We have gained a lot of business with our EXT 1270 Titan Pellet 3D printer. The turnaround time for parts, molds, and formed parts has put us leaps and bounds above our competition.—David Rheinheimer, Duo Form Product Development Manager

THE CHALLENGE

Time, Cost, and Delays in the Production Process

In the competitive thermoformed plastics market, Duo Form continually works to innovate its manufacturing process, shorten lead times, and reduce costs to better serve its customers and win new business. At the same time, maintaining mold quality and durability is key.

Time and cost savings are not the only challenges thermoformers like Duo Form face. They also need to innovate quickly with design iteration and produce full-scale prototypes to avoid delays in the approval and production process.

THE SOLUTION

Producing Molds with AM

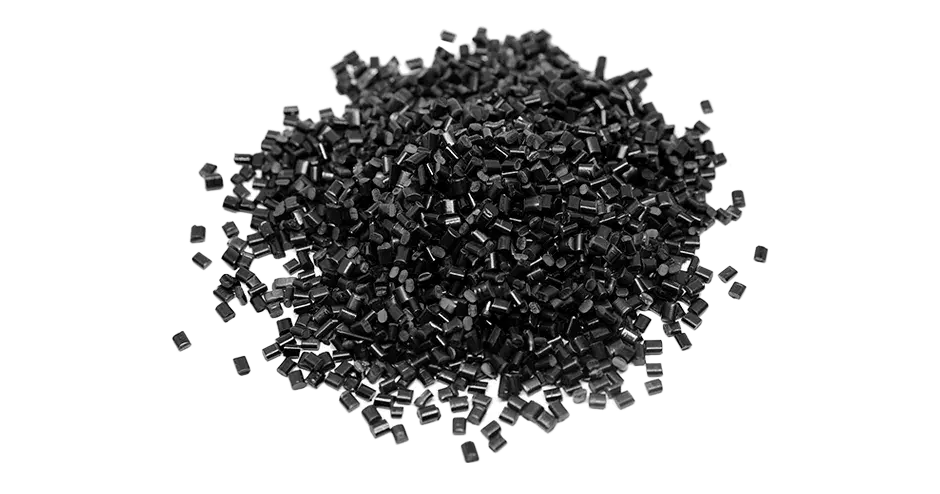

Duo Form now 3D prints thermoforming molds using polymer pellet-extrusion on its EXT Titan 1270 Pellet 3D printer, replacing traditional CNC methods to create ceramic or metal molds. Large-format pellet-extrusion AM uses readily available thermoplastic pellets common to other extrusion manufacturing like injection molding, and which cost up to 10X less than traditional FDM filaments. 3D Systems’ pellet extrusion systems also enable high-throughput printing, with print speeds up to 10X faster than filament systems.

3D Systems and Duo Form identified a grade of glass-filled polycarbonate pellets as ideal for printing thermoform molds; affordable, easily procured, and proven to withstand the thermoforming process as a durable and dimensionally accurate material.

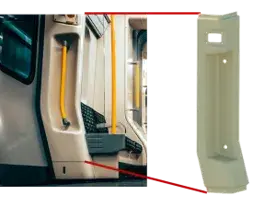

Duo Form also leverages 3D Systems’ printing experience to achieve optimal printing parameters to create molds with the right porosity to function as vacuum passages. This unique ability of additively manufactured molds eliminates the need for special tools to properly form cavities into the thermoformed component, further reducing time and labor costs for producing molds.

Innovation and Design Iteration with AM

Incorporating AM goes beyond the mold-making process for Duo Form. As a leading innovator in its industry, Duo Form also utilizes its EXT Titan 3D printer to quickly print sample parts of final products to present to customers ahead of making the tool. Directly printing parts for design approval before proceeding to the mold-making process has opened the door for faster design iteration and overall shorter lead times.

THE RESULTS

Significant Cost Savings and Reduction in Lead Times

Since implementing AM as part of its manufacturing process, Duo Form says the company has won more business and now closes deals faster thanks to the speed and agility of pellet-extrusion 3D printing. As an example, Rheinheimer shared how Duo Form 3D printed a sample part to present to a customer along with a quote for forming the part. The customer, impressed with the speed and ability to see the final design first, awarded Duo Form the bid that same day. This is now standard practice for Duo Form and brings added value to its customers.

Rheinheimer says he can also see another value AM brings to manufacturers when it comes to storing molds, especially for products that are out of production but may need to be formed in the future for spare parts. With AM, a digital inventory can eliminate the need to store legacy molds, enabling companies to print a new mold when the need arises.

Additive manufacturing complements conventional production processes. Duo Form’s adoption of large-format pellet extrusion 3D printing exemplifies how AM and traditional methods can work together to achieve optimal manufacturing speed, cost management, and quality part production.