Reduce cost and time by 50% for reusable patterns of any complexity and size.

Up to 50%

cost reduction over conventional patterns

2x

faster pattern production

50x50x72"

(1270x1270x1828mm) single-piece patterns

In-house additive manufacturing has become our ‘secret sauce.’ It gives us the advantage over our competitors when it comes to tooling price, accuracy, speed of production, and the ability to modify existing jobs with lightning-fast turnaround times.—Bob Helwer, Engineering Manager, Astech, Inc.

Solving Sand Casting Patterns and Cores Manufacturing Challenges with 3D Printing

Your Partner for 3D Printed Sand Casting Patterns and Core Boxes

Learn More About our Solutions for Sand Casting

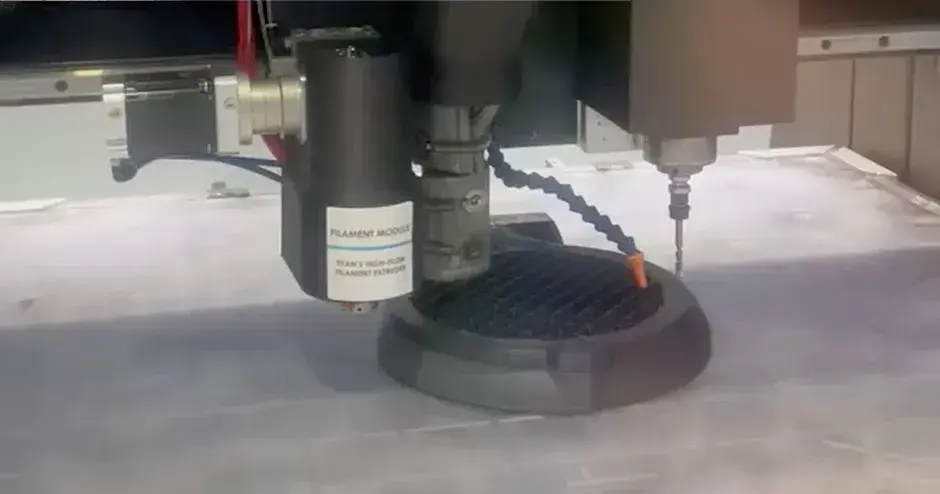

EXT 800 Titan Pellet

Our entry-level industrial pellet extrusion 3D printer with a compact frame that will fit through standard double doors.

EXT 1070 Titan Pellet

3D Systems’ flagship pellet extrusion printer capable of printing medium-to-large format parts, featuring a build volume of 1070mm x 1070mm x 1118mm (42" x 42" x 44").

EXT 1270 Titan Pellet

3D Systems’ largest 3D printer capable of printing full-scale parts up to 6 feet tall with direct pellet-fed 3D printing.

EXT Titan Pellet Materials

Broad selection of commercial, flexible, engineering grade and high-performance polymers for 3D printing