Get 100% silicone parts-in-hands in less than 24 hours or production-grade elastomers in minutes, allowing rapid order fulfillment and faster time-to-market. Deliver end-use part performance, accuracy, and mechanical properties that enable prototypes to bridge production.

100%

silicone prototypes within 24 hours

10x

faster with direct 3D printing capability

Up to 97

Shore A 3D printing elastomers

Solving Soft Material Components Prototyping Challenges with 3D Printing

3D Printing Solutions that Accelerate Innovation

Learn More About our Solutions for Seals and Gaskets

Figure 4

Making 3D Production Real with Scalable, Modular Factory Solutions

Figure 4 RUBBER-65A BLK

Mid tear strength production-grade rubber

ProJet MJP 2500 Plus

MultiJet printing quality, speed and ease of use made accessible

VisiJet M2S-HT250 (MJP)

Up to 250°C heat resistance, strong and rigid material

Figure 4 RUBBER-BLK 10

Durable, hard rubber-like material

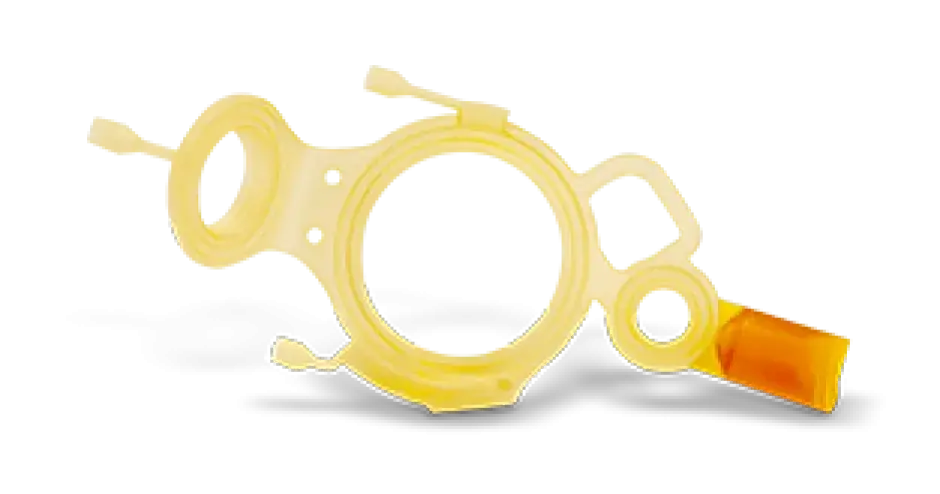

Figure 4 EGGSHELL-AMB 10

Process-optimized material for sacrificial tooling to cast silicone

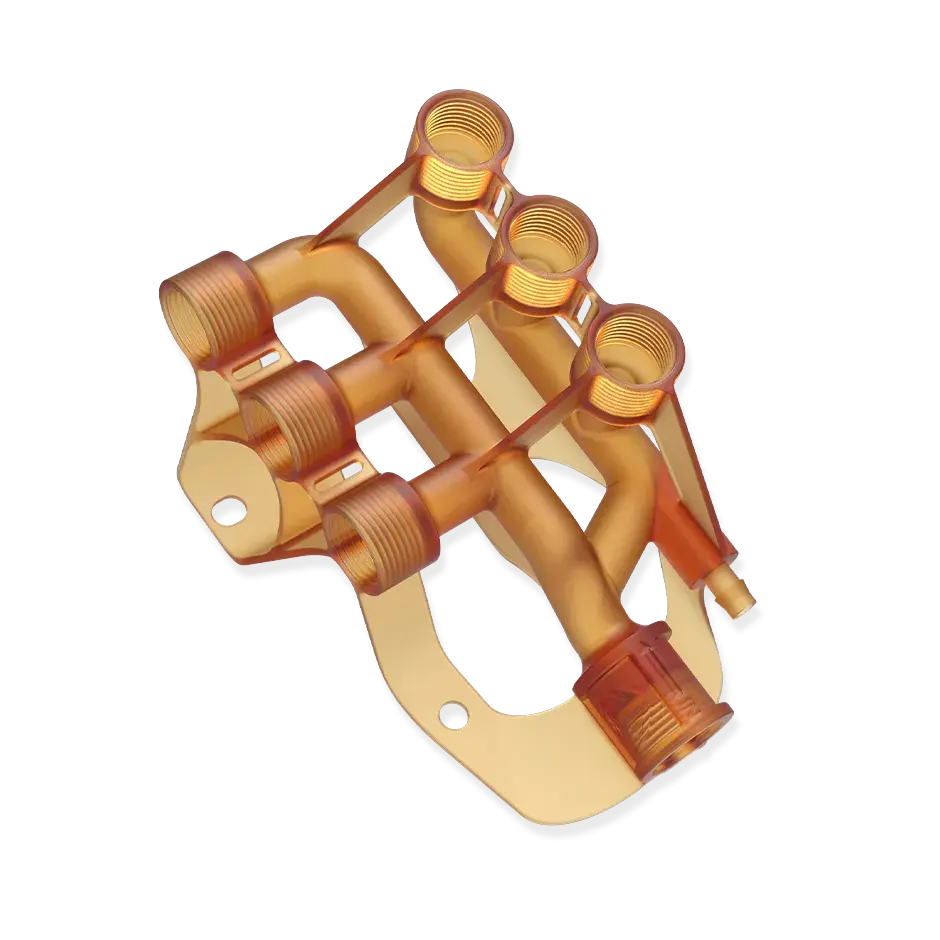

Figure 4 HI TEMP 300-AMB

High temperature resistant translucent plastic with HDT over 300°C

VisiJet M2E-BK70 (MJP)

Tough black elastomer

VisiJet M2 EBK (MJP)

Elastomeric opaque black

ProJet MJP 5600

Large format, multi-material composite parts in a single build

VisiJet CE-BK (MJP)

Elastomeric opaque black