Using the latest in production additive manufacturing and 3D scanning techniques, patterns for the historic vases were produced quickly and cost effectively.

History

Fundidora Morelia (FM) is a family-owned steel foundry with more than 40 years of experience specializing in the casting of ferrous alloys. Proveedora de Servicios y Suministros Industriales (PSSI), was founded in 2016 to serve as a high-tech pattern shop for FM. Together, the companies utilize 3D printers, including a 3D Systems EXT 1070 Titan Pellet 3D printer, CNC routers, 3D laser scanning, CAD modeling and the latest testing techniques to create high-quality patterns and castings.

The small town of Cochuco, located in the state of Michoacan, Mexico, is well known for its history and craftmanship, where local artisans most notably manufacture giant clay pots by hand.

“As a family from Michoacan and as an enterprise based in Morelia, we are very proud of our culture and traditions, and we wanted to make a tribute to our artisans and their renewed arts and crafts,” said Alonso Alvarez of PSSI.

FM and PSSI commissioned a joint effort to reproduce two of the iconic giant vases in cast steel, bridging the industrial and artisanal sectors of the region.

Process

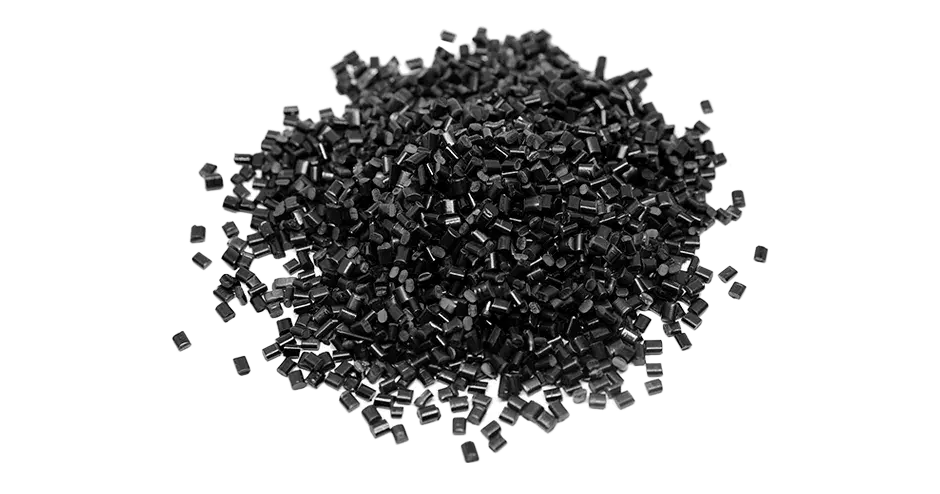

PSSI conducted the reverse engineering process by 3D scanning the original pot and creating 3D-printable CAD models of the cope and drag patterns for casting. PSSI printed the large patterns using pellet extrusion on their EXT 1070 Titan Pellet 3D printer and hand finished the parts with body filler and sanding for a smooth finish.

FM cast the model in steel which they gave a blued finish, and stainless steel which they polished to a striking mirror finish. The time to produce the patterns was cut in half with 3D printing compared to traditional methods of CNC machining the patterns. It took just 1.5 days to create the patterns on the EXT 1070 Titan Pellet. Thanks to the EXT 1070’s lights out manufacturing, labor requirements were also cut in half compared to traditional pattern making methods.