3D Systems’ NextDent™ 5100 dental 3D printer, owner Matt Mills reports “absolutely nonstop” use that has generated new business opportunities for his lab.

Cost-effective 3D printing with wide material choice

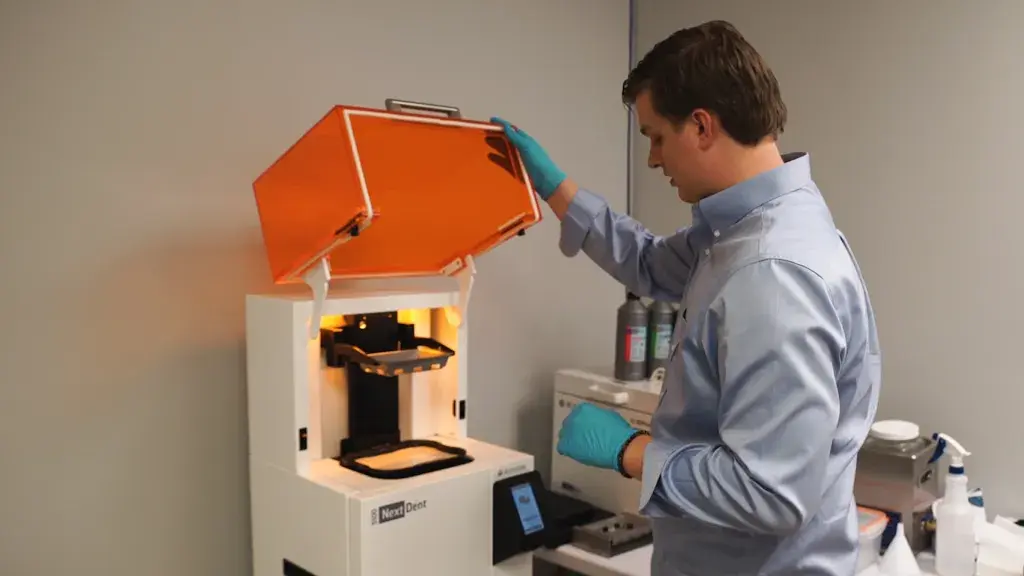

Mills has extensive professional experience with dental 3D printers, so when it came time to choose the right solution to bring in-house, he knew what to look for. As a small lab owner, pricing and capability were his top concerns. Of the options he researched, some were too expensive to consider, and others had recurring costs beyond the materials used.

“Cost was the first thing that drew me towards the NextDent 5100, followed by the breadth of materials,” Mills says. “The fact that I can own this printer rather than lease it makes it a better value, and the fact that resins are the only consumable is a big plus to keep my recurring costs low.” In terms of addressable indications, Mills says 3D Systems’ NextDent resins cover every category his lab will ever need to print.

Application versatility, from 3D printed temporaries and palatal jigs to white digital wax ups

3D Systems’ NextDent material portfolio includes 30 unique biocompatible and CE-certified materials to address a broad range of clinical needs. Hybrid Technologies takes advantage of several of these materials, including NextDent C&B MFH, NextDent Model 2.0 and NextDent Tray.

3D printed temporaries improve accuracy, shorten appointment times

In addition to providing high quality lab work for final dental restorations, Hybrid Technologies offers esthetic 3D printed temporaries (shell temps) for in-mouth wear while the final restoration is being made. Hybrid Technologies works with dentists on esthetically demanding cases, in which the temporaries are extremely important because they function as a communication tool between the patient, the doctor, and the lab. “Using NextDent MFH material for shell temps looks ten times better than anything you can mill, and it's so much more cost-effective,” says Mills.

Whereas the conventional process for temporization involves a considerable amount of chair-side manipulation by the dentist, a digital workflow with the NextDent 5100 improves the process for both the dentist and patient. Mills says the dentists he works with like the shell temp service because it allows them to be highly accurate with shorter appointment times. Hybrid Technologies also polishes and textures the NextDent prints for highly attractive results, which means the patients are happy with their smile throughout treatment.

3D printed palatal jigs indispensable to full-arch restorations

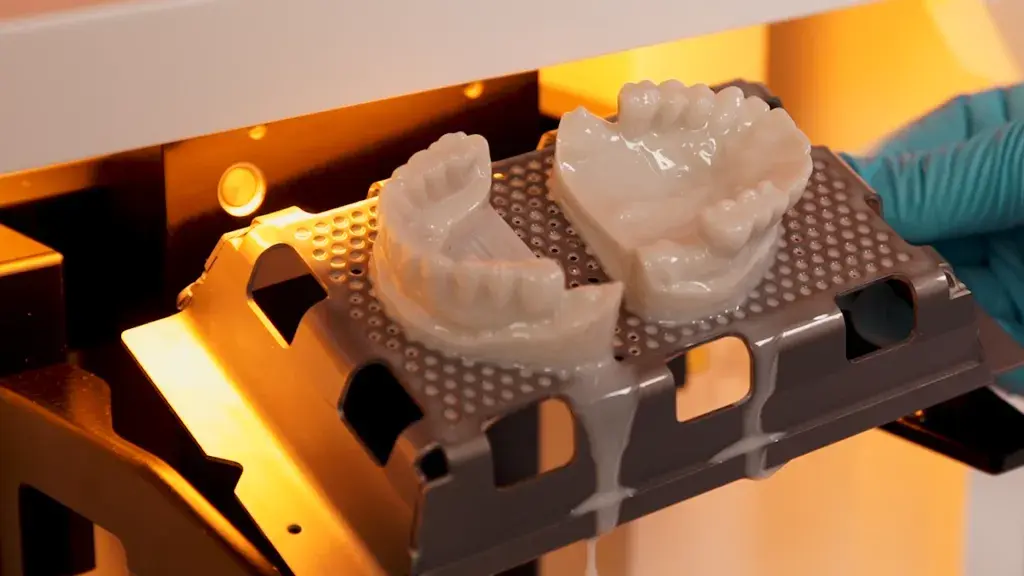

Without teeth for the dentist to index the placement of a temporary or final restoration, full arch edentulous cases require a palatal jig. The NextDent 5100 has made it possible for Hybrid Technologies to offer 3D printed palatal jigs for full-arch restorations as a cost-efficient alternative to conventional palatal jigs.

Conventional palatal jigs are milled using a special milling puck that is taller than average to accommodate the height of the device. The material costs and wear and tear to the milling machine of traditional palatal jigs made these tools too expensive for Hybrid Technologies to offer conventionally. However, Mills says his lab is now able to 3D print palatal jigs using the NextDent 5100. “3D printing versus milling is definitely a positive in more than one area,” says Mills. “The cost savings on materials is huge, but by 3D printing you are also able to save the integrity of your milling machine for materials like zirconia.”

Using a two-stage build process, Hybrid Technologies prints a kind of bite splint that shows where the shell temps will fit. The anterior teeth are prepped in the first stage, and the posterior teeth are prepped in the second. This allows a constant frame of reference for positioning. “When you break up the shell temps into sections like that, placing them in the mouth becomes very accurate and esthetic,” says Mills. “Providing accurate temporaries that are precisely placed in the mouth increases the predictability of the final outcome, along with the patient’s satisfaction in the final restorations.”

Mills says his business has been able to grow tremendously with this new offering. “Offering shell temps with a palatal jig is probably one of the biggest and most profitable parts of my lab,” Mills says. “That workflow has really opened a lot of doors for me.”

White digital wax ups help doctors sell treatment

Mills reports enthusiastic feedback on the esthetic quality of NextDent prints across indications, including the digital wax ups he is able to 3D print in a true white color using NextDent Model 2.0 material. “A lot of companies offer ivory, peach, or gray materials for digital wax ups, but NextDent Model 2.0 is an actual white material, and that’s huge,” Mills says.

Access to white dental materials has been a game-changer for the doctors Mills works with who need to give their patients a preview of their anticipated treatment. “Patients need to be able to trust their doctor with what they are going to do with their smile, and when they’re looking at peach-colored teeth, the patient starts second-guessing,” Mills says. Since offering digital wax ups with NextDent Model 2.0, Mills has been able to help his doctors sell more cases with white and shiny teeth that represent the smile makeover patients want to see.

Speed of printing enables same-day services

Hybrid Technologies works with several doctors who also have the NextDent 5100 in-house, and supports their workflow with dental design services. Together, the dental lab and dental offices coordinate to deliver enhanced and accelerated patient care.

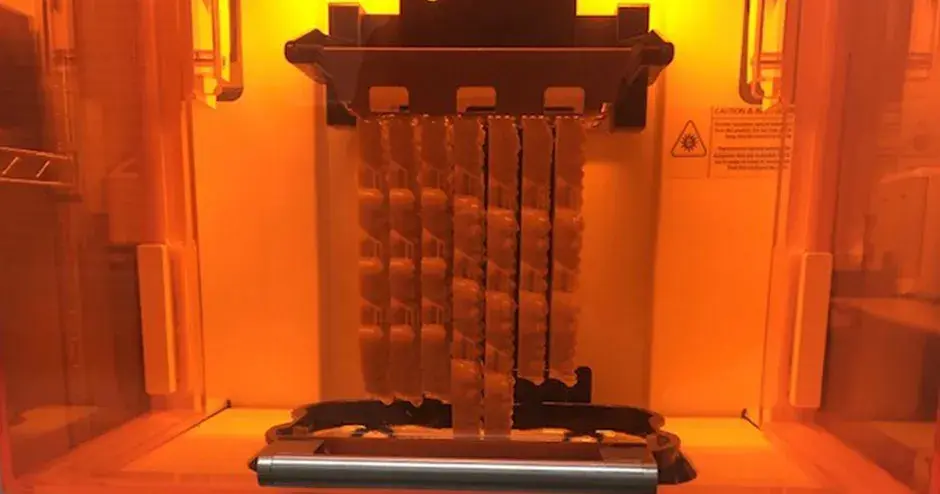

The dentist books Hybrid Technologies’ time to match the patient’s appointment, and while the patient is in the chair for treatment, the dentist sends the patient’s intraoral scan to the lab for concurrent design work. Hybrid Technologies completes the work and sends back a file for 3D printing within the appointment window. The dentist 3D prints the file in-house and sends the patient home with an esthetic result. “The NextDent 5100 can print a full arch in 30 minutes, which means massive improvements to same-day dentistry,” says Mills.

According to Mills, the print speed of the NextDent 5100 is a tremendous advantage for his lab work as well: “On any other printer, I’d maybe get two prints done in a day, run another overnight, and hope to catch up in the morning. With the NextDent 5100, I can easily get 10 to 12 prints done in a day, in between my other work.”

Mills reports a user-friendly experience operating the NextDent 5100. In addition to excellent functionality of the included 3D Sprint® software, he says part and support removal are quick and easy. “3D Sprint is awesome,” Mills says. “It’s much better than other nesting software I’ve used, and the process to get parts off the build plate is much improved over other printers as well. I haven’t broken a single model, and the Smart Supports pluck right off.”