Benefits of Pellet Extrusion

Polymer Pellet Feedstocks

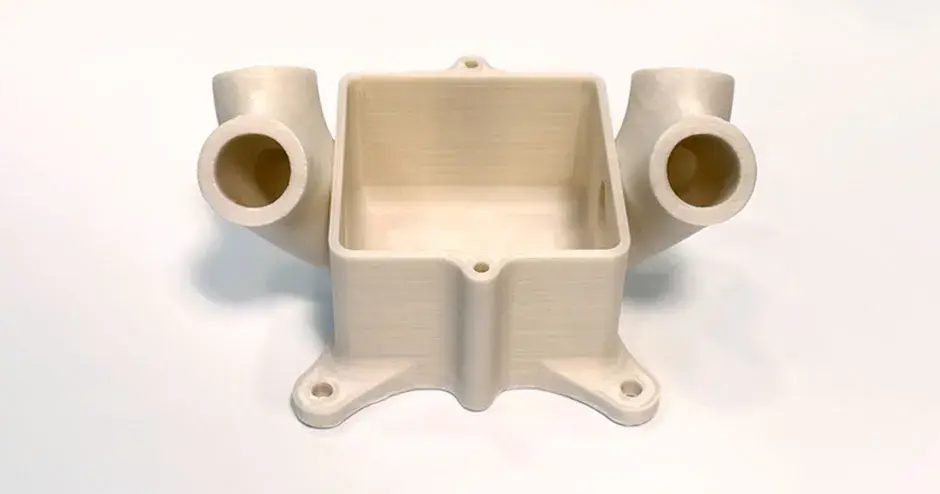

Examples of Pellet Extrusion Production Parts

Through Braskem’s partnership with 3D Systems, we have combined competencies in machine development and polymer design to introduce a unique product to the market. It is our goal to continue to listen to the needs of our clients and evolve our 3D product portfolio to best support the value chain. We look forward to our continued collaboration.—Jason Vagnozzi, Braskem Additive Manufacturing Leader, North America

Printers Compatible with this Material:

EXT 1070 Titan Pellet

3D Systems’ flagship pellet extrusion printer capable of printing medium-to-large format parts, featuring a build volume of 1070mm x 1070mm x 1118mm (42" x 42" x 44").

EXT 1270 Titan Pellet

3D Systems’ largest 3D printer capable of printing full-scale parts up to 6 feet tall with direct pellet-fed 3D printing.

EXT 800 Titan Pellet

Our entry-level industrial pellet extrusion 3D printer with a compact frame that will fit through standard double doors.