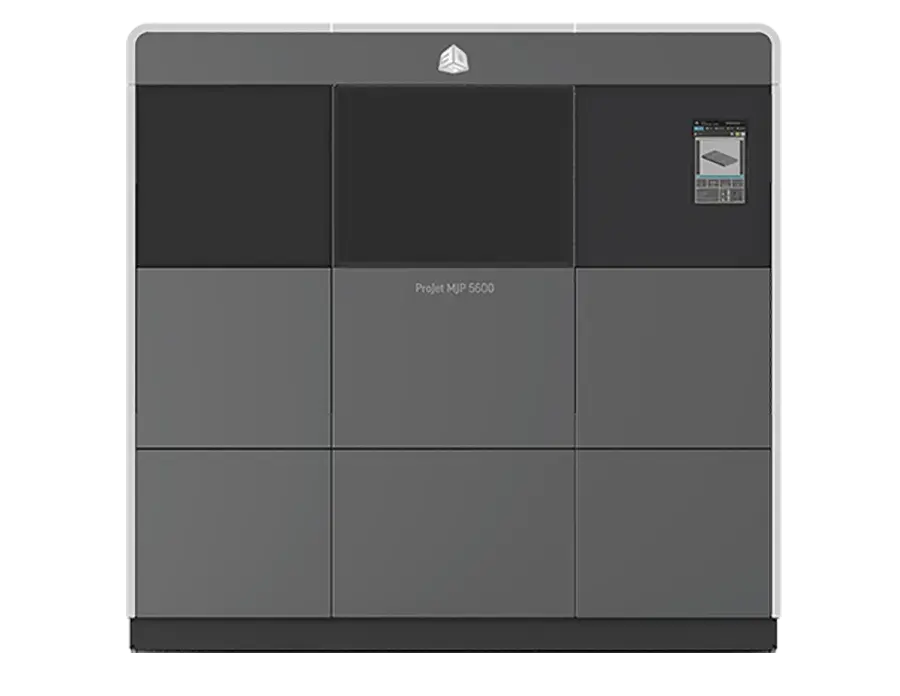

Dozens of MultiJet Material Choices

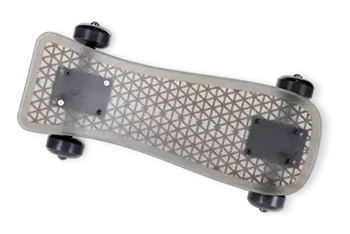

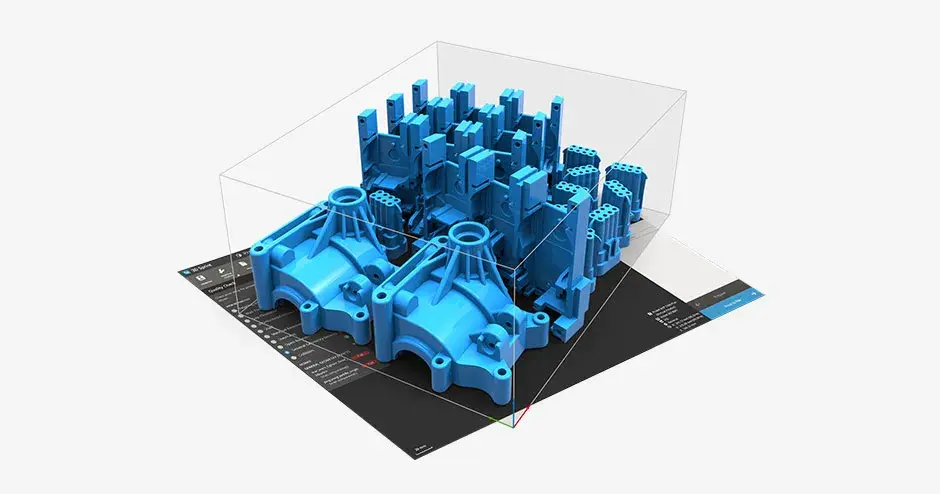

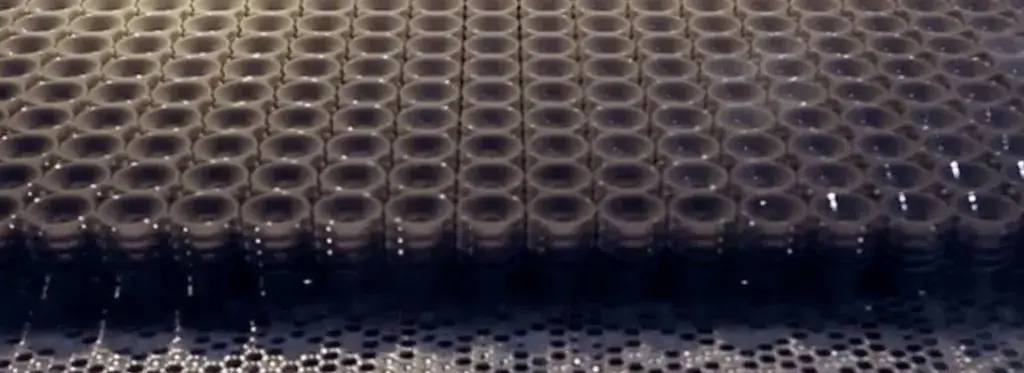

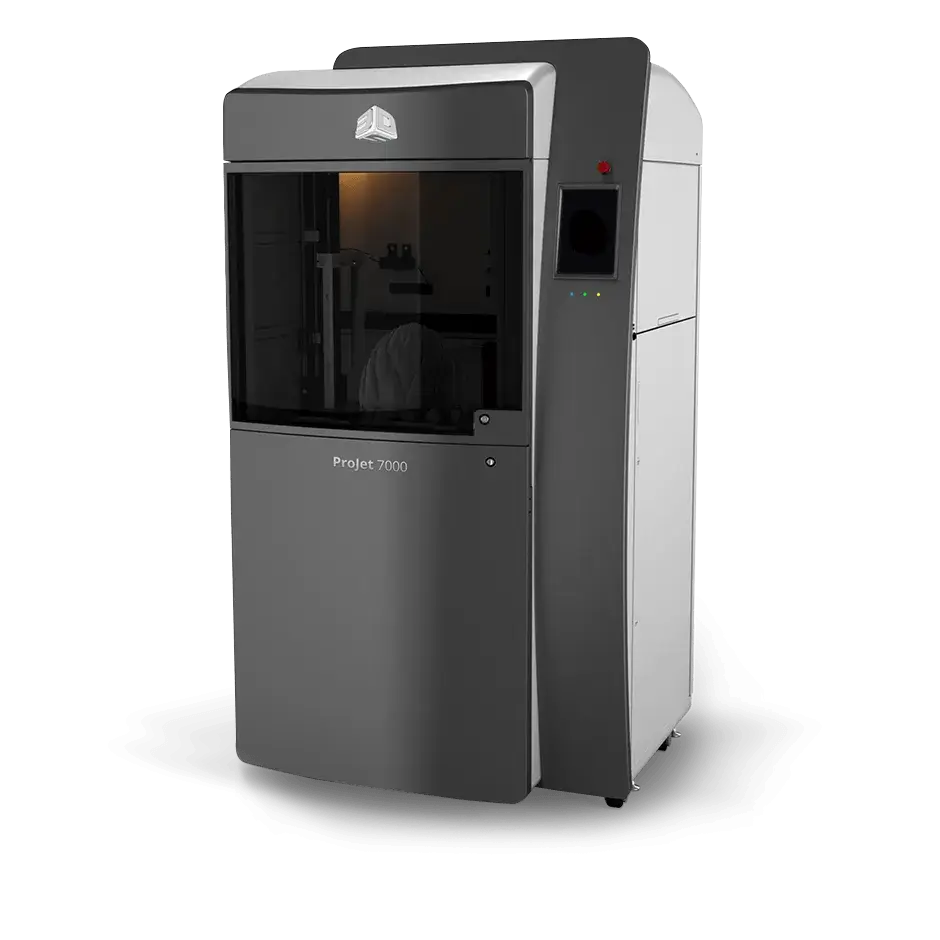

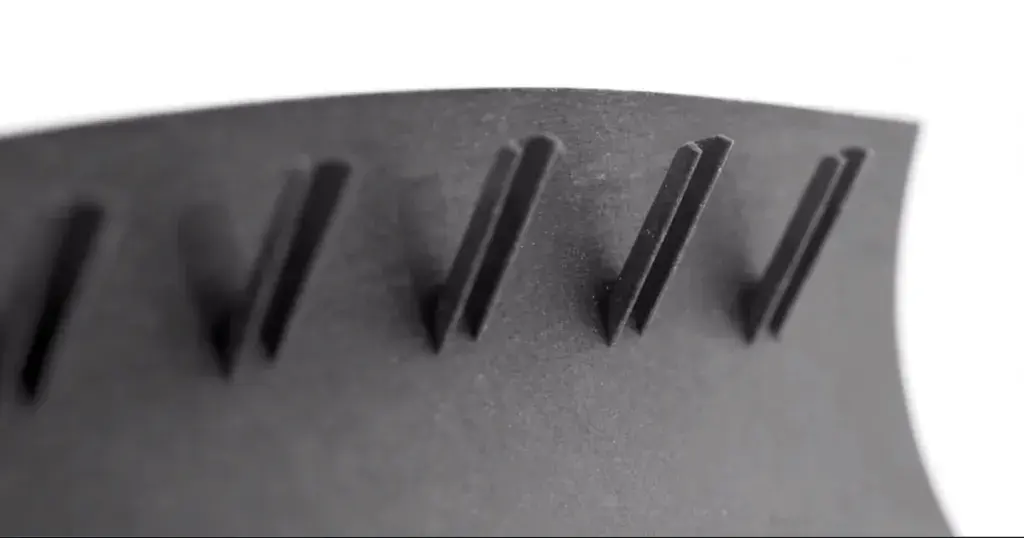

The ProJet® MJP 5600 MultiJet 3D printer solution simultaneously prints and blends both flexible and rigid photopolymers within the VisiJet® family of materials. This is done layer-by-layer at the voxel level, in one part and in a single build, to achieve superior mechanical properties. Additionally, VisiJet rigid plastic, elastomeric and composite materials are engineered for performance with varying degrees of flexibility, material transparency and differentiated shades in one part.