Key Additive Manufacturing Applications for EV Manufacturing

Explore Our Automotive Expertise

Talk to an Expert

Explore AM Technologies for EV

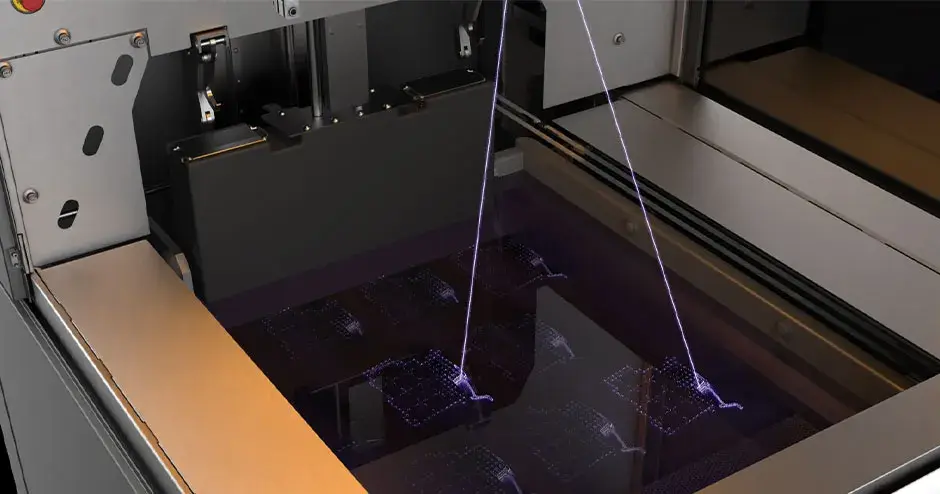

Stereolithography (SLA)

Stereolithography (SLA) is the first commercialized 3D printing technology, invented by 3D Systems' Co-Founder and Chief Technology Officer Chuck Hull in the 1980s.

MultiJet Printing (MJP)

MultiJet Printing (MJP) is an inkjet printing process that uses piezo printhead technology to deposit either photocurable plastic resin or casting wax materials, layer-by-layer.

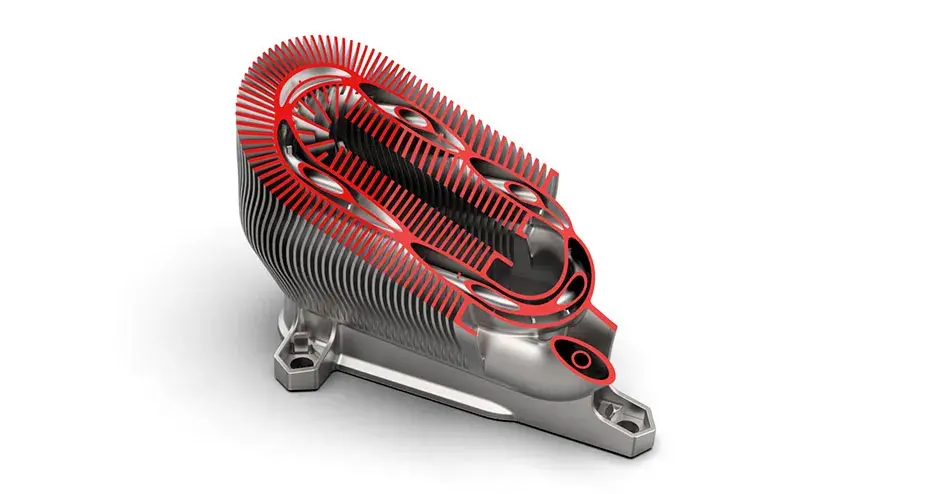

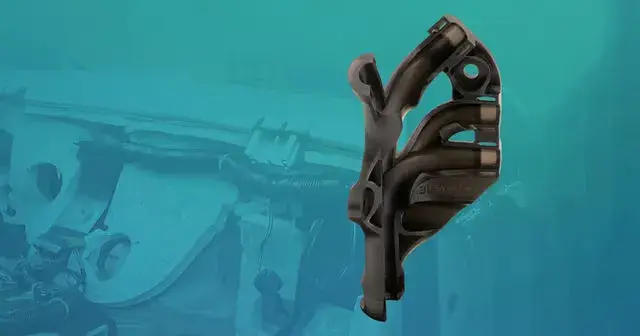

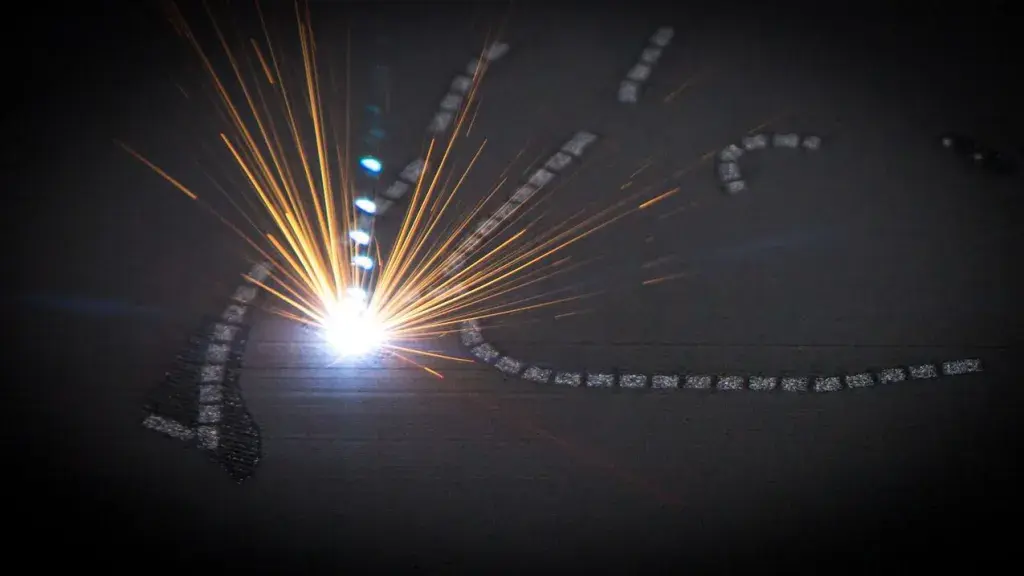

Direct Metal Printing

Direct metal printing (DMP), is an additive manufacturing technology that builds high quality complex metal parts from 3D CAD data. In the machine, a high precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers one after the other.

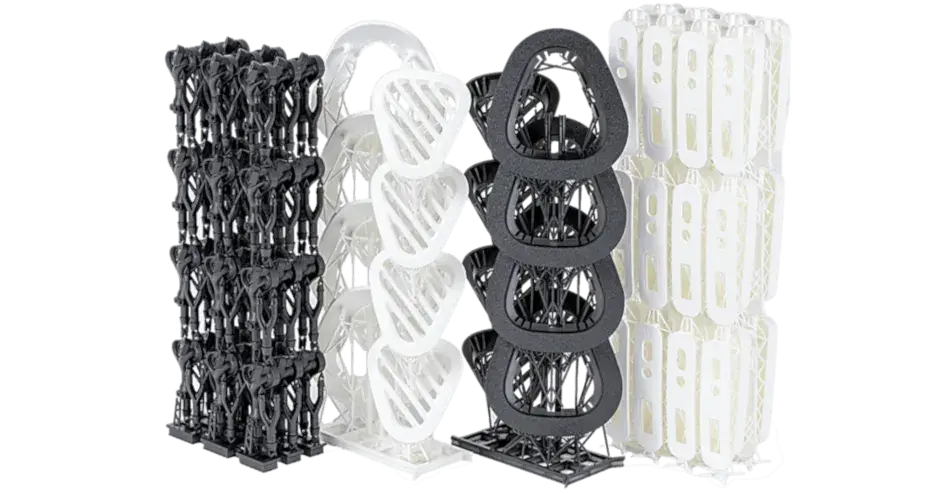

Figure 4

Figure 4® delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powder-based 3D printing technology that uses a laser to fuse material layers into a final part. The laser traces the pattern of each cross section of a 3D design onto a bed of powder. After one layer is built, the build platform lowers and another layer is built on top of the previous layer. This process continues until every layer is built and the part is complete.