Solving Wearable Components Needs with 3D Printing

3D Printing Solutions that Accelerate Innovation

Learn More About our Solutions for Wearable Components

DuraForm PAx Natural (SLS)

High impact, high elongation nylon copolymer

Figure 4 RUBBER-65A BLK

Mid tear strength production-grade rubber

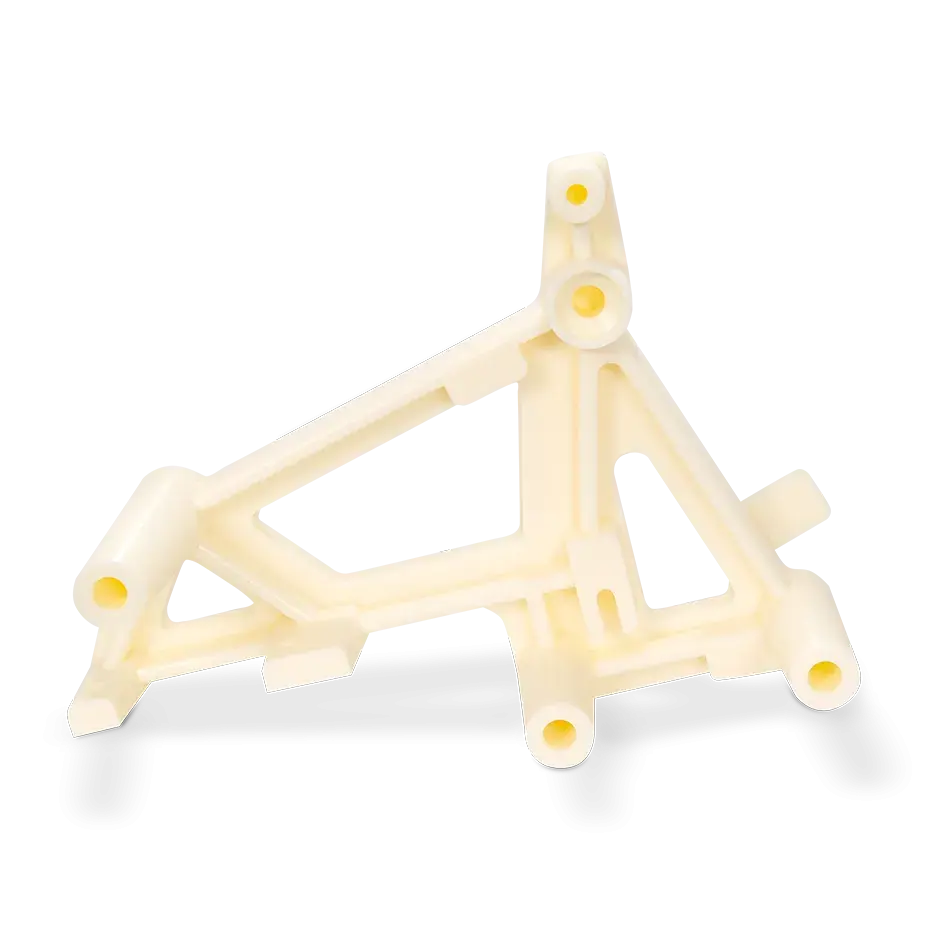

Accura AMX Durable Natural

Production-grade resin featuring long-term environmental stability

Figure 4 Tough 65C Black

Black plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength.

Accura AMX Rigid Black

Production-grade resin featuring long-term environmental stability

Figure 4 PRO-BLK 10

Production-grade, rigid material for production parts

Figure 4 Rigid White

Opaque rigid white production-grade plastic

Figure 4 Tough 60C White

White plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength

Accura ClearVue (SLA)

High clarity plastic, multitude of applications

DuraForm PA

Durable polyamide (nylon) material for production parts

Figure 4 RUBBER-BLK 10

Durable, hard rubber-like material

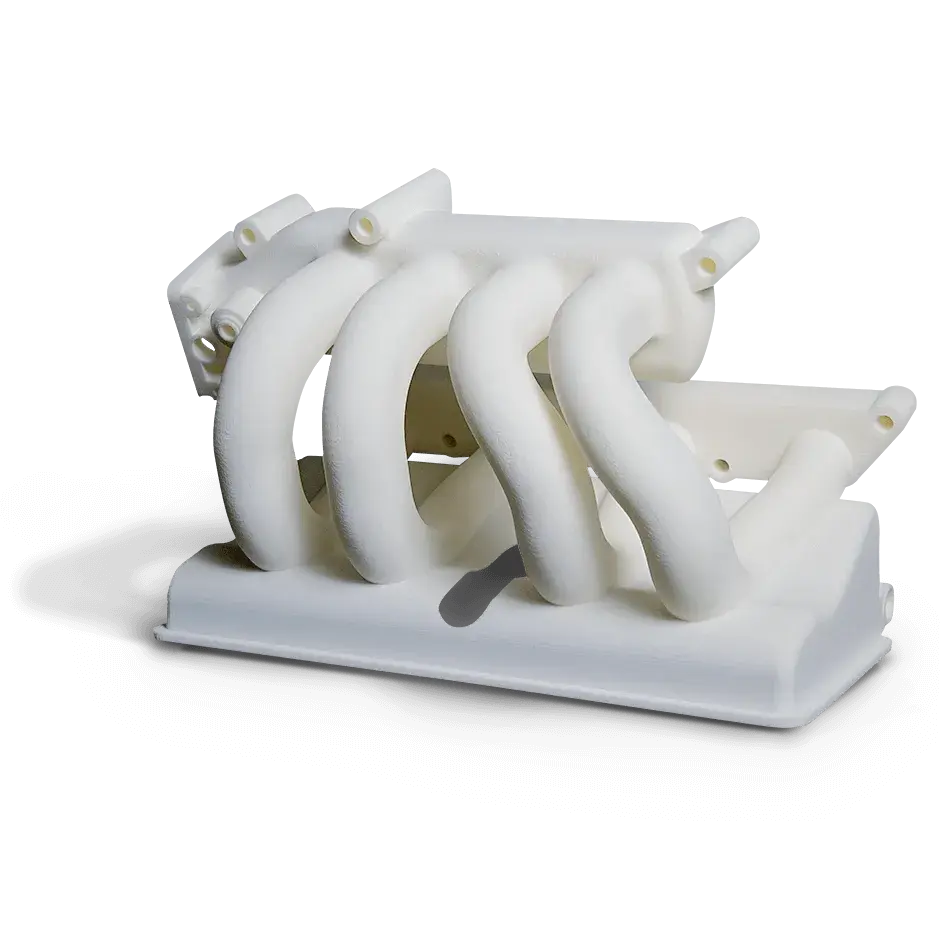

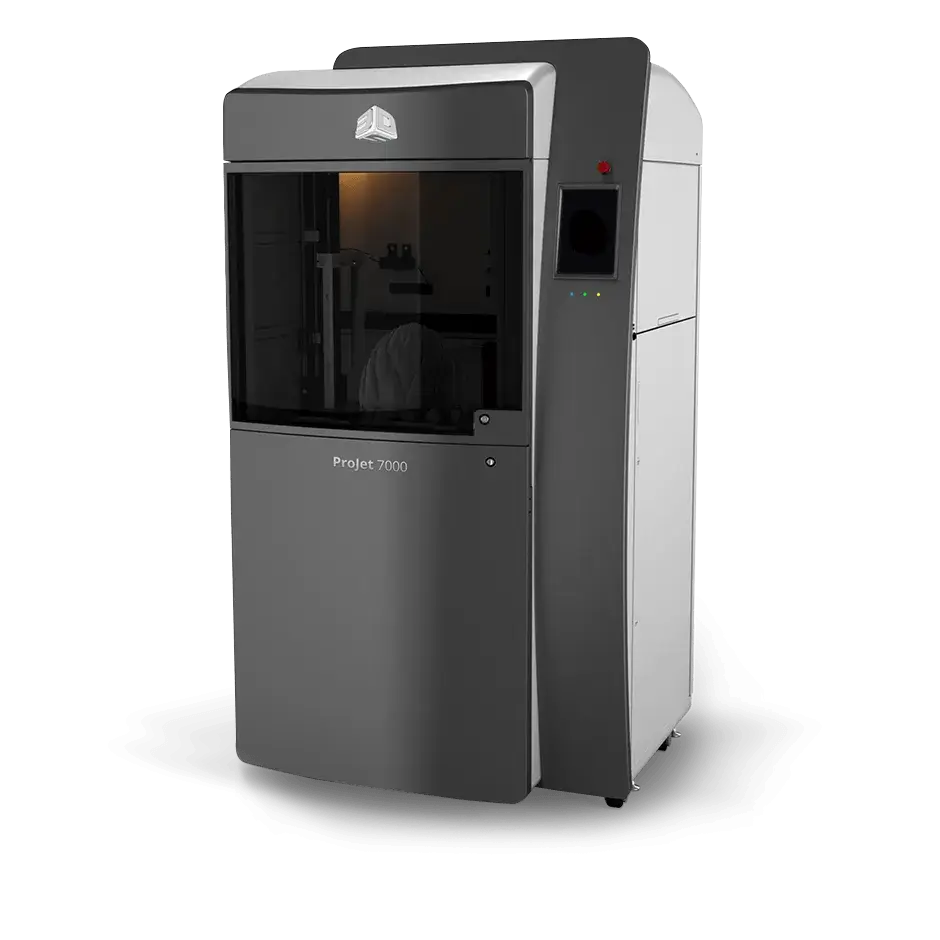

ProJet 7000 HD

Mid-range integrated solution for SLA quality and accuracy

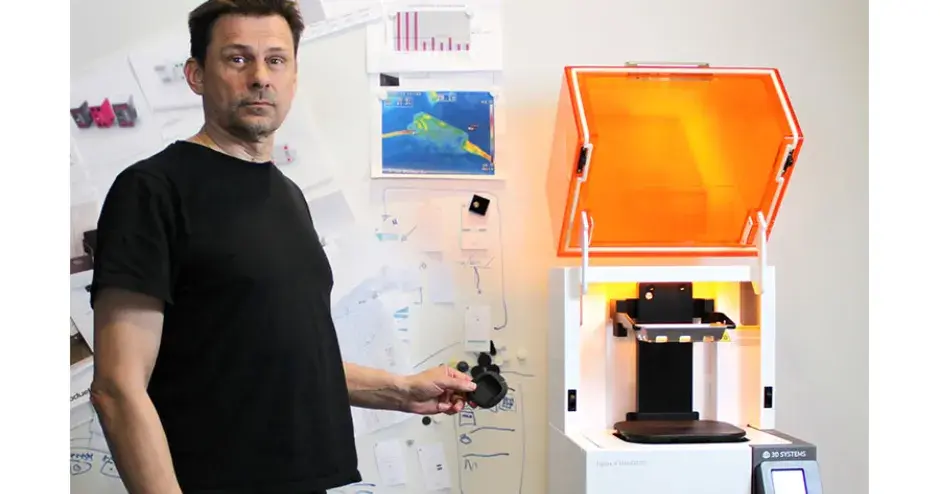

Figure 4

Making 3D Production Real with Scalable, Modular Factory Solutions

ProX 950

All the benefits of SLA 3D printing in extra-large format

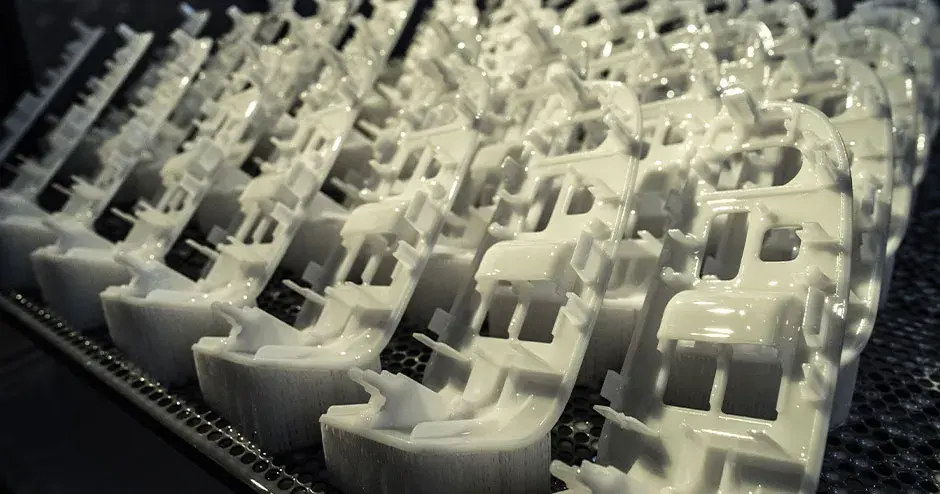

SLS 380

Industrial-scale, process controlled additive manufacturing solution for selective laser sintering