Evaluating AM Production Grade Resins for Figure 4

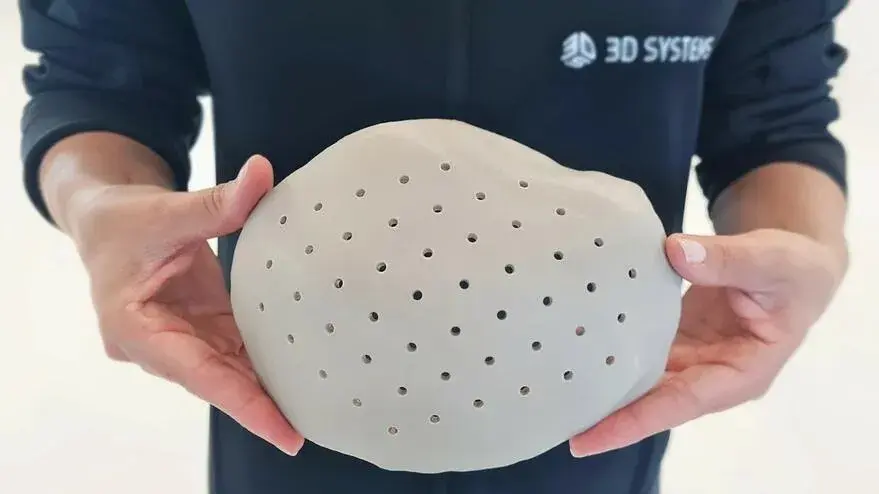

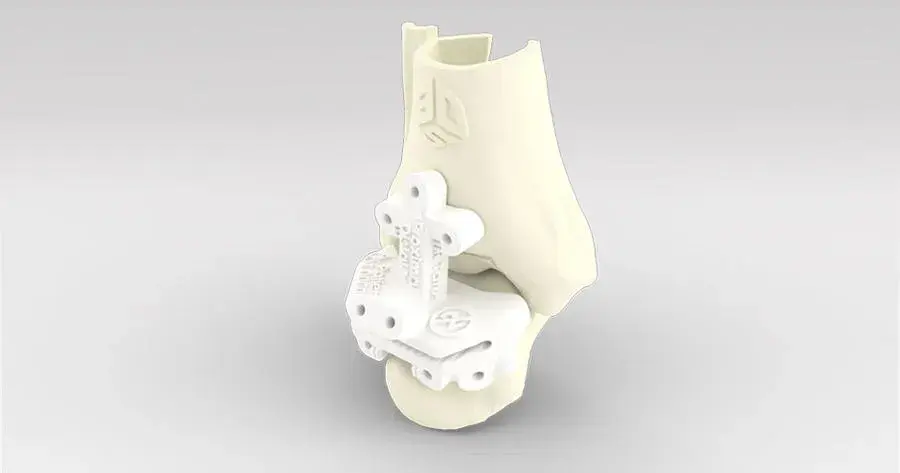

With recent process advancements, additive manufacturing enables access to parts with production-ready quality, speed, and cost. The only thing left to master is achieving production-grade material properties. With our Figure 4 production-grade resins, the wait is over. Now it is possible to go from prototyping straight to production on the same system for a seamless and efficient workflow. Before you get started, it’s important to identify if the material is right for you.