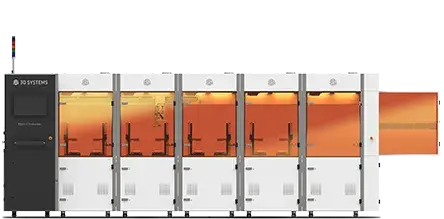

Manufacturing Redefined

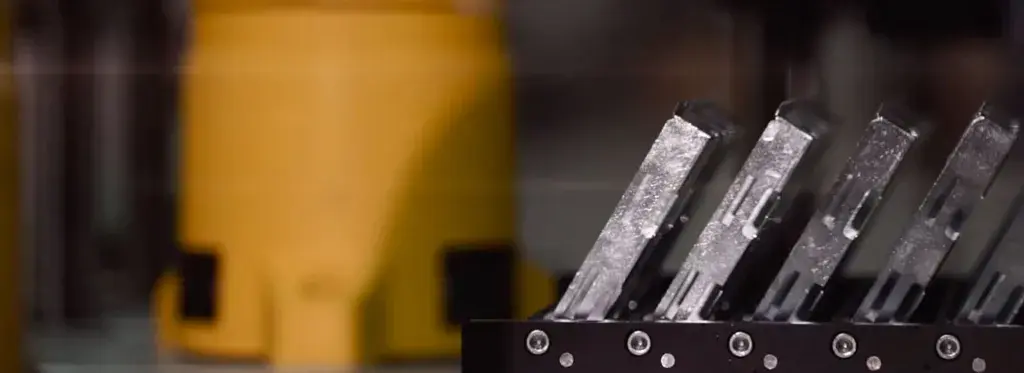

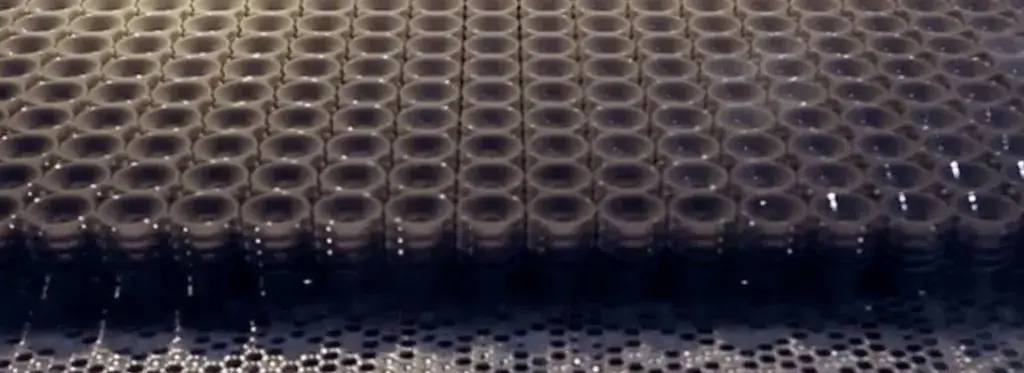

3D Systems Figure 4 makes 3D production a reality—with increased productivity, durability, repeatability and lower total cost of operations (TCO). Figure 4 delivers productivity enabled through speed and automation with real world repeatable, accurate parts with demonstrated Six Sigma performance in a diverse range of robust, production-grade materials.