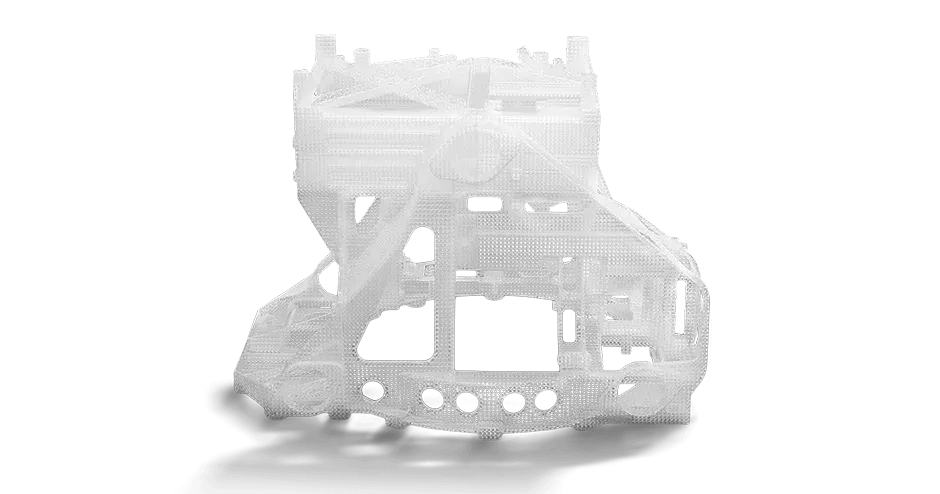

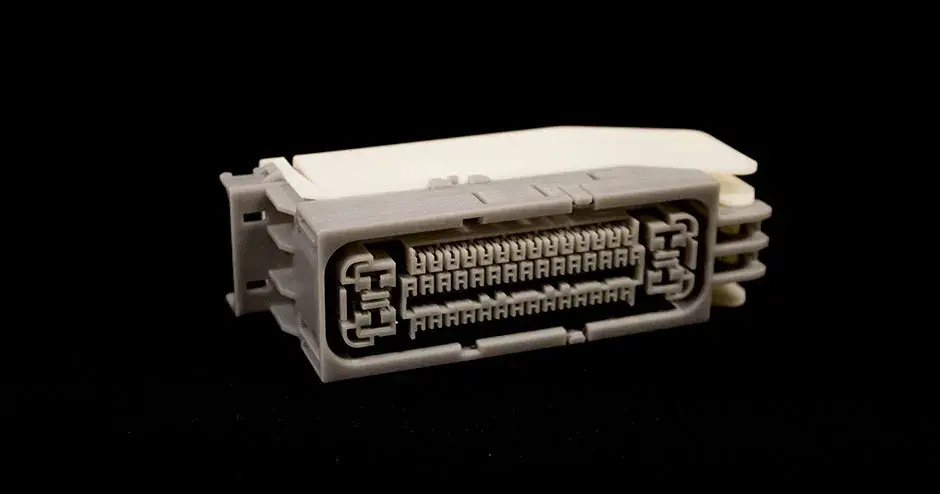

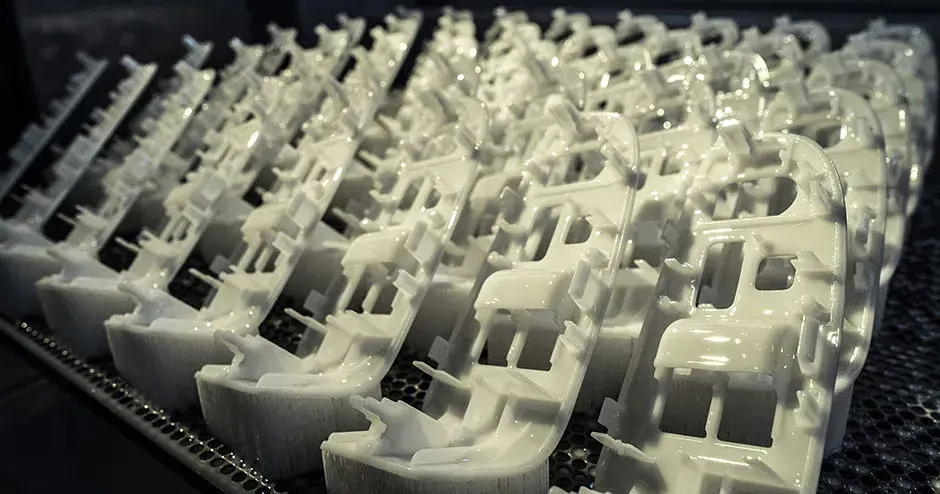

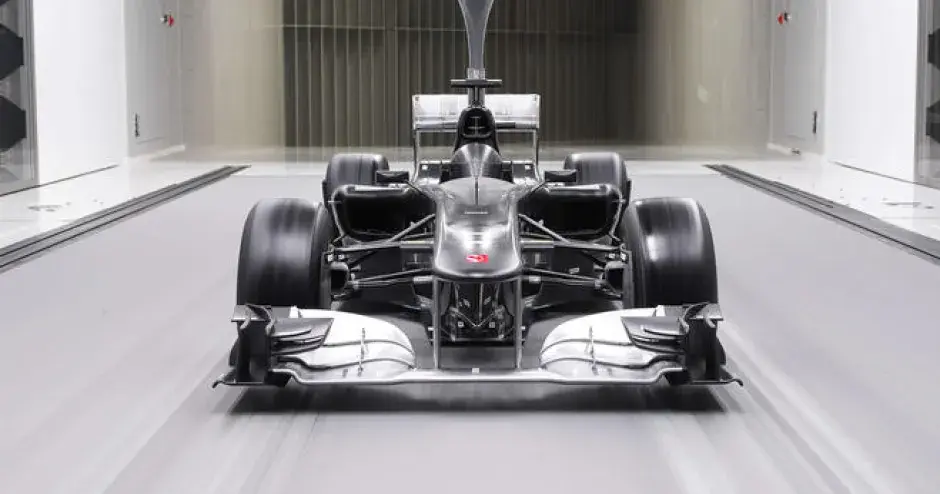

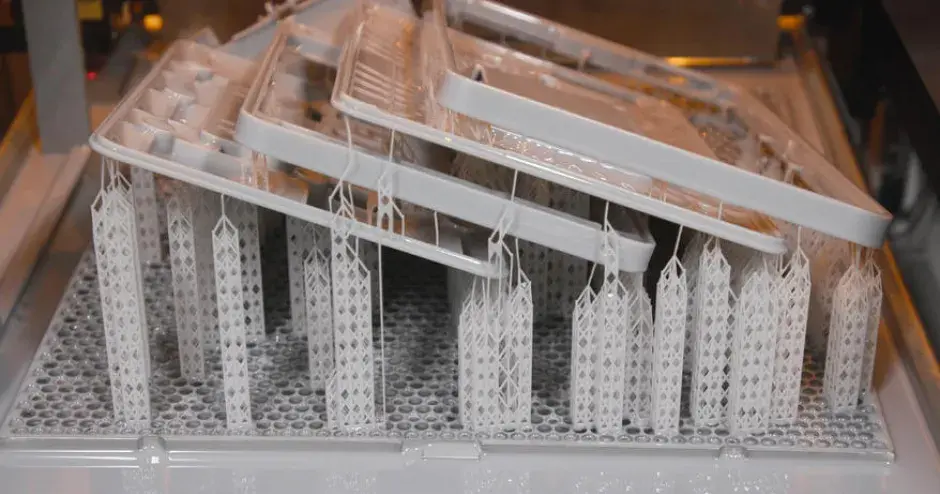

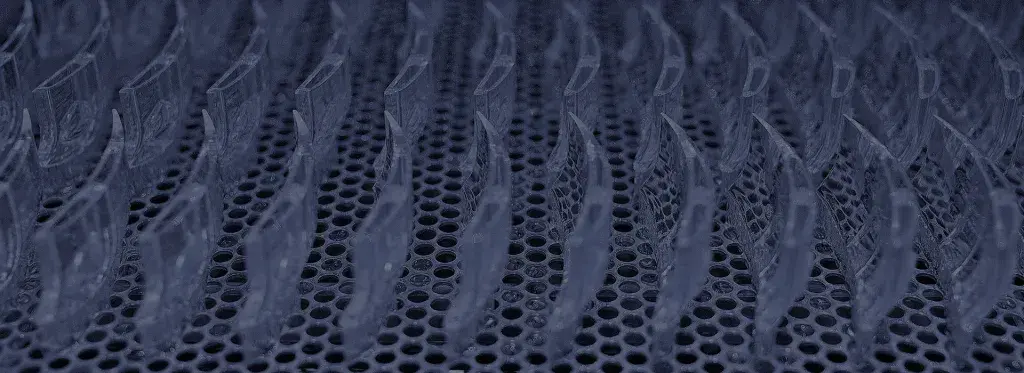

SLA is all about precision and accuracy, so it is often used when form, fit, and assembly are critical. The tolerances on SLA parts are typically less than 0.05 mm, and SLA offers the smoothest surface finish of any additive manufacturing process. With the quality SLA can achieve, it is particularly useful for creating highly precise casting patterns (e.g., for injection molding, casting, and vacuum casting) as well as functional prototypes, presentation models, and form and fit testing. SLA technology is extremely versatile and can be used in any number of areas where precision is paramount.

SLA also offers a speed advantage when you require a variety of functional prototypes or quick access to casting patterns. SLA’s winning combination of speed and precision make it an excellent choice for evaluating prototypes. The accuracy of SLA means your prints are faithful to the final design, allowing you to identify and correct design flaws, collisions, and potential mass-manufacturing hurdles before production begins. SLA provides comparable characteristics to parts normally machined from polypropylene or ABS for low- to mid-volume production, and doesn’t require slow, expensive retooling for customization or required tooling changes. SLA also allows for reduced material costs, as any unused resin remains in the vat, ready for future projects.

Because SLA parts can require support structures, they often require post-processing, which opens opportunities for new part characteristics. SLA parts can be vapor honed, or bead or sand blasted, and can even be electroplated with metal, such as nickel. Electroplating makes SLA parts significantly stronger, and also makes parts electrically conductive and more dimensionally stable in moist environments.