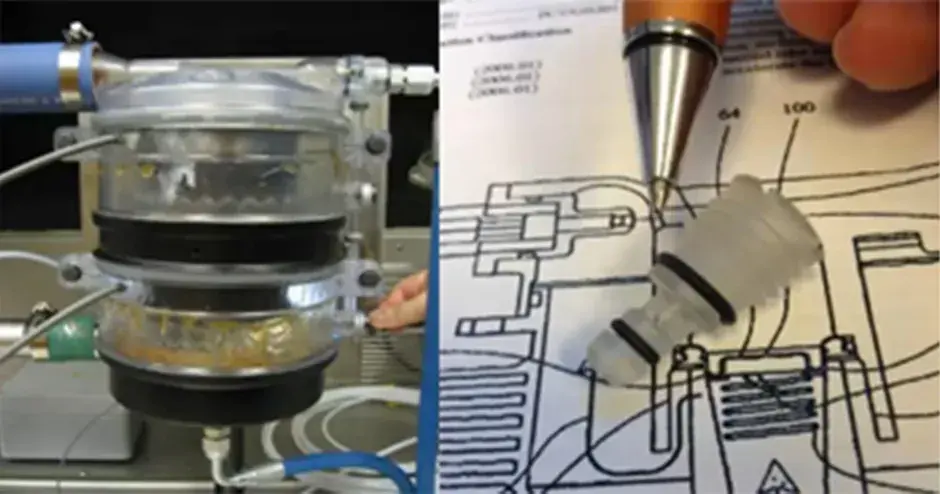

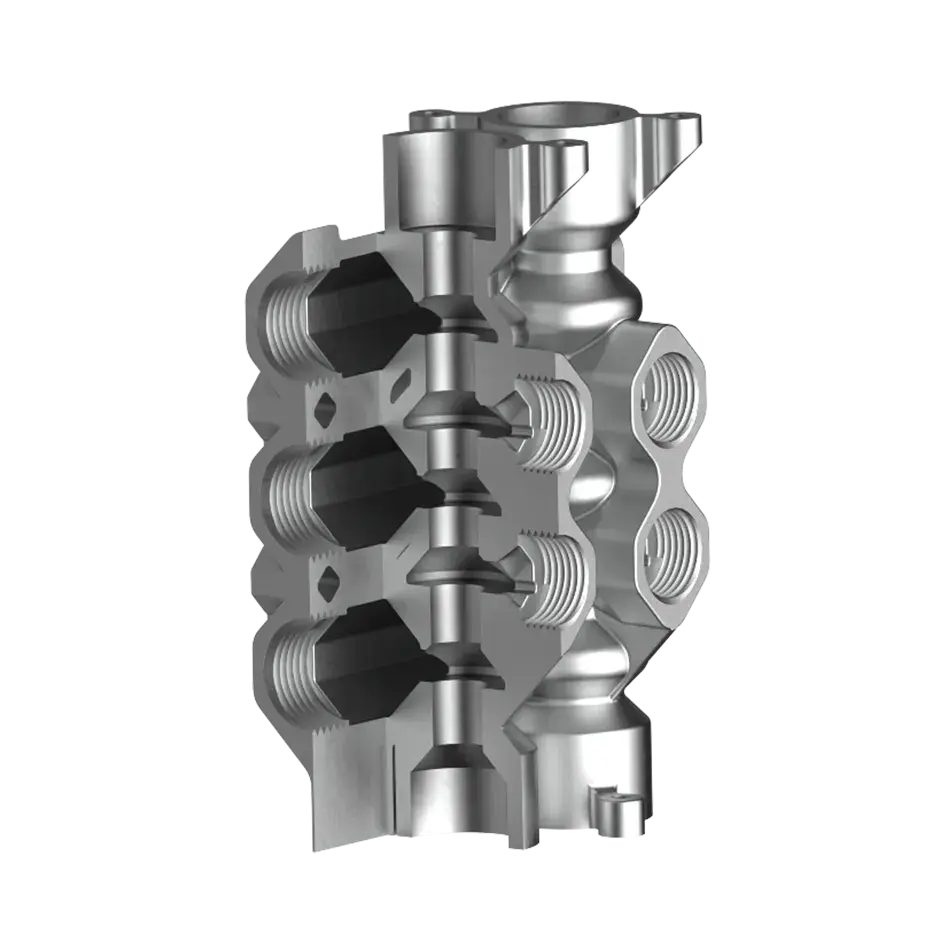

Solve Your Braking Systems and Pneumatic Control Challenges

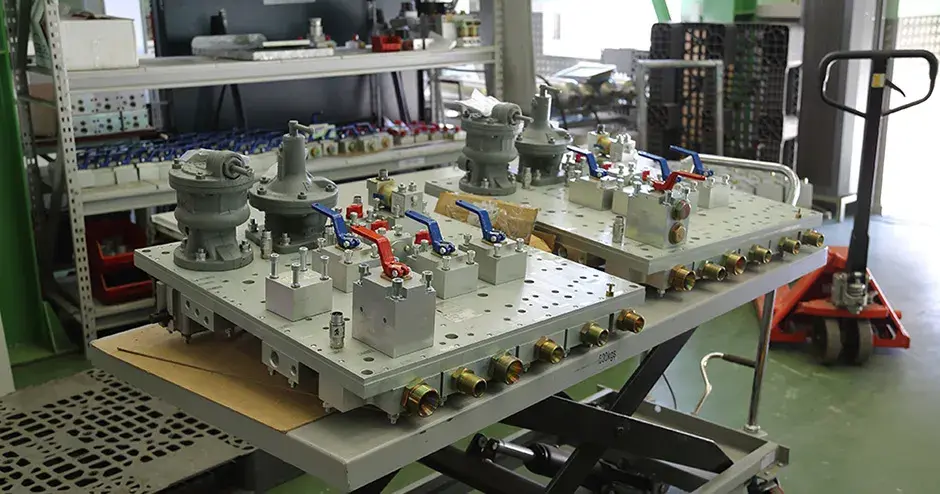

More Truck, Bus & Rail Applications

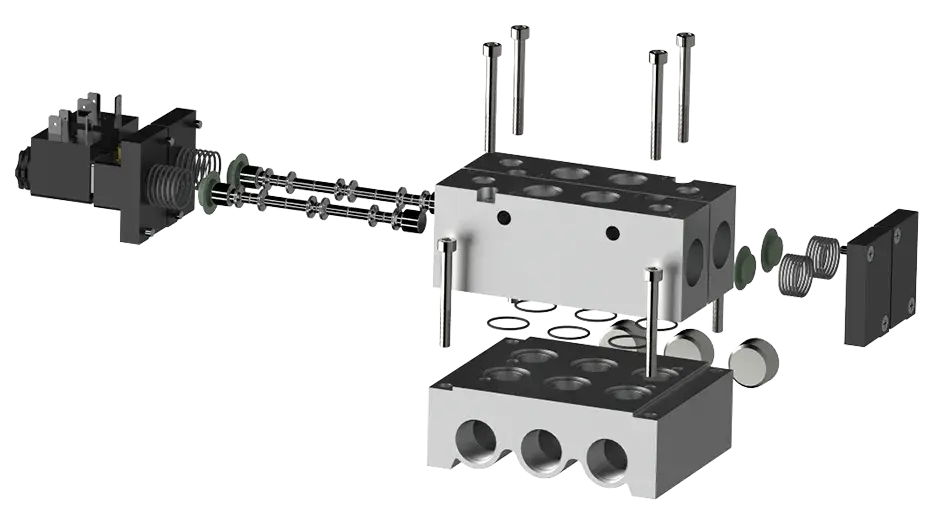

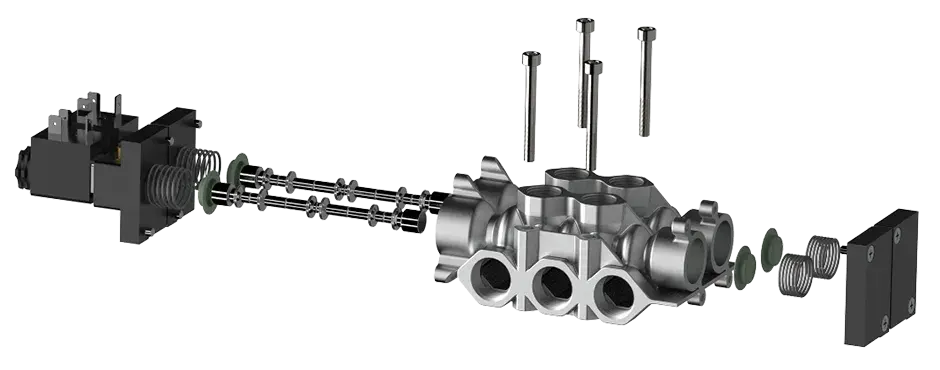

Material, Printer and Software Solutions for Brake Systems and Pneumatic Controls

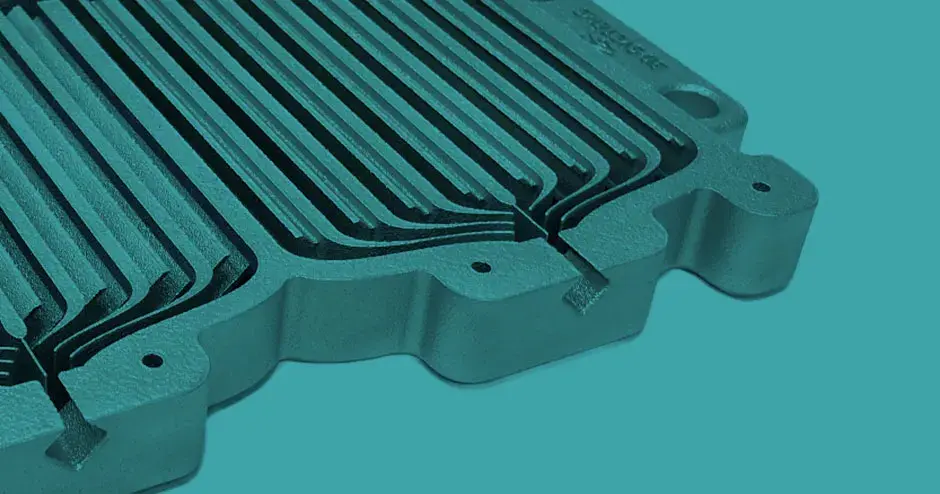

LaserForm 316L (B)

Highly corrosion resistance with good toughness

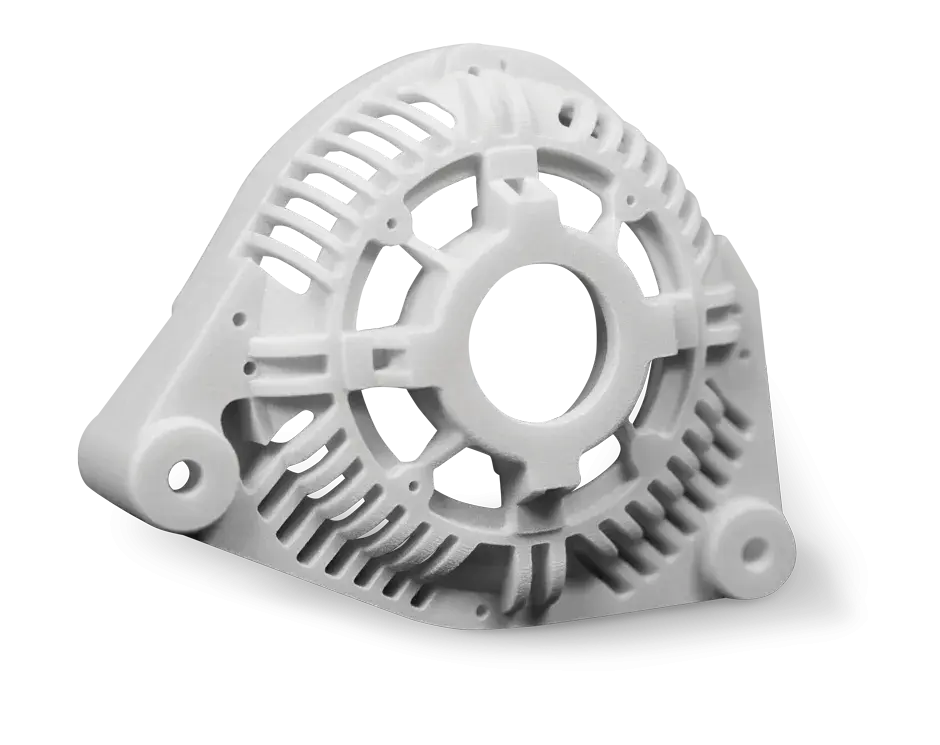

LaserForm AlSi7Mg0.6 (A)

Light weight, good mechanical properties and improved thermal conductivity

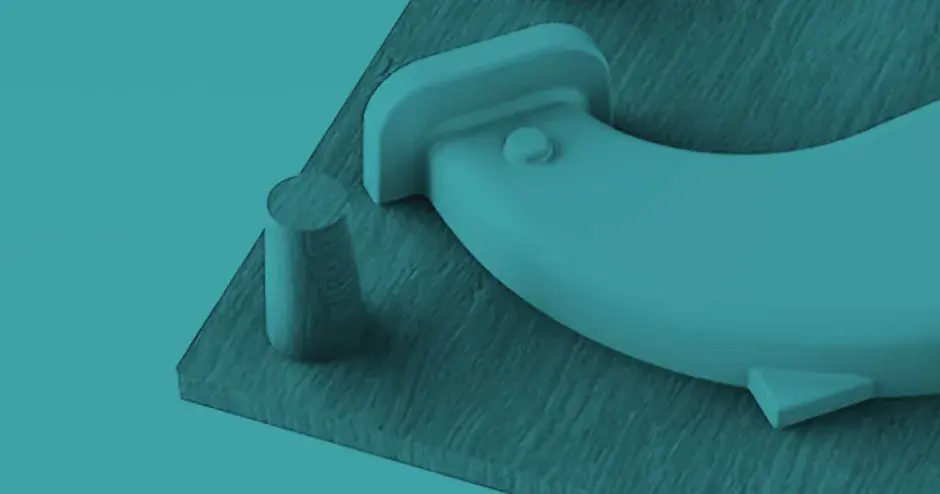

DuraForm ProX HST Composite (SLS)

A fiber-reinforced engineering plastic, high temperature resistance

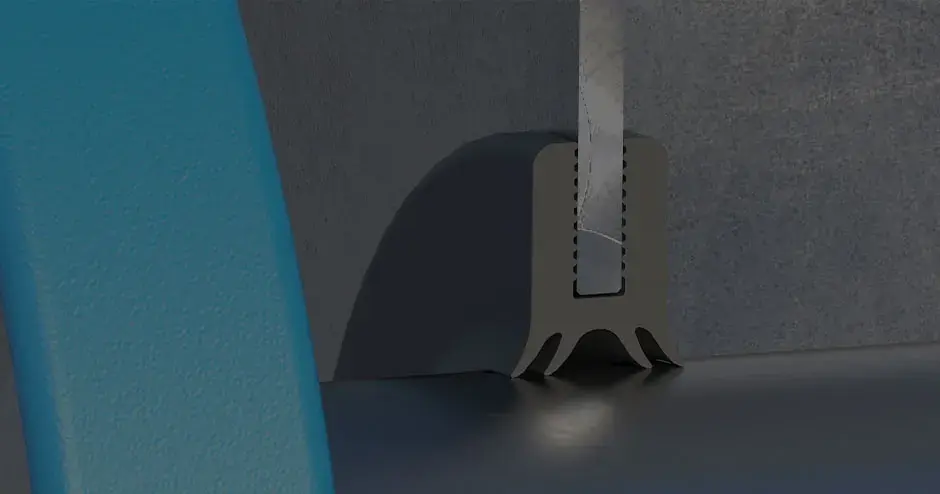

SLS 380

Industrial-scale, process controlled additive manufacturing solution for selective laser sintering

3DXpert

All-in-One Integrated Software for Industrial Additive Manufacturing