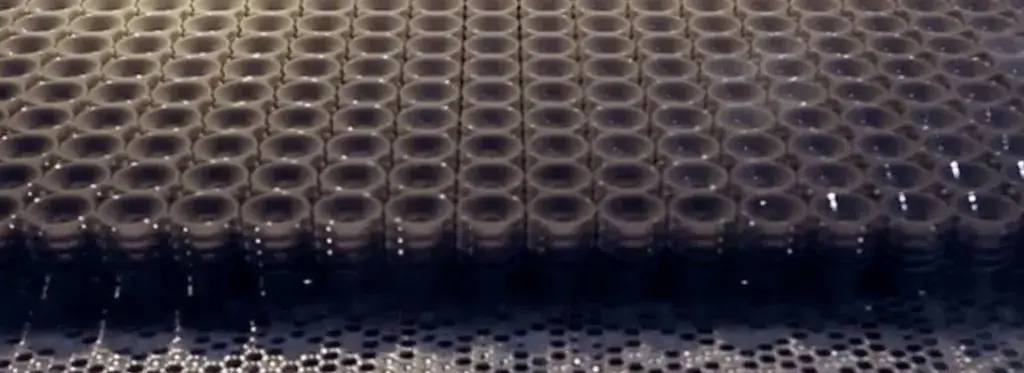

Automation

Figure 4® Production is a customized, integrated digital manufacturing solution with a workflow supported by 3D systems software. Figure 4 Production features up to 15 times faster print speeds than other 3D printing technologies* to facilitate automation for high volume production.